Dimensional inspection ensures every copper stamping part meets drawing specifications. Using precision CMMs and measuring tools, our technicians verify accuracy, symmetry, and tolerance consistency before shipment.

HULK Metal provides one-stop copper stamping services with advanced production and inspection equipment. We can produce custom copper stamped parts in various thicknesses and shapes according to drawings or samples. Our professional team ensures precise dimensions, stable quality, and timely delivery, helping bulk buyers achieve more efficient production and better cost control.

ISO 9001 certified.

Advanced equipment and experienced workers.

A fully equipped quality control center.

Timely order delivery.

The larger the order quantity, the greater the discount.

As a metal stamping service supplier with strong production capacity, HULK Metal operates 5 stamping machines with 510-ton capacity, 5 sets of 200-ton machines, 5 sets of 80-ton, and 5 sets of 60-ton presses. We can manufacture custom copper stamping parts from 0.1mm to 10mm thickness. All products can meet CE, SGS, GB, and other certification standards.

Copper stamping parts are produced through advanced stamping technology, which ensures high conductivity, corrosion resistance, and precision forming. HULK Metal offers full-process services including stamping, machining, surface treatment, and inspection. Every batch is manufactured according to drawings and strictly tested to meet customer standards. Packaging, delivery, and after-sales services are also customized to support bulk orders efficiently.

| Name | Copper Metal Stamping Parts |

| Manufacturing Methods | Manufacturing According to Drawings |

| Materials | Copper, Copper Alloy, Brass, and Others |

| Process | Metal Stamping Service: Blanking, Bending, Shearing, Deep Drawing, Expanding, Spinning, Straightening. CNC Machining, Surface Treatment, Quality Control, Packaging, Delivery, After Service. |

| Surface Treatment | Powder Coating, Sandblasting, Brushed, Raw Black / Customized |

| Test Content & Data | 1. Chemical Composition; 2. Mechanical Properties; 3. Inspection of appearance, size, shape, and position tolerance; 4. Surface Quality; |

| Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

| Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

| Delivery Method | Sea / Air / Land |

| Quality Assurance | Life Long |

Copper stamping parts are essential components in electrical, electronic, and mechanical systems where conductivity, formability, and precision are critical. HULK Metal provides complete copper stamping services, from mold design and stamping to surface finishing and assembly. We manufacture custom copper stamped parts in different grades and thicknesses to meet your exact needs, ensuring every order meets global quality and performance standards.

Copper stamping parts are metal components produced through a stamping process using copper or copper alloys as raw materials. This process involves shaping, cutting, bending, and forming sheets under high pressure to achieve specific structures and functions. Due to copper's superior electrical and thermal conductivity, these stamped parts are widely used in electronic devices, automotive systems, power equipment, and communication products. HULK Metal uses advanced presses and precise tooling to produce high-quality stamped copper parts that maintain consistency, tight tolerances, and long-term reliability, helping manufacturers enhance production efficiency and reduce overall operating costs.

Copper Stamping Parts can be classified by application, material, material shape, and part type.

Below are five representative types with descriptions.

Type (Application) | Material | Material Shape | Parts Name | Description |

Electrical Connectors | Pure Copper / Brass | Strip or Sheet | Terminals, Contacts, Busbars | Electrical copper stamping parts are commonly used in terminals, connectors, and contacts due to their high conductivity and oxidation resistance. They ensure stable current flow and reliable connections in power transmission systems, automotive wiring, and communication networks. HULK Metal produces connectors with excellent surface quality and precision, enabling long service life and reduced maintenance costs. |

Automotive Components | Copper Alloy | Sheet / Coil | Sensor Housings, Battery Clips, Shims | Copper stamping parts are used in automotive electrical systems for power distribution and grounding. They help improve electrical performance while maintaining corrosion resistance under harsh conditions. Our stamping factories utilize precision dies and automated presses to maintain consistent dimensions, ensuring compatibility with various vehicle models and assemblies. |

Electronic Components | Copper / Bronze | Strip | Heat Sinks, Frames, Switch Contacts | Stamped copper parts used in electronics have excellent thermal conductivity, providing effective heat dissipation and signal stability. HULK Metal supplies high-precision electronic components suitable for circuit boards, relays, and switches. With tight tolerance control and clean surface treatment, they meet the demanding standards of electronics manufacturing. |

HVAC and Refrigeration Parts | Copper | Sheet | Fittings, Flanges, Brackets | These copper stamping parts are used for air-conditioning, refrigeration, and HVAC systems where corrosion resistance and pressure tolerance are required. We produce fittings and flanges with smooth surfaces and tight sealing capability. Each batch undergoes strict dimensional inspection and leak testing to guarantee performance in fluid or gas systems. |

Lighting and Energy Equipment | Copper / Brass | Sheet / Coil | Reflectors, Frames, Mounting Plates | Copper's reflective and electrical properties make it suitable for lighting and renewable energy products. Our stamped parts are used in lamp housings, solar components, and energy storage systems. They feature high formability, consistent thickness, and fine finish quality, helping OEMs achieve better product aesthetics and energy efficiency. |

Copper stamping parts often require different surface finishes to enhance appearance, corrosion resistance, or conductivity.

Below lists five categories of surface treatment methods with their advantages and typical applications.

Category | Specific Methods | Advantages & Suitable Uses |

Chemical Treatment | Pickling, Passivation, Oxidation Inhibition | Chemical treatments remove oxide scales and impurities from copper surfaces, improving brightness and paint adhesion. Passivation helps resist corrosion and extend service life, while oxidation inhibition prevents tarnish during storage or long-term use. These processes are suitable for copper stamping parts used in decorative or precision electronic applications. |

Electrochemical Treatment | Electroplating, Anodizing, Electro-Polishing | Electrochemical surface treatments create protective coatings or improve electrical conductivity. Electroplating (tin, nickel, or silver) enhances corrosion resistance and solderability, while electropolishing ensures smooth surfaces for better conductivity. These finishes are widely applied to copper connectors, contacts, and electronic assemblies. |

Mechanical Treatment | Grinding, Polishing, Sandblasting, Brushing | Mechanical treatments physically modify the copper surface to achieve the desired texture or smoothness. Polishing and brushing enhance appearance, while sandblasting improves paint adhesion. HULK Metal's surface treatment workshops can achieve consistent finishes suitable for visible parts in lighting, architectural, and automotive applications. |

Electrostatic Adsorption Treatment | Powder Coating, Painting | Electrostatic coating creates uniform, durable finishes that protect copper stamping parts from environmental exposure. Powder coating offers better coverage and longer wear resistance compared to traditional painting. These treatments are ideal for copper components used in outdoor or industrial environments. |

Physical Treatment | Heat Treatment, Coating, Vacuum Plating | Physical treatments improve surface hardness, wear resistance, and aesthetic appeal. Vacuum plating provides decorative metallic layers, while heat treatment stabilizes structure and enhances toughness. These processes are suitable for copper parts requiring both strength and precision, such as in automotive and mechanical applications. |

A professional technical team determines whether a copper stamping factory can meet your complex design requirements. Experienced engineers analyze your drawings, optimize the stamping process, and ensure precision in every detail. HULK Metal's technical team supports product development from design to production to guarantee consistent performance and high manufacturing efficiency.

Has Strong Production Capacity

A strong production capacity ensures stable delivery and supports large-volume orders. HULK Metal has multiple stamping workshops equipped with 510-ton, 200-ton, 80-ton, and 60-ton presses, suitable for manufacturing copper stamping parts of different thicknesses. Automated production lines and well-trained operators maintain high output, short cycles, and reliable consistency across every order.

Strict quality management guarantees the accuracy and durability of copper stamped parts. HULK Metal operates under ISO 9001 certification, combining real-time inspection, process control, and final testing. Our QC center uses precision instruments to measure dimensions, surface quality, and mechanical strength, ensuring every copper stamping part meets international quality standards.

A complete supply chain provides flexibility and cost advantages. HULK Metal works closely with copper raw material factories, tooling partners, and surface treatment suppliers to maintain steady material supply and better pricing. From raw material procurement to packaging, every step is well-coordinated to meet your delivery schedule and quality requirements.

A dependable supplier should offer professional pre-sale and after-sale support. HULK Metal's service team includes engineers, project managers, and logistics specialists who communicate promptly and clearly. We assist clients in evaluating feasibility, optimizing solutions, and ensuring smooth production and delivery, making your copper stamping parts purchasing process easier and more efficient.

Support a Variety of Payment Methods and Delivery Terms

Flexible payment and delivery options demonstrate a supplier's global service capability. HULK Metal supports multiple payment methods such as L/C, T/T, and negotiable terms to suit your trade needs. We also offer various Incoterms including FOB, CIF, and DDP, ensuring your copper stamping parts reach you safely and efficiently.

Support Global Shipping

A qualified copper stamping parts supplier should handle international shipping with efficiency and safety. HULK Metal's logistics team arranges sea, air, or land transport based on your requirements. Our global freight network ensures faster customs clearance, reduced logistics risks, and accurate delivery to over 50 countries and regions worldwide.

Provide Quality Assurance Services

A reliable supplier must stand behind product quality. HULK Metal provides lifelong quality assurance for all copper stamping parts. You can inspect the goods after receipt, and any product with verified quality issues is eligible for return, exchange, or restocking. We aim to safeguard your production stability and long-term cooperation.

A: We ensure quality through a fully equipped inspection center, rigorous process monitoring, and a comprehensive quality assurance system. Every copper stamping part undergoes dimensional, surface, and performance testing to meet required standards before delivery, ensuring stable quality and longer product life.

A: Prices vary depending on several factors, including copper material grade, tolerance, thickness, surface finish, and order quantity. Since HULK Metal owns its own factory, we can provide real-time quotes and more competitive pricing based on your specifications and production needs.

A: All prices are based on consistent high quality. Compared with similar manufacturers, our costs are lower under the same quality standards. Larger orders or long-term cooperation can receive additional price advantages, helping you reduce overall procurement and production expenses.

A: The MOQ depends on several aspects, such as product size, thickness, structure complexity, and processing requirements. You can send 2D or 3D drawings to our engineers (we will sign an NDA), and we'll confirm the minimum order quantity for your copper stamping parts.

A: The delivery time depends on the product type and order quantity. Generally, it takes about 30 days. Larger batch orders improve production efficiency and may shorten the cycle. Normally, the total delivery period will not exceed 45 days. (40 Words)

A: We cooperate with professional surface treatment factories that specialize in powder coating, electroplating, anodizing, and brushing. The right finish depends on material type, thickness, and application of your copper stamping parts. Our engineers will recommend the most appropriate and cost-effective surface treatment solution for your project.

A: We have supplied copper stamping parts to clients in over 50 countries across Europe, North America, South America, Africa, Southeast Asia, and the Middle East. Our logistics network allows smooth delivery and timely customs clearance for bulk shipments worldwide. (40 Words)

A: We operate 510-ton stamping machines capable of producing copper stamping parts in various sizes and shapes. Actual size capability depends on material thickness, structural complexity, and process requirements. Provide your 2D or 3D drawings (under NDA), and our team will evaluate production feasibility.

A: To get a faster quote, please share the following:

2D/3D drawings or physical samples of the copper stamping parts.

Quantity and delivery terms.

Material, surface finish, tolerance, and estimated weight.

If 3D drawings are unavailable, we'll assist in confirming specifications based on your provided details.

A: We accept L/C, T/T, and other flexible payment terms. Delivery options include FOB, CIF, and DDP. If you require other arrangements, our sales and logistics teams will review them to offer a practical, risk-free trade solution that matches your procurement plan.

A: HULK Metal is a professional copper stamping parts manufacturer and OEM/ODM service provider with extensive factory resources. Our integrated team handles production, technical support, procurement, and international trade, providing one-stop service for your copper stamping projects.

HULK Metal's technical team has extensive engineering experience and can accurately interpret drawings, samples, and specifications. By deeply understanding your performance, tolerance, and cost requirements, we can design a more efficient and economical production plan that reduces waste and improves yield.

We maintain long-term cooperation with high-quality copper and brass suppliers to obtain raw materials at lower prices without compromising quality. Our quality inspection team checks each batch for consistency, ensuring every copper stamping part meets required mechanical and chemical standards.

Each production stage follows standardized operating procedures and real-time monitoring. Automated stamping machines and experienced operators ensure accuracy and repeatability. Continuous process improvement and reduced downtime help control costs while maintaining high production efficiency and stable quality for all copper stamping parts.

HULK Metal's inspection center uses CMMs, tensile testers, hardness testers, and microscopes to measure and verify every copper stamping part. Comprehensive inspection throughout production ensures dimensional precision, stable structure, and consistent performance before products are packaged and shipped to customers.

We offer multiple packaging options—wooden cases, cartons, and custom pallets—to prevent damage during transport. Our logistics department selects the most suitable shipping route to minimize freight cost and lead time while ensuring your copper stamping parts arrive in perfect condition.

HULK Metal provides lifetime quality assurance for all copper stamping parts. You can inspect the goods after receiving them, and if any quality issue arises, we offer return, exchange, and restocking services to protect your interests and long-term cooperation.

HULK Metal implements a comprehensive quality control system covering raw material inspection, in-process testing, and final verification. Each copper stamping part is tested for dimensional accuracy, surface finish, and performance stability using advanced instruments. Our QC center strictly follows ISO 9001 standards to ensure each production batch meets international requirements, guaranteeing that every part you receive maintains consistent precision and durability.

Dimensional inspection ensures every copper stamping part meets drawing specifications. Using precision CMMs and measuring tools, our technicians verify accuracy, symmetry, and tolerance consistency before shipment.

Before delivery, HULK Metal performs random sampling and packaging checks to ensure product quantity, labeling, and protection meet client specifications and international export standards.

Mechanical tests measure tensile strength, hardness, and elasticity to ensure copper stamping parts perform reliably under load. Each result is documented for full material traceability.

Quantity inspection confirms the exact number of copper stamping parts in each shipment. Our logistics and QC teams double-check quantities to guarantee accurate, reliable delivery for every order.

Material inspection verifies the copper's chemical composition and purity using spectrometers. This ensures consistent electrical conductivity, corrosion resistance, and mechanical performance across all stamped copper parts.

HULK Metal integrates multiple specialized factories to complete the entire copper stamping production process — from material preparation to final assembly. Each factory operates under ISO 9001 quality management standards and is equipped with advanced machines and skilled workers. Our complete industrial chain ensures faster production cycles, consistent product quality, and more competitive prices for global bulk buyers of copper stamping parts.

The QC center is the foundation of HULK Metal's quality assurance system. It houses advanced testing instruments such as coordinate measuring machines, hardness testers, and metallographic microscopes. Every copper stamping part undergoes multiple inspections during production and before shipment. Our professional inspectors ensure compliance with customer drawings, material specifications, and international standards, delivering reliable and defect-free products every time.

HULK Metal collaborates with experienced surface treatment factories to provide a wide range of finishes, including electroplating, powder coating, brushing, and polishing. Each treatment enhances corrosion resistance, electrical conductivity, or aesthetic value according to application requirements. Strict process control ensures uniform coating thickness and excellent adhesion, allowing every copper stamping part to perform better and maintain a longer service life.

The welding workshop handles assembly and joint processing for stamped copper components that require integration. Our team utilizes MIG, TIG, and resistance welding to ensure firm, clean welds without compromising conductivity. With strict heat control and automated systems, we achieve stable strength and appearance quality. These welded copper stamping parts meet the high-performance demands of automotive, electrical, and machinery industries.

Our stamping factory is equipped with a complete range of presses, including 510-ton, 200-ton, 80-ton, and 60-ton machines, suitable for copper sheets of different thicknesses. Automated feeding systems and precision dies enable high-speed, high-accuracy production. Each copper stamping part maintains stable dimensions and a smooth surface finish, ensuring every batch meets client specifications for industrial and electrical applications.

Our laser cutting workshop provides precise pre-stamping and post-processing support. Equipped with high-power CNC laser machines, we can cut copper plates with complex shapes and tight tolerances. Laser cutting ensures cleaner edges and reduces deformation, improving stamping accuracy and material utilization. This capability allows flexible customization and faster prototype development for your copper stamping projects.

Partnering with HULK Metal means working with a professional copper stamping parts manufacturer capable of delivering higher efficiency, precision, and long-term reliability. From design optimization to full-scale production, every process is completed under strict quality standards. Our technical team can adjust material thickness, surface finish, and tolerance based on project needs, ensuring optimal performance and cost control. With comprehensive supply chain support, we help clients reduce purchasing pressure and maintain consistent production schedules.

HULK Metal will develop production solutions according to your drawings or samples and your requirements of copper metal stamping parts. Our commercial manager will communicate with you whether the content of the solution can meet your requirements, and you can determine the final solution and price.

HULK Metal has smarter stamping machines and experienced production teams. The production teams work strictly according to the production solution. They have rich experience and can operate equipment more proficiently, and can complete copper metal stamping parts faster with higher pass rates.

The metal stamping factory of HULK Metal strictly implements the ISO 9001 quality management system. The quality inspection team will track the production of the order and strictly test the parameters and performance of copper metal stamping parts. Products of your orders can be certified by CE, GB, SGS, etc.

HULK Metal provides packaging, warehousing, freight consulting, and other services to facilitate you to arrange the delivery cycle and the quantity of copper metal stamping parts per shipment. Our freight consulting team works closely with many shipping companies to get better freight rates for you.

HULK Metal is a responsible manufacturer of copper metal stamping parts, we are responsible for the quality of each product in addition to providing high-standard production services. We will properly solve every problem and provide you with a higher standard of quality assurance.

This section introduces practical insights and technical analyses related to copper stamping parts. Topics cover stamping processes, material selection, surface treatment methods, and common application cases. Each article helps engineers and procurement professionals better understand how to improve part performance and reduce costs through optimized design and manufacturing. By sharing professional knowledge, HULK Metal supports global clients in achieving more stable and efficient production systems.

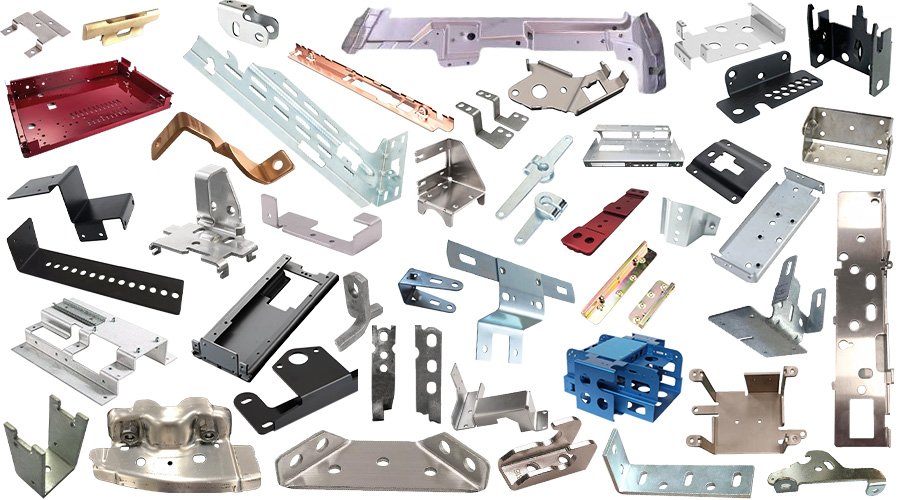

In addition to copper stamping parts, HULK Metal manufactures a full range of metal stamping components using materials such as stainless steel, carbon steel, brass, and aluminum. These products are widely used in automotive, construction, electrical, and machinery industries. With strong production capacity and strict quality assurance, HULK Metal delivers consistent precision and value across all metal stamping categories to meet diverse industrial requirements.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Precision forging is a near-net-shape manufacturing process that creates high-strength components with superior mechanical properties. At HULK Metal, our OEM services integrate advanced hot and cold die forging with precision CNC machining.

HULK Metal provides a comprehensive OEM solution for high-precision forged steel parts, integrating advanced hot and cold forging factories with elite 5-axis CNC machining.

Description HULK Metal provides a vertically integrated manufacturing solution for Motorcycle Forged Parts, specializing in high-strength components like crankshafts, connecting rods, and triple clamps.

Mining environments demand components with exceptional wear resistance. HULK Metal manufactures custom mining forged parts using premium carbon and alloy steels.

ISO 9001-certified metal forging factory. The technical team supports every phase—from print review to process optimization. Faster turnaround without sacrificing accuracy. Full QA with returns/rework guarantee.

Forged gear blanks provide higher strength, better grain flow, and improved fatigue resistance compared with cut gears.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU