We also inspect weld penetration via dye penetrant tests, bolt hole alignment, thread compatibility, and accessory mounting points. Custom requests like logo engraving or color matching are visually confirmed. Nothing leaves without full compliance.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications. With in-house stamping, welding, laser cutting, forging, and casting capabilities, we ensure faster turnaround, lower costs, and consistent quality. Every order comes with full quality assurance—defective or missing items are promptly replaced or replenished. Trust a partner that scales with your business.

1.ISO 9001 certified factories

2.Professional technical team to provide support

3.Finalize your order faster

4.Perfect quality assurance service.

5.Finalize your order at a lower price.

A barbell rack is essential gym equipment designed to safely store and support Olympic bars during strength training. At HULK Metal, we specialize in custom barbell rack OEM services, producing robust, precision-engineered parts tailored to your design. Using advanced metal fabrication techniques and strict quality controls, we deliver racks that combine durability, stability, and clean aesthetics—ideal for commercial gyms, home setups, or fitness brands.

We manufacture custom barbell racks strictly according to your drawings. Our factories work with sheet metal, profiles, strips, and pipes made from iron, steel, stainless steel, or aluminum. Processes include stamping, welding, CNC machining, laser cutting, casting, and forging. Available types range from power racks to wall-mounted units. Surface finishes like powder coating or anodizing are offered. Every part undergoes chemical, mechanical, and dimensional testing. Packaging and global shipping are fully customizable, with lifelong quality assurance on all orders.

Name | Custom Barbell Rack OEM Services |

Manufacturing Methods | Manufacturing According to Drawings |

Materials Size | Sheet Metal, Profiles, Strips, Pipes |

Raw Materials | Iron, Steel, Stainless Steel, and Aluminum. |

Process | Stamping: Blanking, Bending, Shearing, Deep Drawing, Expanding, Spinning, Straightening. Welding, Cutting Casting: Sand Casting, Investment Casting, Lost Foam Casting Forging: Hot Die Forging |

Types | Power Racks, Squat Racks, Half Racks, Wall-Mounted Racks, Functional Training Racks. |

Surface Treatment | Powder Coating, Anodized, Sandblasting, Raw Black / Customized |

Test Content & Data | 1. Chemical Composition; 2. Mechanical Properties; 3. Inspection of appearance, size, shape, and position tolerance; 4. Surface Quality; |

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

Delivery Method | Sea / Air / Land |

Quality Assurance | Life Long |

This section covers everything you need to know about custom barbell rack production at HULK Metal. We explain what barbell racks are, how they’re made, and the full range of types and surface treatments available. You’ll also learn what to look for in a reliable Chinese OEM partner, get answers to common questions, and understand why our integrated factory resources deliver better quality, speed, and value. Whether you’re launching a new fitness line or scaling production, this guide helps you make informed decisions.

A barbell rack is a sturdy frame used in weight training to hold barbells securely during exercises like squats, bench presses, or deadlifts. It enhances safety, organizes equipment, and supports functional training setups. Barbell rack OEM services allow brands to outsource production to specialized manufacturers who build parts exactly to their design specs—without needing their own factory. At HULK Metal, we don’t design the function, but we excel at turning your technical drawings into high-strength, corrosion-resistant, dimensionally accurate racks. Our end-to-end manufacturing capability means you get consistent quality, scalable output, and responsive support—all under one roof.

Production starts with reviewing your drawings, selecting the right process, and sourcing materials. We then fabricate components through stamping, welding, or casting, followed by surface treatment, rigorous inspection, secure packaging, and global shipment—with full after-sales support if needed.

Not every barbell rack part suits the same method. Thick structural uprights may require hot die forging for strength, while intricate brackets might be best stamped or laser-cut. Our engineers analyze your design’s geometry, load requirements, and material to choose the most efficient, cost-effective process—ensuring structural integrity without over-engineering or unnecessary expense.

For stamped or cast parts, we create molds based strictly on your 2D/3D drawings. Our tooling team builds, tests, and refines each mold to eliminate flash, warping, or misalignment. This step ensures repeatability in mass production—so every rack component fits perfectly during final assembly, reducing your downstream fitting issues.

We source iron, steel, stainless steel, or aluminum from vetted mills with certified mill test reports. Before production, every batch undergoes composition verification and mechanical testing. This prevents substandard materials from entering the line—ensuring your racks meet required yield strength, hardness, and ductility for safe, long-term use under heavy loads.

Once approved, we move to full-scale production using automated and semi-automated lines across our stamping, welding, and machining workshops. Real-time monitoring keeps tolerances tight and output steady. Whether you need 500 or 50,000 units, our capacity scales smoothly—without sacrificing consistency or delaying your launch timeline.

Every part passes multiple checks: dimensions via CMM or gauges, weld integrity via visual and penetrant testing, surface finish uniformity, and load simulation where applicable. Only components meeting your specs advance to packaging. This layered approach catches defects early—saving you from costly field failures or returns.

We pack racks to survive long-haul shipping—using wooden crates, reinforced cartons, or bulk skids based on your preference. Each package includes itemized labels and handling instructions. With sea, air, or land options, we coordinate logistics to match your inventory schedule, minimizing port delays or storage bottlenecks.

After delivery, we stand behind every order. If parts arrive damaged, short, or defective, we arrange replacements or restocking at no extra cost. Our team responds quickly to resolve issues—because your satisfaction isn’t just a goal; it’s how we keep long-term partnerships strong.

We produce five main types: power racks, squat racks, half racks, wall-mounted racks, and functional training racks—each built for specific space, load, and usage requirements.

Type | Description |

Power Racks | Power racks are full-frame enclosures designed for heavy squats, bench presses, and safety-bar work. They typically feature four uprights, multi-hole columns, and integrated pull-up bars. At HULK Metal, we build power racks with reinforced base plates and gusseted joints that handle dynamic loads better than basic models. Our laser-cut holes maintain consistent spacing across batches, ensuring compatibility with standard barbell pins and bands. Whether you need a compact home version or a commercial-grade unit, our factories produce frames that feel sturdier and vibrate less under max effort. |

Squat Racks | Squat racks are simpler than power cages, usually consisting of two uprights mounted on a stable base. They’re ideal for gyms prioritizing space efficiency without sacrificing core functionality. We manufacture squat rack uprights from high-yield steel tubing, with wall thicknesses that resist bending over time. The J-cups and safety arms are either welded or bolt-on, depending on your assembly needs. Compared to thinner alternatives, our versions offer greater stability during heavy back squats and reduce wobble noticeably—even on uneven flooring. |

Half Racks | Half racks combine the footprint of a squat stand with added functionality like cable attachments or storage pegs. They’re popular in functional training zones where versatility matters. HULK Metal produces half racks using modular designs that simplify shipping and on-site assembly. Uprights are pre-drilled for accessories, and crossmembers are engineered to minimize flex. Our welding process ensures corner joints stay rigid under lateral stress—making them more durable than many imported units that loosen after months of use. |

Wall-Mounted Racks | Wall-mounted racks save floor space while providing secure bar storage and light-duty lifting support. They’re commonly used in studios, garages, and hotel gyms. We fabricate these from folded sheet metal and structural tubing, anchoring points reinforced to handle shear forces better than typical brackets. Surface finishes are kept simple—often raw black or light powder coat—to match your facility’s aesthetic. Because they’re fully made in-house, we can adjust mounting patterns or add custom slots faster than suppliers relying on third-party workshops. |

Functional Training Racks | Functional training racks integrate pull-up bars, landmine posts, band pegs, and sometimes cable pulley mounts into one robust frame. They support dynamic, multi-planar movements common in HIIT or CrossFit-style programming. HULK Metal builds these with oversized tubing and strategic bracing to absorb impact from kipping pull-ups or rope slams. Every attachment point is tested for torque resistance, and hole layouts follow industry standards for accessory compatibility. The result is a rack that performs more reliably—and lasts longer—than budget alternatives prone to rattling or weld fatigue. |

We offer more than just basic rust prevention—we provide a full range of professional surface finishes to match your brand and environment. While we can deliver parts with raw black or lightly oiled surfaces for clients who prefer to handle final finishing in-house, most customers choose our ready-to-install options. These include durable powder coating in any RAL color (with textured, matte, or gloss finishes), anodizing for aluminum components, sandblasting for uniform texture before coating, and zinc plating for enhanced corrosion resistance in humid or coastal gyms. Our partner treatment factories work under our quality oversight, ensuring adhesion, thickness, and appearance meet commercial-grade standards. Just specify your desired finish, and we’ll integrate it seamlessly into production—so your racks look great and last longer, right out of the box.

Selecting the right OEM partner in China can make or break your product’s success. Not all factories have the technical depth, quality discipline, or service mindset to deliver reliable barbell racks at scale. Below are key factors to prioritize—based on what truly matters in real-world production.

A strong technical team doesn’t just read drawings—they anticipate manufacturing challenges before production starts. At HULK Metal, our engineers review your design for weld accessibility, material efficiency, and structural integrity. They suggest smarter bends, better joint types, or alternative processes that cut cost without sacrificing strength. This proactive support prevents costly rework and delays, turning your concept into a producible, high-performance rack faster.

High demand means nothing if your supplier can’t keep up. Our integrated factories include dedicated lines for stamping, welding, laser cutting, forging, and casting—so we never outsource core processes. This vertical control lets us handle large orders smoothly, maintain consistent quality across batches, and absorb sudden volume spikes. Whether you need 1,000 or 10,000 racks per month, we’ve got the machines, manpower, and floor space ready.

ISO 9001 certification isn’t just a wall plaque—it’s embedded in every step. From raw material logs to final inspection reports, we track everything. Each workstation follows documented procedures, and quality checkpoints are non-negotiable. This system catches deviations early, so defects don’t reach your warehouse. You get predictable, repeatable results—batch after batch—without constant oversight.

Reliable material sourcing is half the battle. We work directly with steel mills and aluminum suppliers who meet strict chemical and mechanical specs, avoiding middlemen markups and inconsistent stock. This tight supply chain ensures shorter lead times, stable pricing, and no surprise shortages. When global markets shift, our long-term partnerships help us secure materials faster than competitors relying on spot purchases.

Great manufacturing shouldn’t end at the factory gate. We offer freight consulting, pre-shipment inspections, documentation support, and responsive after-sales care. If a container arrives short or damaged, we act fast—no finger-pointing. Our team handles everything from customs paperwork to replacement logistics, so you spend less time troubleshooting and more time growing your business.

Flexibility matters. We accept T/T, L/C, and other standard trade terms, and we’re open to discussing options that align with your cash flow or risk management needs. Whether you prefer FOB, EXW, or DDP, we’ll structure delivery terms clearly—so there are no hidden costs or last-minute surprises during shipping or customs clearance.

We ship barbell racks to over 50 countries across North America, Europe, Southeast Asia, the Middle East, and beyond. Our logistics partners specialize in heavy fitness equipment, using reinforced packaging and optimized container loading to minimize damage. With established routes by sea, air, or land, we ensure your order arrives intact and on schedule—no matter where your customers are.

We stand behind every rack we make. If parts arrive with defects, dimensional errors, or surface flaws, we’ll replace them at no extra cost. If quantities are short, we’ll expedite restocking. This isn’t just policy—it’s how we build trust. Lifelong quality assurance means you never bear the risk alone; we share it, every shipment.

We operate a fully equipped in-house quality inspection center staffed by trained technicians. Every batch undergoes rigorous testing—including chemical composition analysis, mechanical property verification, dimensional checks with CMM and gauges, and visual surface inspections. Our ISO 9001-certified system ensures traceability from raw material to finished goods, so defects are caught early and never reach your facility.

Pricing depends on several factors: material type (e.g., mild steel vs. stainless steel), part complexity, tolerance requirements, surface finish, order volume, and packaging. Because we own and operate our factories—without middlemen—we offer real-time, transparent quotes based on your exact drawings. Just share your specs, and we’ll provide a competitive price within 24–48 hours.

All our pricing is built on consistent high quality—never compromised for cost. That said, larger order quantities naturally reduce per-unit costs due to production efficiency and material batching. We also optimize designs for manufacturability when possible, which can lower processing time and waste. Share your target budget, and our team will explore smart ways to meet it without cutting corners.

Minimum order quantity varies based on part size, material, and production method. Small stamped brackets might have an MOQ as low as 200 pieces, while large welded frames could start at 50 units. Send us your drawing (we’ll sign an NDA first), and we’ll evaluate feasibility and give you a clear MOQ—no guesswork.

Standard lead time is around 30 days from order confirmation and deposit payment. Simpler orders may ship faster; complex or very large batches might take up to 45 days. Because we control every step—from cutting to welding to coating—we avoid delays caused by outsourcing. We’ll provide a realistic timeline upfront and stick to it.

We partner with specialized surface treatment factories to deliver powder coating (any RAL color, matte or textured), anodizing for aluminum parts, sandblasting for pre-treatment, zinc plating, and raw black finishes. The best option depends on your rack’s material, environment (e.g., humid gyms), and aesthetic goals. We’ll recommend the most durable, cost-effective solution based on your needs.

We’ve successfully delivered barbell racks to clients in more than 50 countries—including the U.S., Canada, Germany, UK, Australia, UAE, Brazil, Mexico, South Africa, and throughout Southeast Asia. Our logistics network supports sea, air, and land freight, with documentation tailored to local import regulations—so your shipment clears customs smoothly.

Size isn’t the only factor—material thickness, geometry, and process matter too. We’ve made compact wall-mounted brackets under 30 cm and full power rack frames over 2.4 meters tall. If you provide 2D or 3D drawings (we’ll sign an NDA), our engineers will assess producibility based on our equipment capabilities and give you a clear yes or no—plus suggestions if adjustments would help.

A: You can get a quote in a shorter time by providing the following information at once:

1. 2D and 3D drawings of the Barbell Rack. If neither is available, samples can be provided.

2. Quantity.

3. Delivery Terms.

4. Material, surface treatment, tolerance, and weight. If no 3D drawing is available, please provide the following information:

We accept T/T (bank transfer), irrevocable L/C at sight, and other standard international trade terms. Delivery options include EXW, FOB, CIF, or DDP—just let us know your preference. If you have specific contractual or compliance requirements, we’re happy to discuss them and adapt where feasible.

HULK Metal is not a trading company—we’re a direct OEM supplier with deep factory resources across metal fabrication. While we don’t design fitness functions, we manufacture custom barbell rack parts exactly to your specifications using our own stamping, welding, laser cutting, casting, and forging workshops. Our team includes technical, procurement, and export specialists who manage your order from drawing review to final delivery.

At HULK Metal, quality isn’t an afterthought—it’s built into every stage of production. Unlike brokers or limited-capability shops, we combine deep technical insight, tight supply control, and rigorous process discipline to deliver barbell racks that perform reliably under real-world stress. Here’s how we consistently raise the bar.

Our professional technical team has years of experience interpreting fitness equipment drawings and translating them into manufacturable parts. We don’t just follow specs—we ask questions to understand your usage environment, load expectations, and assembly process, so the final product fits seamlessly into your system and meets end-user demands.

We’ve built long-term relationships with top-tier steel and aluminum mills, ensuring consistent material quality and stable pricing. This integrated supply chain reduces lead time variability and eliminates the risk of substandard substitutes—so every rack starts with verified, high-grade raw stock.

Before any metal enters production, it undergoes chemical and mechanical testing against your requirements. Our procurement team works only with certified suppliers, and every batch comes with mill test reports. This upfront verification prevents defects at the source—saving time, cost, and rework downstream.

Every workstation follows standardized operating procedures under ISO 9001 guidelines. Welders are certified, laser cutters are calibrated weekly, and stamping dies are maintained daily. This discipline ensures repeatability—so the 1,000th rack matches the first in dimensions, strength, and finish.

Parts go through multiple inspection gates: incoming material checks, in-process dimensional verification, weld integrity tests, and final pre-shipment audits. Only components that pass all criteria move forward—giving you confidence that what arrives matches what was agreed.

We design packaging to protect heavy, sharp-edged racks during long ocean voyages—using reinforced cartons, wooden crates, or custom palletizing. Each shipment includes clear labeling, packing lists, and handling instructions, reducing damage risk and speeding up your warehouse intake process.

Once your shipment arrives, inspect it at your pace. If anything’s damaged, short, or out of spec, just let us know—we’ll arrange replacements or restocking immediately, no hassle. Your satisfaction doesn’t end at delivery; we’re with you until every rack is perfectly in place.

At HULK Metal, quality control isn’t a final checkpoint—it’s woven into every phase of barbell rack production. From material verification to pre-shipment audits, our multi-layered inspection system ensures dimensional accuracy, structural strength, surface consistency, and packaging integrity. Every batch is traceable, every defect logged, and every corrective action documented. We don’t just meet standards—we enforce them daily, so your racks perform safely and reliably under the heaviest loads, year after year.

We also inspect weld penetration via dye penetrant tests, bolt hole alignment, thread compatibility, and accessory mounting points. Custom requests like logo engraving or color matching are visually confirmed. Nothing leaves without full compliance.

We use CMMs, calipers, gauges, and laser scanners to verify every critical dimension against your drawings. Tolerances as tight as ±0.1mm are achievable. No part moves forward until it matches your specs—ensuring a perfect fit during final assembly.

Every incoming metal batch is checked for chemical composition via spectrometer and cross-referenced with mill certificates. This prevents substitution errors and guarantees your racks are built from the exact alloy and grade you specified.

Before loading containers, we conduct random sampling based on AQL levels. Items are checked for function, finish, labeling, and packaging integrity. Photos and reports are shared upon request—so you approve before shipment sails.

Tensile strength, yield point, and hardness are verified through lab testing on sample batches. We ensure your racks can handle dynamic loads without deformation or failure—especially critical for safety arms, uprights, and base frames.

We count and tag every unit during packing. Packing lists are double-checked against POs. If your order includes 500 J-hooks, you’ll receive exactly 500—no shortages, no guesswork, no last-minute surprises at your warehouse.

Trained inspectors examine every surface for scratches, pinholes, uneven coating, or weld spatter under controlled lighting. Powder coat thickness and adhesion are tested per ASTM standards. Only flawless finishes leave our factory.

HULK Metal doesn’t outsource—we own and operate every critical workshop needed to build premium barbell racks. From laser-cut uprights to forged safety pins, welded frames to powder-coated finishes, our factories work under one roof with synchronized workflows. This vertical integration means tighter quality control, faster turnaround, and lower costs. Whether you need stamping precision or heavy-duty forging, we’ve got the machines, the manpower, and the mastery to deliver exactly what your design demands—no compromises.

When your barbell rack needs precision-machined holes, threaded inserts, bearing mounts, or custom fittings—we handle it in-house with industrial-grade CNC mills and lathes. Our machines hold tolerances down to ±0.02mm, ensuring perfect alignment for moving parts or accessory attachments. Whether it’s drilling safety pin slots, counterboring bolt heads, or machining cam-lock interfaces, every cut is programmed, verified, and inspected. No outsourcing. No guesswork. Just tight-tolerance metalwork that fits, functions, and lasts—exactly as your drawings require.

When brute strength matters—like for bar catches, safety pins, or heavy-duty hinges—we turn to hot die forging. Solid steel billets are heated and pressed into shape under extreme tonnage, aligning grain structure for maximum toughness. No porosity. No weak spots. Just pure, directional strength. After forging, parts are trimmed, heat-treated, and machined to spec. This process outperforms casting or machining alone for high-stress applications—giving your racks the kind of durability commercial gyms demand.

Looks matter—but protection matters more. Our partnered surface treatment lines offer industrial-grade powder coating, anodizing, zinc plating, and sandblasting—all managed under our QC standards. Powder coats are applied evenly, cured at precise temperatures, and tested for adhesion and impact resistance. Anodized aluminum parts resist corrosion in humid environments. Even raw black finishes get oil-rubbed protection for short-term rust prevention. We don’t just coat—we engineer finishes to survive sweat, chalk, drops, and daily abuse while keeping your brand looking sharp.

This is where trust gets built. Our in-house quality control center runs chemical analyzers, tensile testers, hardness gauges, CMMs, and surface profilers. Every production batch pulls random samples for destructive and non-destructive testing. Inspection reports are archived for traceability. If a dimension drifts or a coating fails, production halts until root cause is fixed. We don’t guess—we measure, log, and verify. Because when your customer loads 500 lbs onto a rack, there’s no room for “almost good enough.”

Welding is where strength gets built—and we treat it seriously. Our certified welders use MIG and TIG processes to join structural tubing, base frames, and crossmembers with full penetration and minimal distortion. Fixtures hold parts in perfect alignment during welding to prevent warpage. Post-weld, seams are ground smooth, checked for porosity or cracks, and stress-relieved where needed. Whether it’s a squat rack’s upright-to-base joint or a power rack’s multi-point connection, we ensure every weld can handle years of heavy drops and dynamic loads.

Our high-speed stamping lines handle everything from small J-hooks to large base plates with consistent accuracy. We use 100–500-ton presses paired with hardened tool steel dies that last thousands of cycles without wear-induced drift. Engineers optimize blank layouts to reduce material waste, and every stamped part is deburred and inspected for burrs, warping, or dimensional deviation. If your rack needs brackets, sleeves, or mounting flanges, our stamping team delivers them fast, flat, and flawlessly aligned—ready for welding or assembly.

Precision starts here. Our fiber laser cutters slice through steel and aluminum sheets up to 25mm thick with ±0.05mm accuracy—perfect for intricate gussets, logo panels, or custom hole patterns like Westside spacing. Nesting software minimizes scrap, and automatic loading/unloading keeps throughput high. Every cut edge is smooth, square, and ready for bending or welding without secondary finishing. Need a unique silhouette or branded cutout? Just send the DXF file—we’ll make it real, fast and clean.

For complex, load-bearing components like footplates, cam locks, or specialty fittings, we use sand casting and investment casting to achieve dense, void-free metal structures. Patterns are CNC-machined for repeatability, and molten metal is poured under controlled conditions to avoid shrinkage or inclusions. Castings are then heat-treated, machined to final tolerance, and surface-prepped for coating. Unlike generic foundries, we inspect every piece for internal integrity via ultrasonic testing—so your cast parts won’t crack under pressure.

Choosing HULK Metal means partnering with a true OEM production powerhouse—not a middleman or limited workshop. We deliver complete barbell rack solutions faster, cheaper, and more reliably because we control every step in-house. From raw steel to final packaging, our factories run under one roof with ISO-certified discipline. You get consistent quality, scalable output, responsive support, and lifelong assurance. When performance, timing, and cost matter, we’re the partner that delivers—batch after batch, year after year.

We don’t piece together your order from scattered subcontractors—we handle everything internally: laser cutting, stamping, welding, forging, casting, surface treatment, inspection, and global shipping. This end-to-end control eliminates communication gaps, delays, and quality drift. Whether you need a simple wall-mounted rack or a fully accessorized power cage, we produce every component to your drawing—with full traceability and zero handoffs. That’s real OEM service: seamless, accountable, and built for brands that demand consistency at scale.

No waiting for third-party shops to free up capacity. Our dedicated production lines prioritize your order from day one. Integrated workflows mean no bottlenecks between cutting, bending, welding, and finishing. Need a rush? We’ll re-sequence schedules without charging premium fees—because your success is ours. Typical lead time is 30 days, but we’ve shipped complex racks in 21 when deadlines demanded it. Speed isn’t luck—it’s built into our system.

Direct factory access + smart material use + high-volume efficiency = real cost savings. We buy steel in bulk, nest laser-cut parts to minimize waste, and automate repetitive tasks—all without sacrificing quality. Unlike trading companies adding markup, we pass savings straight to you. Bigger orders unlock better rates, but even mid-size batches benefit from our lean processes. And because we catch defects early, you avoid hidden costs from returns, rework, or customer complaints down the line.

Our production system follows ISO 9001, but we build to your standards—whether that’s ASTM F2218 for commercial fitness equipment, EN 957 for European markets, or your own internal specs. Material certs, weld logs, coating thickness reports, and load-test data are all available on request. We don’t just say “it’s strong”—we prove it with documentation that satisfies auditors, insurers, and safety regulators. So whether you’re selling to gyms, schools, or government buyers, your racks come backed by verifiable compliance.

We treat every order like a long-term partnership—not a one-time transaction. Need help interpreting a tolerance? We’ll explain it. Shipment delayed by weather? We’ll reroute it. Parts damaged in transit? We’ll replace them—no argument. Our team includes technical advisors, logistics coordinators, and multilingual sales reps who respond within hours, not days. From first quote to final delivery (and beyond), you’re never left wondering who to call. That’s service built for real business—not just paperwork.

Looking for deeper insights into barbell rack production? Our resource section covers everything from material selection and welding best practices to surface treatment comparisons and global shipping tips. Whether you’re sourcing for the first time or optimizing an existing supply chain, these guides help you ask the right questions, avoid common pitfalls, and work smarter with your Chinese manufacturer. No fluff—just practical, factory-floor knowledge you can use to build better racks and stronger partnerships.

Beyond barbell racks, we manufacture a full range of heavy-duty gym components: weight plate trees, dumbbell racks, cable crossover pulley systems, lat tower frames, landmine attachments, band pegs, and Olympic bench supports. All parts are built using the same precision stamping, laser cutting, and welding processes—with matching finishes and load ratings. If you’re expanding your fitness line or bundling equipment, we can produce every metal component under one roof. Consistent quality. One point of contact. Zero compatibility headaches.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

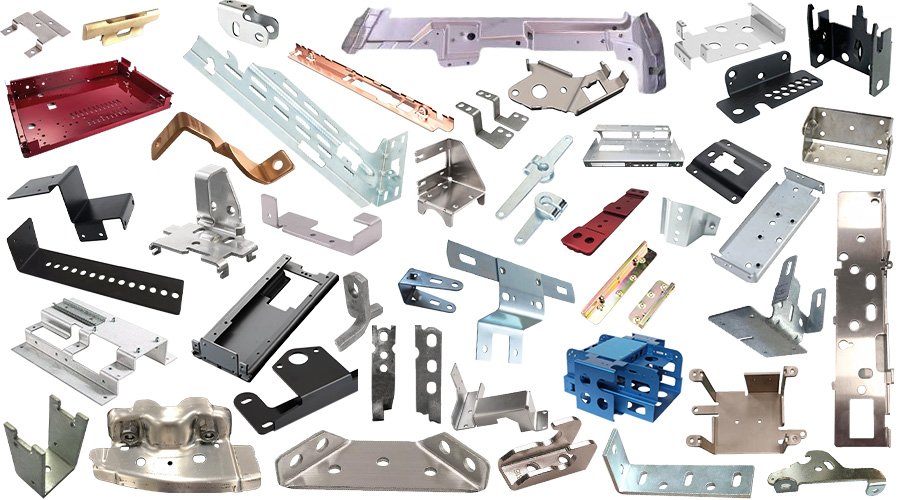

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU