We use CMMs, optical comparators, and precision gauges to verify critical dimensions, tolerances, and geometric relationships against your drawings—ensuring perfect fit during assembly and reliable performance under real-world riding conditions.

HULK Metal delivers high-quality CNC machined bike parts with tight tolerances, advanced surface finishes, and full OEM support. Our ISO 9001-certified factories use 3-, 4-, and 5-axis machining to produce cranks, hubs, brake components, and custom brackets—backed by rigorous quality control, competitive pricing, and global shipping. From prototype to mass production, we ensure every part meets your exact specifications, on time and without compromise.

1.ISO 9001 Certified Bicycle Part Machining Factory

2.Professional Technical Team to Provide Support

3.Finalize Your Order Faster

4.Perfect Quality Assurance Service.

5.Finalize Bicycle Part Machining at a Lower Price.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers. As an ISO 9001-certified CNC bike parts supplier, we specialize in OEM production of complex components like crank arms, derailleur hangers, stem clamps, and custom brackets. Our factories use 3-, 4-, and 5-axis CNC machines to ensure every part meets your exact specifications, on time and at competitive pricing.

HULK Metal produces CNC machined bike parts from aluminum, steel, stainless steel, alloy steel, and iron, following your exact drawings. Our processes include CNC turning, milling, drilling, grinding, and polishing—plus casting, forging, and stamping when needed. We machine critical components like cranks, hubs, brake brackets, and sprockets, then apply finishes such as anodizing or powder coating. Every part undergoes rigorous checks for dimensions, material composition, and surface quality. Packaging and delivery are fully customizable, backed by lifelong quality assurance and responsive after-sales support.

Name | Bicycle Part Machining |

Manufacturing Methods | Manufacturing According to Drawings |

Raw Materials | Iron, Steel, SS (Stainless Steel),Alloy Steel, Aluminum |

Process | Casting, Forging, Cutting, Stamping. CNC Machining: Turning, milling, polishing, grinding, drilling, and reaming, and so on Packaging, Delivery, After Service. |

Surface Treatment | Galvanized, Passivation, Powder Coating, Shot Blasting, Polishing, Anodizing, etc. |

Parts Types | Bicycle gears, freewheels and sprockets; handlebar seatposts and seatpost clamps; bearing housings and wheel hub parts; brake calipers and brackets; pedals and cranks. |

Test Content & Data | 1.Chemical Composition; 2. Mechanical Properties; 3. Inspection of appearance, size, shape, and position tolerance; 4. Surface Quality; |

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

Delivery Method | Sea / Air / Land |

Quality Assurance | Life Long |

This section dives deep into the world of bicycle part machining—from what it is and how CNC bike parts are made, to real-world applications, surface treatments, and key factors when choosing a China supplier. It also explains why HULK Metal consistently delivers higher quality through technical expertise, strict production control, and a fully integrated supply chain—ensuring your components are precise, durable, and ready for global markets.

Bicycle part machining is the precision manufacturing process used to produce high-performance, durable components for bicycles—from road and mountain bikes to e-bikes and cargo models. Unlike mass-produced stamped parts, CNC machined bike parts are crafted with exacting tolerances to ensure optimal fit, function, and weight savings. These components often include crank arms, bottom brackets, derailleur hangers, stem clamps, hub shells, brake calipers, and custom adapters that demand complex geometries and superior surface finishes.

The process relies heavily on computer numerical control (CNC) technology, where raw metal—typically aluminum alloys like 6061 or 7075, stainless steel, or alloy steel—is shaped using multi-axis lathes and mills. This allows for intricate features such as internal threading, tapered bores, and lightweight pocketing that traditional methods can’t achieve consistently. Because bicycles operate under dynamic loads and environmental stress, every machined part must meet strict standards for dimensional accuracy, material integrity, and fatigue resistance.

At HULK Metal, bicycle part machining isn’t just about cutting metal—it’s about engineering reliability into every component. Our ISO 9001-certified factories combine advanced 3-, 4-, and 5-axis CNC equipment with decades of production experience to deliver parts that perform flawlessly in real-world riding conditions. Whether you need low-volume prototypes or high-volume production runs, we follow your drawings precisely and support your project from raw material selection through final inspection. With tight control over every step—and a commitment to zero-defect delivery—we help brands build better bikes without compromise.

CNC machined bike parts are made by transforming metal stock into precision components through a structured workflow: selecting the right process, building custom tooling, sourcing certified materials, running controlled production, conducting multi-stage inspections, and delivering with tailored packaging—all backed by responsive after-sales support.

Before production begins, our technical team reviews your drawings and functional requirements to select the most efficient and cost-effective method. For complex geometries like hollow cranks or integrated brake mounts, 5-axis CNC machining is ideal. Simpler brackets may use 3-axis milling or turning. We also evaluate whether casting or forging should precede machining to optimize material use and structural strength—ensuring performance without unnecessary cost.

Custom fixtures and jigs are essential for holding bicycle parts securely during high-speed machining—especially for thin-walled or asymmetrical components. Based on your drawings, we design precision tooling that guarantees repeatability across thousands of units. After fabrication, each fixture undergoes trial runs and adjustments to eliminate vibration, misalignment, or deformation, ensuring consistent quality from the first piece to the last.

We source certified raw materials—such as aerospace-grade aluminum or corrosion-resistant stainless steel—from trusted suppliers. Every batch undergoes incoming inspection: verifying chemical composition, mechanical properties, and surface condition. This prevents defects before machining even starts and ensures your CNC bike parts meet both industry standards and your specific performance expectations.

Once setup is approved, full-scale production begins under strict process controls. Our CNC machines run 24/7 with real-time monitoring to maintain tolerances as tight as ±0.01mm. Operators and supervisors track cycle times, tool wear, and in-process dimensions to prevent drift. This disciplined approach allows us to deliver large orders of CNC machined bike parts on schedule—without sacrificing precision or consistency.

Every finished part undergoes multi-point inspection: CMM for critical dimensions, visual checks for surface defects, hardness testing, and thread verification. We document all results and share reports upon request. If any unit falls outside your tolerance range, it’s quarantined immediately. This rigorous quality gate ensures only compliant parts move to packaging—protecting your brand’s reputation.

We offer customized packaging—anti-rust paper, foam inserts, individual boxing, or bulk cartons—to prevent damage during transit. Orders ship via sea, air, or land based on your timeline. Our logistics team coordinates documentation, customs clearance, and tracking so your CNC bike parts arrive safely, on time, and ready for assembly or distribution.

If any issue arises post-delivery—whether dimensional discrepancy, surface flaw, or shortage—we respond within 24 hours. HULK Metal provides returns, exchanges, or restocking at no extra cost. Our goal isn’t just to fulfill orders, but to build long-term partnerships by standing behind every part we machine.

CNC machined bike parts are vital across road, mountain, e-bike, and cargo bicycles—delivering strength, precision, and lightweight performance. From drivetrain components to brake systems and frame fittings, these parts ensure reliability, safety, and smooth operation under demanding riding conditions.

Application Category | Detailed Description |

Drivetrain Components | Crank arms, chainrings, bottom brackets, and freewheels require extreme dimensional accuracy and fatigue resistance. CNC machining ensures perfect concentricity, thread integrity, and balanced weight distribution—critical for power transfer efficiency. At HULK Metal, we machine these from high-strength aluminum alloys or steel using 4- and 5-axis CNC centers, achieving surface finishes that reduce friction and wear. Tight tolerances prevent chain drop and noise, while precise bolt-circle diameters guarantee compatibility with major groupsets. Every drivetrain part undergoes hardness testing and runout inspection to meet ISO 4210 standards for bicycle safety. |

Braking Systems | Brake calipers, mounting brackets, and lever pivots must withstand high stress and thermal cycling without deformation. We produce these CNC machined bike parts from stainless steel or heat-treated aluminum to ensure consistent clamping force and corrosion resistance. Complex internal channels for hydraulic lines or precise bore alignment for mechanical pivots are achieved through multi-axis machining. Surface treatments like anodizing or passivation enhance durability in wet conditions. Each component is inspected for flatness, hole position, and thread quality to prevent brake fade or failure—ensuring rider safety on steep descents or in urban traffic. |

Frame & Handlebar Fittings | Stem clamps, seatpost collars, headset spacers, and dropout inserts demand flawless fit and clamp integrity. Even minor deviations can cause slippage or frame damage. Using CNC turning and milling, we produce these parts with micro-tolerances (±0.02mm) and smooth clamping surfaces that distribute pressure evenly. Materials like 6061-T6 aluminum offer the ideal balance of stiffness and weight. We also machine custom adapters for integrated cockpits or e-bike displays. All fittings undergo torque testing and visual inspection to eliminate burrs or sharp edges that could scratch carbon frames or compromise safety during aggressive riding. |

Wheel & Hub Assemblies | Hub shells, axle end caps, quick-release skewers, and disc rotor mounts must rotate true and resist lateral loads. CNC machining ensures perfect bearing seat concentricity and precise rotor mounting surfaces—key for disc brake performance. We use hardened alloy steel or aerospace-grade aluminum, machining internal splines and external flanges in a single setup to maintain alignment. Post-machining, parts receive shot blasting or anodizing for wear resistance. Every hub component is checked with dial indicators for runout and CMM for critical dimensions, guaranteeing smooth rolling and long service life even under heavy loads or off-road abuse. |

Pedals & Custom Accessories | Platform pedals, clipless pedal bodies, and bespoke mounts for racks, fenders, or bottle cages combine function with aesthetics. These CNC machined bike parts often feature complex contours, knurling for grip, and internal threading—all produced in one operation to avoid misalignment. Lightweight yet durable materials like 7075 aluminum are preferred for high-end applications. We also offer custom engraving or color-anodized finishes for brand differentiation. Rigorous load testing simulates real-world shear and torsion forces, ensuring every pedal or bracket stays secure mile after mile. |

HULK Metal offers a full range of surface treatments for CNC machined bike parts—including electrochemical, chemical, mechanical, physical, and electrostatic processes—to enhance corrosion resistance, wear performance, aesthetics, and longevity. Each method is selected based on material, function, and environmental demands.

Treatment Category | Processes Included | Detailed Description |

Electrochemical | Anodizing (Type II & III), Hard Anodizing, Electroplating (Nickel, Zinc, Chrome) | Electrochemical treatments like anodizing create a controlled oxide layer on aluminum bike parts—boosting hardness, wear resistance, and dye adhesion. Type III hard anodizing is ideal for high-friction components like pedal bodies or brake levers, achieving surface hardness up to 60 HRC. Electroplating with zinc or nickel provides sacrificial or barrier protection for steel parts such as bolts or axle caps. All processes follow strict bath chemistry and voltage controls to ensure uniform thickness and adhesion. Post-treatment sealing prevents staining and enhances corrosion resistance, especially critical for e-bike or coastal-use components exposed to moisture and road salts. |

Chemical | Passivation, Chemical Film (Alodine/Chromate Conversion), Phosphating, Black Oxide | Chemical surface treatments modify metal at the molecular level without electricity. For stainless steel bike parts like derailleur hangers or bolts, passivation removes free iron and enriches the chromium oxide layer—maximizing rust resistance. Aluminum components receive chromate conversion coatings (e.g., Alodine) for paint adhesion and mild corrosion protection when anodizing isn’t needed. Phosphating prepares steel for powder coating by creating a micro-porous base that improves bonding. Black oxide offers a sleek, non-reflective finish for internal brackets while adding minimal dimensional change. These eco-friendly, low-cost options are perfect for functional parts where appearance is secondary to reliability. |

Electrostatic Adsorption | Powder Coating, E-coating (Electrophoretic Deposition) | Electrostatic methods apply durable polymer finishes that resist chipping, UV fading, and chemicals. Powder coating is widely used on visible bike parts like stem caps, chain guards, or custom brackets—offering matte, gloss, or textured finishes in any RAL color. Charged powder particles adhere evenly to grounded metal, then cure under heat to form a seamless, thick (60–120μm) protective layer. E-coating provides ultra-uniform coverage—even inside cavities—making it ideal for complex frames or hidden mounts. Both processes enhance corrosion resistance far beyond paint, with zero VOC emissions. At HULK Metal, we match your brand colors and meet outdoor durability standards for long-term performance. |

Mechanical | Shot Blasting, Sandblasting, Bead Blasting, Vibratory Finishing, Brushing | Mechanical surface treatments refine texture, remove burrs, or prepare parts for further finishing. Shot blasting with steel grit strengthens aluminum crank arms through compressive stress, improving fatigue life. Bead blasting creates a soft satin finish on handlebar clamps or hub shells—ideal for premium aesthetics without glare. Vibratory tumbling deburrs intricate pedal cages or sprocket teeth, ensuring smooth operation and rider safety. Brushing adds directional grain to faceplates for a consistent industrial look. These dry, non-chemical methods are fast, controllable, and often used as pre-treatment before anodizing or as final finishes for minimalist designs where raw-metal appeal matters. |

Physical | Polishing (Mirror & Satin), Laser Etching, PVD Coating (optional) | Physical treatments alter surface topography or deposit ultra-thin functional layers. Mirror polishing on aluminum seatpost clamps or stem faces delivers a high-luster, premium appearance, while satin polishing offers subtle refinement. Laser etching permanently marks logos, torque specs, or part numbers without affecting structural integrity—perfect for traceability. Though less common in standard bike parts, PVD (Physical Vapor Deposition) can apply titanium nitride or DLC (diamond-like carbon) coatings for extreme wear resistance on high-end pivot pins or bushings. These techniques combine visual appeal with performance, tailored to brands seeking differentiation through detail and durability. |

When sourcing CNC machined bike parts from China, not all suppliers deliver the same level of reliability, precision, or support. To avoid costly delays, quality issues, or communication breakdowns, it’s essential to evaluate a factory beyond just price. Below are critical factors that separate capable partners from the rest.

A strong technical team doesn’t just operate machines—they interpret your drawings correctly, suggest DFM (Design for Manufacturing) improvements, and troubleshoot potential issues before production starts. At HULK Metal, our engineers review every dimension, tolerance, and material callout to ensure feasibility. This expertise prevents miscommunication, reduces scrap rates, and helps finalize your order faster—especially for complex parts like integrated brake mounts or hollow cranks.

High-volume orders demand more than a few CNC machines. Look for factories with scalable capacity: multiple 3-, 4-, and 5-axis centers running in parallel, dedicated shifts, and buffer inventory for raw materials. HULK Metal’s network includes ISO-certified factories equipped to handle everything from prototype batches to monthly runs of 50,000+ units—ensuring consistent lead times without compromising quality or precision.

ISO 9001 certification isn’t just a badge—it’s proof of documented processes for every stage: incoming inspection, in-process checks, and final QA. At HULK Metal, we enforce statistical process control (SPC), calibrate tools weekly, and retain traceability records for every batch. This systematic approach catches deviations early, so your bicycle parts meet exact specifications—every time, without exception.

A reliable supplier controls more than machining—it integrates raw material sourcing, surface treatment, packaging, and logistics under one roof. HULK Metal works with vetted metal suppliers and in-house finishing partners, eliminating handoff risks. This vertical coordination shortens lead times, ensures material certifications are valid, and allows quick adjustments if design changes arise mid-production.

From initial quoting to post-delivery support, seamless service matters. Our team includes sales engineers, quality inspectors, logistics coordinators, and after-sales specialists—all fluent in English and responsive within 24 hours. You won’t get lost in translation or wait days for answers. This end-to-end ownership means fewer headaches and faster resolution when you need it most.

Flexibility in commercial terms builds trust. HULK Metal accepts T/T, L/C, PayPal (for samples), and negotiates Incoterms like EXW, FOB, or DDP based on your preference. Clear contracts outline payment schedules, inspection rights, and delivery windows—so there are no surprises. This transparency is especially valuable for first-time buyers navigating international procurement from China.

Your parts must reach assembly lines or warehouses worldwide—on time and undamaged. We coordinate sea, air, and land freight through trusted carriers, handle export documentation, and provide real-time tracking. Whether shipping to Germany, the U.S., or Australia, our logistics team ensures customs clearance is smooth and delivery aligns with your production schedule.

Mistakes happen—but how a supplier responds defines the partnership. HULK Metal offers lifelong quality assurance: if parts arrive damaged, out of spec, or short-shipped, we arrange returns, replacements, or restocking at no extra cost. Every batch comes with an inspection report, and we stand behind our work with accountability—not excuses. That’s how we earn long-term trust from global bike brands.

We operate a fully equipped in-house quality inspection center with CMMs, spectrometers, hardness testers, and surface roughness gauges. Every batch undergoes chemical composition checks, dimensional verification, and visual inspections per ISO 9001 protocols. Our QA team documents all results, and non-conforming parts are immediately quarantined. This end-to-end control ensures your CNC machined bike parts meet exact specifications—consistently and reliably.

Pricing depends on multiple factors: material type (e.g., 6061 vs. 7075 aluminum), tolerance tightness (±0.01mm costs more than ±0.1mm), part size, required surface finish, and order volume. Because we work directly with our own factories—not middlemen—we eliminate markup layers and provide real-time, transparent quotes based on your drawings. Just share your specs, and we’ll deliver a competitive offer within 24 hours.

All our pricing is built on a foundation of high quality—never compromised for cost. That said, larger order quantities reduce per-unit machining setup and handling costs, allowing us to pass savings to you. We also optimize toolpaths and material usage during production planning. If you’re comparing quotes, ask for like-for-like specs; with identical quality, HULK Metal consistently offers more competitive rates due to our integrated factory resources.

Minimum Order Quantity varies by part complexity, material, and size. A simple aluminum clamp might have an MOQ of 100 pieces, while a forged-and-machined crank arm could start at 500. To give you an accurate number, send us your 2D/3D drawings—we’ll sign an NDA first—and our engineers will assess manufacturability and quote both MOQ and lead time within one business day.

Standard lead time is typically 30 days from drawing approval, though complex or large-volume orders may take up to 45 days. Once tooling and fixtures are ready, our production lines run efficiently with minimal downtime. For urgent needs, we offer expedited scheduling. We always confirm realistic timelines upfront and keep you updated weekly—so you can plan your assembly or inventory with confidence.

We provide a full spectrum of finishes: anodizing (clear, black, colored), powder coating, passivation, bead blasting, polishing, galvanizing, and more. The best choice depends on your part’s material, function, and environment—for example, hard anodizing for pedal bodies, or powder coating for visible brackets. Our surface treatment partners are vetted and located near our machining factories, ensuring fast turnaround and consistent quality.

We’ve successfully delivered CNC machined bike parts to clients in over 50 countries—including Germany, the U.S., Canada, Brazil, Australia, South Africa, Japan, and across Southeast Asia. Our logistics team handles all export documentation, customs clearance, and carrier coordination via sea, air, or land. No matter your location, we ensure secure, trackable, and on-time delivery to your door or port.

We machine everything from tiny derailleur pivots (under 10mm) to large e-bike motor mounts (over 300mm). Feasibility depends on material, wall thickness, feature complexity, and required tolerances. Send us your 2D or 3D CAD files—we’ll sign an NDA—and our technical team will evaluate whether it fits our equipment capabilities (including 5-axis machines with large work envelopes) and advise on any design optimizations.

We accept T/T (bank transfer), irrevocable L/C at sight, and PayPal for samples. For delivery terms, we work with EXW, FOB (Shanghai/Ningbo), CIF, and DDP—whichever suits your import process best. If you have specific commercial requirements, just let us know during quoting; we’re flexible and experienced in international trade compliance to make transactions smooth and secure.

HULK Metal is not a trading company—we’re a professional CNC bike parts service provider with deep access to a network of ISO 9001-certified factories. We manage the entire process: engineering review, procurement, production, QA, and logistics. Our in-house team includes technical, sales, and supply chain specialists who ensure seamless execution from drawing to delivery—giving you the reliability of a manufacturer with the agility of a dedicated partner.

Absolutely. After finalizing tooling and programming, we produce a pre-production sample for your approval. This prototype undergoes the same quality checks as mass-produced parts and is shipped for your functional and dimensional validation. Only after you confirm the sample meets all requirements do we begin full production—ensuring zero surprises and perfect alignment with your expectations.

A: You can get a quote in a shorter time by providing the following information at once:

1. 2D and 3D drawings of the Bicycle Part Machining. If neither is available, samples can be provided.

2. Quantity.

3. Delivery Terms.

4. Material, surface treatment, tolerance, and weight. If no 3D drawing is available, please provide the following information:

At HULK Metal, quality isn’t an afterthought—it’s engineered into every step of the process. We go beyond standard machining to deliver bicycle components that meet the demanding expectations of global brands. Here’s how we consistently achieve superior results.

Our technical team doesn’t just read drawings—they interpret intent. With years of experience in bicycle part machining, they anticipate functional requirements, assembly constraints, and performance demands. This deep understanding allows us to recommend smarter material choices, tighter tolerances where needed, and cost-saving design tweaks—ensuring the final product aligns perfectly with your vision and application.

We’ve built a tightly integrated supply chain spanning certified metal suppliers, in-house machining factories, surface treatment partners, and logistics providers. This vertical coordination eliminates handoff gaps, reduces lead time variability, and ensures every input—from aluminum billet to packaging foam—is traceable, consistent, and optimized for bicycle-specific performance and durability.

We source raw materials like 6061-T6 or 7075 aluminum and stainless steel directly from long-term partner mills that provide mill test reports (MTRs). Every incoming batch undergoes chemical composition analysis and mechanical testing before entering production. This proactive screening prevents substandard material from ever reaching the CNC floor—laying the foundation for reliable, high-integrity machined parts.

Our factories enforce disciplined production protocols: tool wear is monitored hourly, machine calibration is performed weekly, and operators follow standardized work instructions. Multi-axis CNC programs are validated through first-article inspections. This rigorous control ensures dimensional stability across thousands of units—even for complex geometries like hollow cranks or integrated brake mounts—minimizing variation and maximizing repeatability.

Every finished part undergoes multi-stage inspection: CMM for critical dimensions, visual checks for surface defects, hardness tests, thread verification, and torque validation where applicable. Inspection data is recorded and shared upon request. Only parts meeting 100% of your specifications advance to packaging—guaranteeing zero-defect delivery to your assembly line or warehouse.

We customize packaging to protect your parts in transit—using anti-rust paper, foam inserts, individual boxing, or reinforced cartons based on part geometry and fragility. All shipments include clear labeling, packing lists, and real-time tracking. This attention to detail prevents damage during ocean or air freight, ensuring your CNC machined bike parts arrive in perfect condition.

Quality assurance doesn’t end at delivery. Once you receive your order, you can verify both quantity and quality. If any part has a defect or doesn’t match your specs, we offer immediate returns, exchanges, or restocking—at no extra cost. Our responsive support team resolves issues within 24 hours, because your trust is our most valuable asset.

At HULK Metal, quality control is embedded in every stage of bicycle part machining. We conduct rigorous dimensional, surface, mechanical, and material inspections using calibrated instruments and ISO 9001 protocols. Pre-shipment checks verify quantity, packaging, and conformity to your drawings. Custom inspection plans are available for mission-critical components. All data is documented and traceable—ensuring every CNC machined bike part meets your exact specifications before it leaves our factory.

We use CMMs, optical comparators, and precision gauges to verify critical dimensions, tolerances, and geometric relationships against your drawings—ensuring perfect fit during assembly and reliable performance under real-world riding conditions.

For high-risk or safety-critical parts like brake levers or crank arms, we develop tailored inspection protocols—including fatigue testing, salt spray trials, or third-party certification—based on your specific application and regulatory requirements.

Before dispatch, a final audit confirms packaging integrity, labeling accuracy, documentation completeness, and compliance with your purchase order—giving you confidence that the shipment is ready for seamless receipt and use.

Trained inspectors examine every part under controlled lighting for scratches, pits, burrs, or coating defects. Surface roughness is measured with profilometers to meet specified Ra values—critical for aesthetics and function.

Every raw material batch undergoes spectrographic analysis to verify chemical composition. Mill test reports are cross-checked, and samples are tested for grain structure and impurities—guaranteeing material integrity before machining begins.

Hardness testing (Rockwell, Brinell), tensile strength checks, and torque validation ensure parts perform as expected under load. These tests confirm that heat treatment or material selection aligns with your functional requirements and safety standards.

We perform 100% piece-count verification against your order. Packing lists are double-checked to prevent shortages or overages—ensuring you receive exactly what you paid for, every time.

HULK Metal partners with ISO 9001-certified factories in China that specialize in high-precision bicycle part machining. Our integrated production ecosystem includes advanced CNC machining centers, dedicated surface treatment lines, and a fully equipped quality control center. This vertical setup ensures tight process control, rapid iteration, and consistent output—whether you’re producing lightweight aluminum cranks or stainless steel brake components. Every factory adheres to strict operational standards, enabling us to deliver CNC machined bike parts that meet global performance and reliability expectations.

Our CNC machining factories are equipped with a mix of 3-axis, 4-axis, and 5-axis machining centers from leading brands, capable of handling complex geometries required for modern bicycle components. These machines run 24/7 under climate-controlled conditions to minimize thermal drift and maintain micron-level accuracy. Skilled operators and process engineers monitor tool wear, spindle load, and cycle consistency in real time. The shop floor is organized for lean production—grouping similar parts to reduce setup time while ensuring traceability through batch numbering. This infrastructure allows us to produce everything from high-volume sprockets to low-run custom adapters with the same commitment to precision, surface finish, and on-time delivery.

Our quality control center is staffed by certified inspectors and outfitted with industry-grade equipment—including coordinate measuring machines (CMM), optical comparators, spectrometers, hardness testers, surface roughness gauges, and salt spray chambers. Every incoming material batch, first-article sample, and final production lot undergoes documented inspection per your specifications and ISO 9001 requirements. Results are stored digitally for full traceability, and non-conforming items trigger immediate corrective action. This rigorous, data-driven approach ensures that only parts meeting 100% of your dimensional, mechanical, and visual criteria leave our facility—giving you confidence in every shipment of CNC machined bike parts.

Surface finishing is handled by specialized partner workshops located within our supply chain network, ensuring seamless handoff and consistent quality. These facilities offer anodizing (Type II and hard coat), powder coating, passivation, bead blasting, polishing, and more—all calibrated for bicycle-specific materials like 6061 and 7075 aluminum or stainless steel. Each line follows standardized parameters for bath chemistry, curing temperature, and coating thickness, with in-process checks to prevent color mismatch or adhesion failure. Because we manage these relationships directly, we can guarantee lead times, match RAL/Pantone colors accurately, and apply finishes that enhance both durability and brand aesthetics without compromising dimensional tolerances.

Choosing HULK Metal means partnering with a reliable, ISO 9001-certified source for high-precision CNC machined bike parts. We offer a complete OEM solution—from engineering review to global delivery—with strict quality control, competitive pricing, and faster turnaround than most China suppliers. Our integrated factory network, technical expertise, and responsive service save you time, reduce risk, and ensure every component performs as expected in real-world cycling applications.

HULK Metal manages your entire bicycle part machining project under one roof—no coordination headaches or third-party gaps. From initial drawing review and DFM feedback to raw material sourcing, multi-axis CNC production, surface finishing, packaging, and international shipping, our team handles every detail. This end-to-end ownership ensures seamless communication, consistent quality, and accountability at every stage. Whether you need a single prototype or monthly production runs, we act as your extended manufacturing arm, delivering fully finished, ready-to-assemble components that meet your exact functional and commercial requirements—on time, every time.

Because we work directly with our own network of factories—not brokers or resellers—we remove unnecessary markups while maintaining premium quality. Our scale allows bulk purchasing of aluminum and steel at better rates, and our optimized CNC programming reduces cycle time without sacrificing precision. We pass these efficiencies to you: for the same material, tolerance, and finish, HULK Metal consistently offers more competitive pricing than typical Chinese suppliers. And since we prevent defects through rigorous QA, you avoid hidden costs like scrap, rework, or production downtime—making our solution truly lower total cost.

All our CNC machined bike parts are produced in ISO 9001-certified factories and can comply with international standards such as ISO 4210 (bicycle safety), EN 14764/14766 (road/mountain bikes), and ASTM material specs. We provide full documentation—including material test reports, inspection certificates, and process records—upon request. Our quality system ensures traceability from raw billet to finished part, giving you confidence for audits, certifications, or regulatory submissions. This commitment to standardized production is why global brands trust HULK Metal for components that must perform safely under demanding conditions.

Speed doesn’t mean cutting corners—it means smarter planning. Thanks to our in-house technical team, pre-qualified tooling partners, and buffer stock of common alloys, we eliminate typical delays in quoting, setup, and material procurement. Once your drawings are approved, production starts within 48 hours. Our factories run efficient shift patterns and prioritize bicycle projects due to long-standing volume relationships. The result? Reliable lead times of 30 days (often less for repeat orders)—so you can launch new models, restock inventory, or respond to market demand without waiting weeks for parts.

Sourcing from overseas shouldn’t drain your resources. With HULK Metal, you get a single point of contact who speaks your language, understands bicycle engineering, and coordinates everything behind the scenes. No chasing multiple vendors, decoding vague replies, or managing quality surprises. Our transparent process—from real-time quoting to shipment tracking—frees your team to focus on design, marketing, or sales. We handle the complexity so you don’t have to, turning what’s often a stressful procurement task into a smooth, predictable partnership.

Explore our collection of in-depth articles on bicycle part machining—covering design tips for CNC bike components, material selection guides, surface finish comparisons, and case studies on high-performance parts like cranks, hubs, and brake mounts. Whether you're an engineer, product designer, or procurement specialist, these resources offer practical insights to help you optimize quality, cost, and lead time when sourcing precision-machined bicycle parts from China.

Beyond bicycle components, HULK Metal produces a wide range of precision CNC machined metal parts—including automotive brackets, drone frames, industrial pump housings, robotics joints, medical device fittings, and custom hardware. Our expertise spans aluminum, stainless steel, alloy steel, and brass across industries requiring tight tolerances, complex geometries, and reliable surface finishes. If it can be machined, we’ve likely made it—on time, to spec, and at scale.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

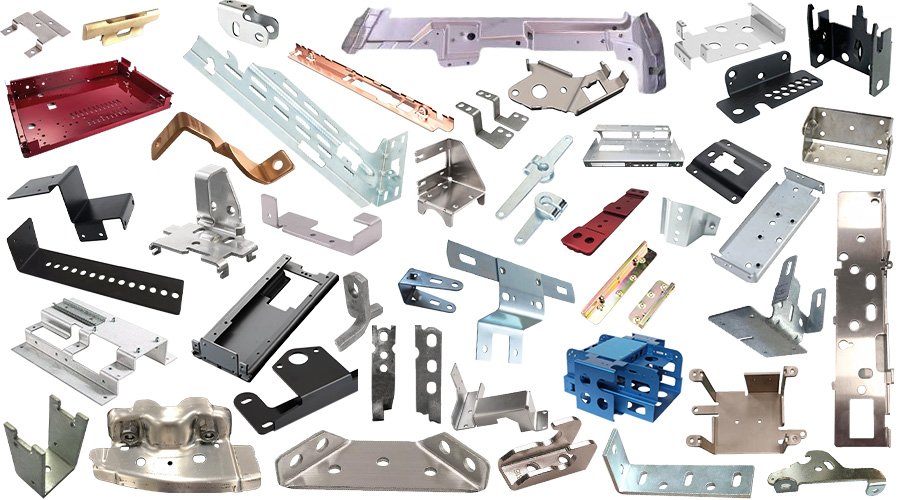

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Precision forging is a near-net-shape manufacturing process that creates high-strength components with superior mechanical properties. At HULK Metal, our OEM services integrate advanced hot and cold die forging with precision CNC machining.

HULK Metal provides a comprehensive OEM solution for high-precision forged steel parts, integrating advanced hot and cold forging factories with elite 5-axis CNC machining.

Description HULK Metal provides a vertically integrated manufacturing solution for Motorcycle Forged Parts, specializing in high-strength components like crankshafts, connecting rods, and triple clamps.

Mining environments demand components with exceptional wear resistance. HULK Metal manufactures custom mining forged parts using premium carbon and alloy steels.

ISO 9001-certified metal forging factory. The technical team supports every phase—from print review to process optimization. Faster turnaround without sacrificing accuracy. Full QA with returns/rework guarantee.

Forged gear blanks provide higher strength, better grain flow, and improved fatigue resistance compared with cut gears.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

HULK Metal provides high-capacity OEM manufacturing for commercial-grade Chin Up Bars, utilizing over 50 automated welding stations and high-speed fiber laser cutting. Our ISO 9001-certified factory ensures every component meets a 99.8% precision rate, delivering structural safety and aesthetic consistency.

Our heavy-duty Barbell Holder Attachment is engineered for seamless integration into commercial power racks and home gym systems. Utilizing high-grade steel and precision laser cutting, we provide comprehensive OEM services that transform your technical drawings into market-ready components.

HULK Metal delivers industrial-grade Weight Plate Tree manufacturing, transforming complex technical drawings into durable gym hardware. Our Bar and Weight Plate Tree OEM services prioritize structural integrity through advanced metalworking.

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU