We measure every critical tolerance with CMMs, callipers, and go/no-go gauges. Holes, bends, weld seams—if it’s on your drawing, we check it. No “eyeballing.” Only hard data ensures a perfect fit during final assembly.

HULK Metal is your go-to fabricator for high-performance gym equipment components. With ISO 9001-certified factories and deep expertise in metal forming, we turn your drawings into durable, precise parts—fast and affordably. From laser-cut plates to forged safety arms, we handle every stage: material sourcing, production, QC, and global delivery. No design? No problem. We build what you specify. Let’s get your next batch moving—smoother, stronger, and smarter than before.

1.ISO 9001 certified factory

2.Professional technical team to provide support

3.Finalize your order faster

4.Perfect quality assurance service.

5.Finalize your order at a lower price.

HULK Metal crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, forging—all under one roof. Your drawings drive production; our team ensures every part meets spec, ships on time, and costs less than you’d expect. No fluff, no delays—just stronger metal parts, made right.

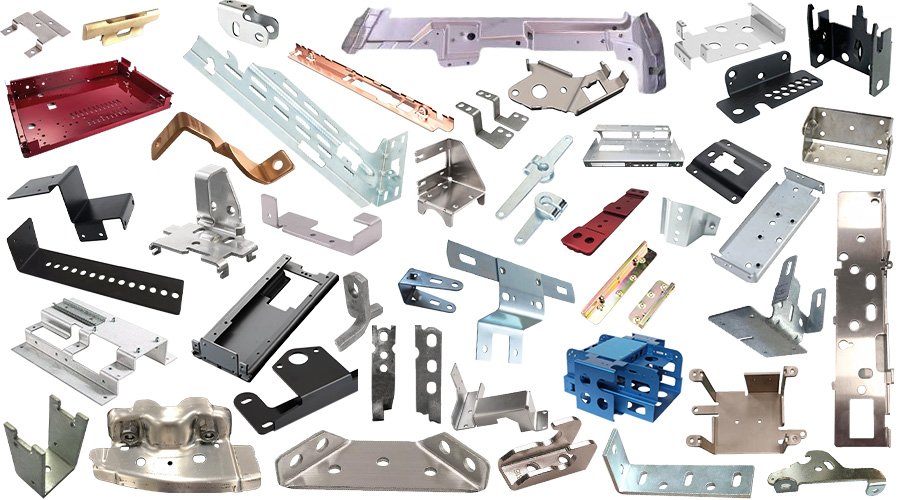

Our Fabricated Gym Equipment Components OEM Services turn your technical drawings into rugged, ready-to-assemble parts—no guesswork, no middlemen. We work with sheet metal, pipes, and structural profiles in steel, iron, stainless, or aluminum. Whether it’s J-cups, bench frames, or cable machine brackets, we stamp, weld, forge, or machine them to spec. Surface finishes? Powder coat, anodize, sandblast—you name it. Every batch gets full QC, global shipping, and lifetime support.

Name | Fabricated Gym Equipment Components OEM Services |

Manufacturing Methods | Manufacturing According to Drawings |

Materials Size | Sheet Metal, Profiles, Strips, Pipes |

Raw Materials | Iron, Steel, Stainless Steel,and Aluminum. |

Process | Stamping:Blanking, Bending, Shearing, Deep Drawing, Expanding, Spinning, Straightening. Welding, Cutting Casting: Sand Casting, Investment Casting, Lost Foam Casting Forging: Hot Die Forging |

Types | Steel Frames & Main Structures, Laser-Cut Adjustment Plates, J-Cups、Safety Arms & Spotter Arms Components, Cable Machine Structural Parts, Bench Components, Barbell Rack Components, Foot Platforms & Stamped Plates. |

Surface Treatment | Powder Coating, Anodized, Sandblasting, Raw Black / Customized |

Test Content & Data | 1. Chemical Composition; 2. Mechanical Properties; 3. Inspection of appearance, size, shape, and position tolerance; 4. Surface Quality; |

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

Delivery Method | Sea / Air / Land |

Quality Assurance | Life Long |

From steel frames to laser-cut adjustment plates, HULK Metal handles every Gym Equipment Component with factory-direct precision. We don’t just make parts—we manage the whole chain: material sourcing, multi-process fabrication, strict inspection, and global logistics. Whether you need 500 or 50,000 units, our technical team locks in your specs, tightens lead times, and cuts costs without cutting corners. Stronger metal. Smarter production. Zero drama.

Gym Equipment Components are the backbone of every strength machine, rack, and functional trainer—the hidden heroes that hold up under daily abuse and keep users safe. At HULK Metal, we don’t design workouts; we build what makes them possible. Think heavy-gauge steel frames that won’t flex, laser-cut adjustment plates with zero burrs, forged J-cups that take repeated drops without deformation. Our OEM service means you bring the blueprint—we handle the rest: material selection, process engineering, precision fabrication, and surface finishing that lasts. We’re not a brand; we’re your behind-the-scenes partner with factories that run tighter tolerances, move faster on tooling, and cost less than typical suppliers. Whether you’re outfitting a boutique gym or scaling global equipment lines, we turn metal into muscle—reliably, repeatedly, and without surprises.

We turn your drawings into gym-ready metal parts through a tightly controlled, step-by-step process—no shortcuts, no guesswork. From mold design to final inspection, every stage is handled in-house by specialists who’ve done this thousands of times. You get consistency, speed, and cost control—because we own the whole line.

Before cutting any metal, we sit down with your specs and ask: Should this be stamped? Laser-cut? Forged? Cast? Each method affects strength, cost, and lead time. A safety arm might need hot die forging for impact resistance, while an adjustment plate screams for precision laser cutting. We match process to purpose—so you don’t overpay for unnecessary steps or under-build for heavy use. Smart choices upfront save headaches (and money) downstream.

If your part needs stamping or casting, we don’t farm out tooling—our in-house team builds and tests every mold. We simulate stress points, tweak draft angles, and run pilot batches before full production. Found a burr? Adjusted. Flash on edges? Fixed. This isn’t “hope it works”—it’s precision engineering with real-world validation. Your first production run comes out clean because we debugged everything beforehand—quietly, efficiently, without billing you for trial and error.

We don’t grab whatever’s cheapest off the shelf. Our procurement team pulls certified mill test reports, checks grain structure, verifies alloy composition—even for standard steel grades. Every coil, billet, or tube gets logged, sampled, and tested before it hits the floor. No mystery metals. No “close enough” substitutions. If your spec calls for Q345B structural steel, that’s exactly what goes into your frames—traceable, tested, tough as promised.

Once tooling and materials are locked in, we ramp up with zero drama. Stamping presses run 24/6 with inline sensors catching dimensional drift. Weld cells use jigs so every joint lands in the same spot. CNC machines auto-load blanks and hold ±0.05mm tolerances all day. We scale smoothly—whether you need 500 or 50,000 units—because our lines are tooled for repetition, not improvisation. Predictable output. Consistent quality. No surprises.

Every batch gets hit with calipers, gauges, hardness testers, and vision systems—not just at the end, but mid-process. We check hole spacing on laser-cut plates, weld penetration on frames, surface roughness after grinding. Miss a spec? The line stops. Nothing ships until it passes—and we document every result. You’ll get inspection reports with your shipment, so you know exactly what landed in your warehouse.

We don’t just toss parts in a box. Heavy frames? Crated with corner braces. Small brackets? Individually bagged to prevent scratching. Export-bound? Treated wood, moisture barriers, custom labels. We’ve shipped to humid ports, dusty warehouses, and high-security distribution centers—and learned how to pack for each. Need barcodes? QR tracking? Special labeling? Just say the word. Your logistics team will thank you when everything arrives intact and easy to sort.

Delivery isn’t the finish line—it’s the starting gate for our support. Count wrong? We补货 yesterday. Surface finish off-spec? We’ll remake and airfreight replacements. Got assembly questions? Our engineers jump on a call. We don’t vanish after payment clears. You’re stuck with the parts—so we stick with you until they’re installed, working, and satisfying your end-users. That’s how partnerships last.

We build the bones of every serious gym—from squat racks to cable machines. Each category is engineered for abuse, finished for durability, and produced with zero tolerance for weak links. Below are the core families we handle daily, with real-world examples and material specs you can bank on.

Category | Component Examples | Description |

Steel Frames & Main Structures | Power rack uprights, Smith machine bases, functional trainer towers, leg press frames, lat pulldown columns | These aren’t just welded tubes—they’re load-bearing skeletons built to survive commercial abuse. We use high-tensile steel profiles, precision notched and MIG/TIG welded for rigidity. Every joint is gusseted or reinforced where stress concentrates. Laser-cut mounting holes align perfectly across batches. Surface prep includes grit blasting before powder coat, so paint doesn’t flake under chalk and sweat. Whether it’s a boutique rack or a CrossFit rig, we make frames that don’t flex, creak, or fail—year after year. |

Laser-Cut Adjustment Plates | Bench backrest plates, cable crossover height selectors, dip station position stops, leg extension angle guides, preacher curl pad mounts | Precision is everything here—one misaligned hole ruins the user experience. We laser-cut these from 6–12mm steel plate with ±0.1mm accuracy, then deburr every edge by hand or automated brush. Holes are chamfered to prevent cable or pin wear. Many include engraved numbering or icons for quick ID. Powder coating or zinc plating protects against finger oils and cleaning chemicals. These small parts take big abuse—we make sure they outlast the machines they control. |

J-Cups, Safety Arms & Spotter Arms | Olympic barbell J-hooks, telescopic safeties, flip-up spotter arms, monolift brackets, band peg integrated arms | These catch heavy bars—sometimes dropped in panic. We forge or CNC-machine them from hardened alloy steel, then heat-treat critical zones like hook curves and pivot pins. Surfaces are ground smooth to avoid bar knurl damage. Telescopic arms glide on precision bushings; flip-up mechanisms use grease-packed bearings. Every unit is load-tested beyond max spec. No plastic liners, no stamped sheet metal fakes—just solid, silent, reliable protection that gym owners trust with their clients’ safety. |

Cable Machine Structural Parts | Pulley mounting plates, guide rod housings, weight stack separators, swivel joint brackets, top frame crossmembers | Hidden but vital—these parts endure constant tension, friction, and cyclic loading. We machine bearing seats to tight tolerances so pulleys spin true. Weight stack separators are sand-cast ductile iron for impact resistance. All edges are radiused to prevent cable fraying. Zinc-plated or anodized finishes resist corrosion from sweat drips and cleaning sprays. Designed for silent operation and minimal maintenance, these components keep machines running smoothly through thousands of daily reps—without squeaks, binds, or failures. |

Barbell Rack & Bench Components | Plate storage horns, upright stabilizer feet, bench leg braces, knurled grip handles, adjustable seat slide rails | Small doesn’t mean simple. Storage horns are bent and ribbed to prevent plate roll-off. Bench legs get triangulated bracing to kill wobble during heavy presses. Slide rails are ground flat and hard-chrome plated for buttery movement. Knurling? We match depth and pattern to your spec—aggressive for grip, gentle on palms. Everything bolts together with zero slop. These parts turn good equipment into great equipment—the kind users notice for its rock-solid feel and smooth function. |

We keep it practical—no over-finishing that gets stripped or painted over by your assembly line. Need raw steel with light oil coating to prevent flash rust during shipping? Done. Want parts ready for your own powder coat or e-coat system? We’ll deliver clean, grit-blasted, perfectly prepped surfaces. Or, let us handle the full finish: durable powder coating in any RAL code, zinc plating for corrosion resistance, hard anodizing for aluminum components, or textured sandblast for grip zones. Every treatment is matched to the part’s material, function, and environment—so it lasts longer and performs better, whether it’s mounted indoors or exposed to garage-gym humidity.

When you’re sourcing Fabricated Gym Equipment Components from China, not all factories are built the same. HULK Metal stands out because we’ve fine-tuned every link in the chain—so you don’t waste time chasing fixes or delays. Here’s what actually matters when picking a partner who won’t let you down.

Our engineers aren’t just order-takers—they read between the lines of your drawings. If a bend radius looks risky or a weld zone might crack under load, they’ll flag it before metal ever hits the press. They’ve handled weird geometries, tight tolerances, and last-minute spec changes for clients across 50+ countries. That means fewer revisions, faster approvals, and parts that fit right the first time—no back-and-forth, no finger-pointing.

We don’t rent bench space—we own and operate multiple dedicated factories with overlapping capabilities. Stamping? Check. Laser cutting at scale? Check. Simultaneous forging runs? Also check. This lets us absorb big orders without bottlenecks and still turn small batches fast. No subcontracting surprises. No “we’re waiting on another shop.” Your project moves through our system like clockwork—whether it’s 500 safety arms or 50,000 adjustment plates.

ISO 9001 isn’t a wall decoration here—it’s how we run every shift. Every part gets dimensional checks, surface scans, hardness tests, and visual inspections before boxing. We track every batch back to its raw material coil or billet. Missed a tolerance? We catch it. Surface scratch? We reject it. You get consistency—gym after gym, shipment after shipment—because we treat every order like it’s going into our own facility.

We’ve locked in long-term deals with mills and alloy suppliers—so when steel prices swing, your quote doesn’t. Need stainless today and aluminum next month? We’ve got both in stock. Fasteners, bushings, rubber caps? We source them too. No scrambling for secondary parts. No delays from “waiting on materials.” Just one partner, one PO, one predictable timeline—even when global supply chains hiccup.

From the moment you send a drawing, you get a single point of contact—not a rotating cast of reps. They’ll walk you through tooling options, surface finish trade-offs, packaging specs—whatever you need. Got a customs snafu? We handle documentation. Need photos mid-production? We’ll send them. Post-delivery issue? We jump on it—replacements, credits, reworks. We’re not done until your warehouse is happy.

LC, T/T, DP—we work with what your finance team prefers. Incoterms? FOB, CIF, DDP—name your comfort zone. Need staggered payments tied to production milestones? We’ll draft it. No rigid templates, no “our way or the highway.” We adapt to your cash flow and risk tolerance because smooth transactions mean smoother partnerships—and repeat business.

We’ve shipped Gym Equipment Components to warehouses in Germany, gyms in Texas, distributors in Dubai, and pop-up studios in Jakarta. Sea, air, rail—we optimize cost vs speed based on your deadline. Crate it? Palletize it? Individually wrap it? Done. We handle export docs, HS codes, port fees—you just tell us where and when. No hidden freight surprises. No “lost in transit” drama.

If a part arrives bent, scratched, or short-counted, we fix it—fast. No arguments, no runaround. We’ll ship replacements overnight or credit your account same week. Our QA doesn’t stop at our dock—it follows your shipment. Take your time inspecting. Find an issue? Snap a photo, send it over. We make it right. Lifetime. Because your reputation depends on flawless gear—and so does ours.

We don’t wing it—every part moves through a documented QC flow backed by calibrated tools and trained inspectors. Hardness testers, CMMs, surface roughness gauges, salt spray chambers—we’ve got them all in-house. Every batch gets material certs, dimensional reports, and visual sign-offs before boxing. If your drawing calls for ±0.1mm, we hit it—or we scrap it. No exceptions. And because we control the whole chain—from raw steel to final packaging—there’s no finger-pointing between subcontractors. Just one team accountable for perfection.

It’s not one-size-fits-all—price swings with material thickness, tolerance tightness, surface finish, and order volume. A laser-cut plate with loose specs? Cheap. A forged safety arm needing heat treat and hard chrome? Higher. But here’s the kicker: we own the factories, so no middleman markup. Send us your drawing + quantity, and we’ll quote same-day with line-item breakdowns—material, process, finish, freight. No smoke, no mirrors. Just real numbers based on how it’s actually made.

Simple—bigger batches unlock better rates. Tooling costs spread thinner. Material buys get bulk discounts. Machines run longer without changeovers. We pass those savings straight to you. Also, loosen tolerances where function allows—±0.5mm instead of ±0.1mm can slash machining time. Skip secondary finishes if you’re coating in-house. Want the lowest possible cost without sacrificing durability? Tell us your “must-haves” vs. “nice-to-haves.” We’ll engineer the smartest, leanest version that still crushes in the gym.

Depends on the beast. Small laser-cut brackets? Could be as low as 200 pcs. Complex sand-cast housings needing custom tooling? Might start at 1,000. We don’t enforce arbitrary minimums—we calculate break-even based on setup time, material yield, and tool amortization. Send us your 2D/3D file (we’ll sign NDA immediately), and we’ll tell you the sweet spot: lowest quantity that keeps unit cost sane. Need prototypes first? We’ll do that too—often at near-production pricing.

Typically, 30 days from PO + deposit—but we’ve shipped complex orders in 18 when schedules demanded it. First week: material in, tooling confirmed. Next two: production + inline QC. Final week: finishing, packing, docs ready. Rush jobs? We’ll pull weekend shifts or airfreight sub-assemblies. Big orders? We stage deliveries—ship half while finishing the rest. Delays? You’ll hear from us before your calendar does. We treat deadlines like gym PRs—meant to be hit, not hoped for.

We partner with top-tier coating shops—powder coat (any color, texture, or gloss level), zinc plating (clear, yellow, black), anodizing (Type II or III for aluminum), e-coat, or raw with rust inhibitor. Don’t know which finish suits your use case? Tell us: indoor commercial? Outdoor bootcamp? High-sweat zone? We’ll recommend the most durable, cost-effective option. All finishes include pre-treatment—degreasing, phosphating, grit blasting—so adhesion lasts. No peeling. No premature rust. Just tough surfaces that look good and hold up.

Last year alone: Germany, USA, UAE, Australia, Brazil, South Korea, Saudi Arabia, Canada, UK, Thailand—over 50 total. We handle FOB Ningbo, CIF Rotterdam, DDP Los Angeles—whatever Incoterm you prefer. Customs forms? HS codes? Fumigation certs for wood crates? Done. Freight forwarders? We’ve got trusted partners for sea, air, even rail to Europe. Tracking updates? Sent weekly, or daily if you’re anxious. Distance doesn’t complicate things—we’ve turned global shipping into a boring, predictable part of the process.

From tiny laser-cut washers (5mm) to 6-meter welded frames—if your drawing fits our machine envelopes, we’ll make it. Our laser cutters handle sheets up to 3m x 1.5m. Press brakes bend 4m lengths. Foundry pours castings up to 500kg. For oversized assemblies? We build in sections with precision dowel pins for perfect field alignment. Send your 2D/3D file (NDA-protected), and we’ll confirm feasibility within 24 hours—including suggestions to simplify fabrication or cut cost without losing function.

Speed up quoting by sending:

(1) 2D drawings with critical dims/tolerances—or 3D STEP files;

(2) Material spec (e.g., Q235B, 6061-T6);

(3) Surface finish preference;

(4) Quantity + target delivery date;

(5) Packaging needs (bulk, individual, crated).

No drawing? Send a sample—we’ll reverse-engineer it. Missing specs? Our engineers will fill gaps and send options for approval. More detail upfront = faster, more accurate quote. We’ll even mark up your drawing with manufacturability tips—free of charge.

Q10: What payment methods and delivery terms do you support?

LC at sight? T/T 30% deposit, 70% before shipment? DP? We’ve done them all. Prefer milestone payments tied to production stages? Draft it—we’ll sign. Incoterms? FOB, CIF, DAP, DDP—name your risk threshold. Need us to handle insurance or customs clearance? Added easily. We’re flexible because rigid payment terms kill good partnerships. Finance team has special requirements? Loop them in—we’ll find a structure that works for both sides.

Q11: Is HULK Metal a factory, manufacturer, or trading company of Fabricated Gym Equipment Components?

We’re a hybrid—factory-backed supplier with direct control over production, but structured like a pro OEM partner. We don’t just own presses and welders—we have procurement specialists, QA engineers, logistics coordinators, and bilingual project managers under one roof. No trading fluff. No subcontracting roulette. You get factory prices with enterprise-level service: technical reviews, material traceability, inspection reports, and global shipping handled seamlessly. Think of us as your in-house metal department—just located in China.

We don’t skim drawings—we study them like blueprints for battle tanks. Our engineers ask why before they start how. Is that flange for bolt-on accessories? Then we reinforce the weld zone. Is that hole for frequent pin adjustments? We deburr it twice. This depth of understanding means fewer misinterpretations, zero “that’s not what we meant” moments, and parts that perform exactly as your end-users expect—rugged, reliable, repeatable.

Our raw material suppliers aren’t random vendors—they’re vetted, long-term partners who reserve premium-grade coils and billets for us. That means consistent chemistry, tighter thickness tolerances, and no last-minute substitutions. Need AISI 1045 instead of generic mild steel? We’ve got it in stock. This supply chain control eliminates material-related defects before production even starts—so you get uniform strength, predictable machining behavior, and zero surprise failures down the line.

Every steel coil, aluminum extrusion, or cast blank gets logged, sampled, and tested before it touches a machine. We pull mill certs, verify hardness, check grain flow—even on “standard” orders. If a batch drifts outside spec, we reject it—no exceptions. This upfront diligence costs us more but saves you from field failures, returns, and brand damage. Better to catch a bad billet early than a broken barbell rack in a gym.

Our shop floor runs like a Swiss watch—calibrated machines, documented SOPs, trained operators who sign off at every station. Stamping dies are inspected hourly. Weld parameters are locked in and logged. CNC tools get replaced before they dull. We don’t chase speed at the cost of precision. If a part requires 3 passes to hold tolerance, we do 3 passes. No shortcuts. No “good enough.” Just disciplined, repeatable manufacturing that turns out identical parts—batch after batch.

We inspect like we’re building gear for our own gyms. Dimensional checks with CMMs. Surface scans for scratches or pits. Load tests on safety arms. Salt spray trials on coated parts. Every shipment includes a full report—traceable back to heat number and operator ID. Miss one spec? The whole batch gets quarantined. You won’t find surprises in your warehouse because we already caught them—and fixed them—on our dime.

We treat packaging like armor. Heavy frames? Bolted to custom skids with edge protectors. Small machined parts? Vacuum-sealed in VCI bags to stop rust during sea freight. Export crates? ISPM-15 certified, labeled with handling instructions in your language. We’ve shipped through monsoons, desert heat, and Arctic ports—and learned how to pack for each. Your parts arrive dent-free, dry, and ready to assemble—not dinged, corroded, or lost in transit chaos.

Delivery isn’t goodbye—it’s the start of our support. Open a crate and find a bent bracket? Snap a photo, email it, and we’ll airfreight replacements before you finish your coffee. Quantity short? We restocked on the same day. We don’t hide behind “final sale” clauses. Your reputation rides on flawless equipment—so we ride shotgun until every part is installed, working, and satisfying your customers. That’s real partnership.

Every Gym Equipment Component we ship passes through six layers of inspection—from raw material certs to final packaging audits. Our ISO 9001 system leaves nothing to chance. Dimensional accuracy, surface finish, mechanical strength—all verified with calibrated tools and documented reports. You get parts that fit, function, and endure—batch after batch, year after year.

We measure every critical tolerance with CMMs, callipers, and go/no-go gauges. Holes, bends, weld seams—if it’s on your drawing, we check it. No “eyeballing.” Only hard data ensures a perfect fit during final assembly.

Custom checks? Done. Engraving legibility? Verified. Thread compatibility? Tested with actual bolts. Special requests don’t get sidelined—they get added to our QC checklist. Your specs rule. We just enforce them.

Final audit before boxing: quantity confirmed, packaging secure, labels accurate. We photograph random units and send you proof. Nothing leaves our dock unless it matches your PO—down to the last washer and barcode.

Before fabrication, we verify alloy composition via spectrometer and cross-check mill certs. No mystery metals. No substitutions. You specified Q345B? That’s what’s in your parts—traceable, tested, and tough as promised.

We count twice—once during packing, again before truck loading. Short shipments cost you time and trust. So we weigh bulk orders, scan barcoded kits, and tally manually when needed. You get exactly what you paid for.

Tensile strength, hardness, impact resistance—we test samples from every heat lot. Safety arms? Load-tested beyond max spec. Frames? Torque-checked at joint points. If it bears weight or stress, we verify it can handle more.

Trained inspectors scan every part under bright light for scratches, pits, or coating flaws. We reject anything that risks corrosion or user discomfort. Smooth edges, uniform finishes, zero handling marks—that’s the standard, not the exception.

HULK Metal doesn’t outsource—we own and operate specialized factories for every stage: laser cutting, stamping, forging, welding, CNC, and surface finishing. Each shop is tooled for gym-grade toughness, staffed by veteran operators, and managed under one roof. That means tighter control, faster turnarounds, and costs that beat scattered suppliers. Your parts move seamlessly from raw steel to boxed shipment—no handoffs, no delays, no excuses.

From boring precise bearing bores to milling complex cam profiles, our 40+ CNC centers handle it all—3-axis, 4-axis, even 5-axis for contoured safety arm curves. Tools are preset offline; in-process probes verify dimensions mid-cut. Coolant systems keep temps stable for tight-tolerance work. Aluminum, steel, stainless—we machine them all with surface finishes down to Ra 0.8µm. Need custom threads, counterbores, or engraved logos? Done in one setup. No secondary shops. No misaligned features. Just machined perfection, direct from our floor to yours.

Safety arms, barbell hooks, pivot pins—anything that catches heavy iron gets forged here. We use 2,500-ton hydraulic presses and closed-die hot forging to align grain structure for maximum impact resistance. Parts then go through normalizing, quenching, and tempering cycles tailored to each alloy. Final machining hits bearing surfaces to H7 tolerance. No stamped sheet-metal fakes. No weak weld zones. Just solid, grain-flow-optimized metal that laughs at dropped bars and keeps protecting users—rep after rep, year after year.

We run sand casting and lost foam lines for complex, load-bearing shapes like pulley housings, weight stack guides, and base feet. Patterns are CNC-machined in-house; molten iron or aluminum pours under controlled atmospheres to minimize porosity. Every casting gets X-ray or ultrasonic checked for internal flaws. Post-cast, we grind parting lines smooth and heat-treat for uniform hardness. No brittle zones. No hidden voids. Just dense, vibration-dampening metal built to survive years of slamming weights and sweaty grips—without cracking or deforming.

This is where trust gets built—not promised. CMMs scan complex geometries. Spectrometers verify alloy mixes. Salt spray chambers torture-test coatings for 500+ hours. Load frames simulate 5-year abuse in 48 hours. Every batch gets digital reports—stored, searchable, shareable. Find an issue? Trace it back to the coil, shift, and operator. Our QC isn’t a gatekeeper—it’s your insurance policy. Sleep easy knowing every part shipped has already passed worse than your gym will ever throw at it.

We prep right—grit blasting to SA 2.5 profile, phosphating for adhesion, masking critical zones. Then finish smart: powder coat cured at 200°C for chip resistance, zinc plating with trivalent chromate for salt-spray survival, or hard anodizing for aluminum wear parts. Color matching? RAL, Pantone, or sample-based—nailed every time. No orange peel. No thin spots. Just durable, gym-ready finishes that look sharp under bright lights and hold up against chalk, sweat, and daily scrub-downs.

Our 8,000-ton press line runs 20+ progressive dies daily—churning out J-cups, bracket plates, and adjustment mechanisms with ±0.05mm repeatability. Dies are maintained weekly; sensors auto-reject off-spec parts. We stamp everything from 0.8mm shims to 12mm structural flanges in steel, stainless, or aluminum. No subcontracting. No “we’ll try.” Just high-speed, high-precision metal forming tuned for gym abuse—whether you need 500 or 500,000 units. Engineers on-site tweak clearances and springback compensation in real time—so your first piece matches your thousandth.

This isn’t garage stick welding—it’s robotic MIG and precision TIG cells fixturing frames within ±0.2mm alignment. Jigs hold uprights, crossmembers, and gussets rock-solid while sensors monitor arc stability and penetration depth. Post-weld, we stress-relieve critical joints and magnaflux-test for micro-cracks. Grind marks? Only where specified. Warping? Compensated via pre-bend tooling. Whether it’s a compact rack or a 6-station rig, every weld is clean, strong, and dimensionally locked—ready for powder coat and punishing workouts.

Our fiber lasers slice 20mm steel and 30mm aluminum with kerf widths under 0.1mm—perfect for adjustment plates, logo panels, and intricate brackets. Nesting software maximizes material yield; automatic loaders keep beds fed 22 hrs/day. Edges come deburred inline—no secondary handling. Tolerances? Held to ±0.05mm across full sheets. Need micro-holes for pin detents or tapered slots for sliding mechanisms? We cut them clean, consistent, and ready to assemble—no filing, no fitting, no frustration.

Choose HULK Metal and skip the sourcing headaches. We deliver stronger parts, faster turnarounds, and lower costs—all backed by factory-direct control and lifetime QA. No middlemen. No mismatched tolerances. Just precision metal components built for real gyms, shipped globally, supported relentlessly. Your designs. Our discipline. Let’s build gear that doesn’t break—and partnerships that don’t bend.

We handle everything from raw steel to boxed shipment—no scrambling for welders, coaters, or freight forwarders. Send us your drawing, and we manage material sourcing, process engineering, multi-stage fabrication, inspection, packaging, and global logistics. Need help optimizing a design for manufacturability? Our engineers jump in—free of charge. Prototypes? Done in parallel with tooling. Revisions? Rolled in without restarting the clock. This isn’t piecemeal production—it’s seamless, single-source execution that turns your specs into shelf-ready parts without drama, delays, or hidden markups.

We cut cost without cutting corners—by owning the whole chain. Bulk material buys. In-house tooling. No broker fees. Multi-process factories under one roof eliminate transport markups and coordination delays. Want the lowest possible price? We’ll value-engineer your part: swap sand casting for stamping where strength allows, loosen non-critical tolerances, simplify finishes for in-house coating. Every suggestion comes with hard savings data—not vague promises. You get gym-tough parts at prices that let you compete—or profit more—without sacrificing an ounce of durability.

Every part we ship meets or exceeds ISO 9001, with full material traceability and inspection documentation. Need RoHS, REACH, or ASTM compliance? We’ve got certs on file. Exporting to EU or North America? We prep CE/FCC-ready technical files. Structural components? Load-tested beyond commercial gym ratings. Surface finishes? Salt-spray and abrasion-tested per industry norms. We don’t guess at standards—we bake them into every process. Your compliance team will love the paperwork. Your customers will love the reliability. And you’ll love not getting audited into panic mode.

You’re not handed off to a “customer service rep” who’s never seen a CNC machine. Your project manager is a production veteran who reads GD&T, understands heat treatment trade-offs, and tracks your order like it’s their own. Need photos mid-build? Sent same day. Customs holdup? We fix docs overnight. Parts arrive damaged? Replacements air-shipped before you finish the email. We don’t do scripted support—we do obsessive, human, fix-it-now partnership. Because your success isn’t a KPI for us—it’s the only metric that matters.

We cut the wait—no subcontractor delays, no material bottlenecks. Your drawing triggers an immediate production plan: tooling prepped, steel staged, machines booked. Prototypes? Done in parallel. Rush jobs? Weekend shifts activated. Average lead time: 30 days—but we’ve shipped complex orders in 18. Weekly updates, real-time photos, split shipments if needed. Speed isn’t a promise—it’s how we’re wired. Get gym-ready parts when you need them, not when factories feel like it.

Dive into real-world insights: how forged J-cups outlast stamped ones, why laser-cut plates reduce assembly headaches, what surface treatments survive sweaty gyms best. We break down material choices, tolerance trade-offs, and production hacks that save cost without sacrificing durability. Whether you’re scaling a fitness brand or upgrading commercial equipment, our articles give you the metal knowledge to spec smarter, source better, and avoid costly mistakes. No fluff. Just factory-floor truth.

Beyond frames and plates, we fabricate everything that moves, holds, or supports: urethane-coated dumbbell handles, pivot pins for functional trainers, rubber bumper feet, cable machine pulleys, Olympic bar collars, lat tower swivel joints, and knurled grip sleeves. Each part is built to match your system’s specs—material, finish, load rating. Need custom fasteners or wear-resistant bushings? Done. Think of us as your silent partner for every metal piece that turns good equipment into indestructible gear.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU