We use CMM, vernier calipers, and specialized gauges to measure all key dimensions. This ensures that jaws, handles, and components precisely match drawings and maintain stable performance.

Jaw Wire Puller is a special Wire Puller used for tensioning various cables, wires, and wire ropes. HULK Metal is its manufacturer. We have a variety of Jaw Wire Pullers to choose from. Welcome to consult us.

1. Available 1500 to 20000 LBS

2. ISO 9001 Certification

3. Suit For 1.9 mm to 45.7mm Various Cables, Wire Ropes

4. Factory Direct Sales

Jaw Wire Puller orders will undergo strict sampling inspections before leaving the factory to ensure that the order qualification rate can reach 99.99%. We provide QA services. You can purchase with confidence.

Our Jaw Wire Puller has two types of jaws to accommodate a wider variety of wires. Some types also have side panels to prevent the wire from slipping out from the side during tensioning. You can choose a more suitable one based on factors such as wire type, wire diameter, and usage scenario.

| Name | Come Along Clamp | ||||||

| Picture |  | ||||||

| Suit for | Copper Cable, Cover Cable,Bare Aluminum Cable, ACSR, ACSS, AAC, ABC, Bare Cu Cable, Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GTA - 050 - 060 | 5000.0 | 20.0 | 2.0 | 0.2 | 0.6 | 4.5 | 15.0 |

| HM - GTA - 100 - 080 | 10000.0 | 45.0 | 4.5 | 0.3 | 0.8 | 8.0 | 20.0 |

| HM - GTA - 120 - 080 | 12000.0 | 53.3 | 5.4 | 0.7 | 1.3 | 17.8 | 31.8 |

| Picture |  | ||||||

| Suit for | Copper Cable, Cover Cable,Bare Aluminum Cable, ACSR, ACSS, AAC, ABC, Bare Cu Cable, Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GTB -120 - 125 | 12000 | 54 | 5.4 | 0.7 | 1.25 | 18 | 32 |

| Picture |  | ||||||

| Suit for | Copper Cable, Cover Cable,Bare Aluminum Cable, ACSR, ACSS, AAC, ABC, Bare Cu Cable, Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GTC- 050 - 080 | 5000 | 20 | 2 | 0.2 | 0.8 | 5 | 22 |

| Picture |  | ||||||

| Suit for | Copper Cable, Cover Cable,Bare Aluminum Cable, ACSR, ACSS, AAC, ABC, Bare Cu Cable, Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GAA - 015 - 120 | 1500 | 6.8 | 0.68 | 0.8 | 1.2 | 2.03 | 5.08 |

| Picture |  | ||||||

| Suit for | Copper Cable, Cover Cable,Bare Aluminum Cable, ACSR, ACSS, AAC, ABC, Bare Cu Cable, Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GFB - 200 -180 | 20000 | 90.0 | 9 | 1.24 | 1.8 | 31.5 | 45.7 |

| Picture |  | ||||||

| Suit for | Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GJA - 050 - 075 | 5000 | 20 | 2 | 0.28 | 0.75 | 7 | 20 |

| Picture |  | ||||||

| Suit for | Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GJB - 015 - 080 | 2000 | 9 | 0.9 | 0.75 | 1.25 | 1.9 | 3.2 |

| Picture |  | ||||||

| Suit for | Guy Wire, Wire Rope, Barbed Wire, Trolley Wire | ||||||

| Code | WLL | Cable Diameter | |||||

| Unit | lbs | KN | Ton | in | mm | ||

| HM - GJC - 025 - 063 | 2500 | 10 | 1 | 0.1 | 0.63 | 2.5 | 16 |

| Picture |  | ||||||

| Code | WLL | Cable Diameter | |||||

| lbs | KN | Ton | in | mm | |||

| HM-GJD-080-076 | 8000 | 35.6 | 3.63 | 0.28 | 0.76 | 7.1 | 19.2 |

HULK Metal's Jaw Wire Pullers are engineered for safe and efficient cable tensioning across various applications. Made from high-performance alloy steel with hot die forging, they feature two jaw designs—cam and parallel—to suit different wire types. Built-in springs, side baffles, and anti-slip teeth ensure secure gripping, prevent slippage, and protect cable integrity. Each unit undergoes strict inspections, guaranteeing reliability, durability, and high performance in demanding industrial and construction environments.

The Jaw Wire Puller is a special Wire Puller designed to tighten various wires. It is often used in power construction, communication line installation and tension equipment. Its "Jaw" has carefully designed inverted teeth that can increase resistance while protecting the wire. The opening range of the jaws is related to the cable diameter.

The fixed jaw is straight and the movable jaw is cam design. Only the movable jaw has inverted teeth. As the cable is tightened, the movable jaw and will be more and more tightly clasped, the clamping force increases, and the resistance increases accordingly. This type of Jaw Wire Puller is more suitable for thicker and harder wires, such as steel wire rope, bare aluminum wire, etc.

The other type of fixed jaw and movable jaw are both straight and parallel, and both jaws are covered with shallow anti-slip teeth. This type of Jaw Wire Puller has a larger contact surface with the cable and can provide greater resistance, so even cables with weaker tensile performance can withstand greater tension, and it can protect the material of the cable clamping point from less damage. Almost all cables can be tightened using it.

The function of the side baffle is to provide lateral force to prevent the cable from coming out from the side after tightening.

Their built-in spring is designed to automatically close the Jaw Wire Puller after we manually open it and put the cable in, and provide an initial clamping force so that the operation can proceed smoothly.

The Jaw Wire Puller works by using its specially designed jaws to grip the cable securely. Once the wire is placed between the jaws, the built-in spring provides an initial clamping force. As tension is applied during pulling, the jaws automatically tighten, increasing friction and holding strength without damaging the cable surface. For cam jaw pullers, the movable cam jaw bites deeper as the load increases, ensuring a firm grip on harder wires. For parallel jaw pullers, both jaws close evenly, spreading the pressure across a larger area to protect softer cables while maintaining strong resistance.

Ideal for power line construction, ensuring safe and efficient cable tensioning during installation.

Widely used in telecommunication line projects, where stable grip prevents cable slipping and damage.

Suitable for steel wire rope, aluminum conductor, copper cable, and ABC cable tensioning tasks.

Excellent choice for overhead line maintenance, allowing reliable re-tensioning and secure holding force.

Effective in bridge, railway, and industrial wiring projects where strong pulling force is required.

Designed for utility contractors and electrical installers needing durable, ISO-certified tools.

Works with varied diameters (1.9mm–45.7mm), making it versatile across industries.

Jaw Wire Puller Supplied by HULK Metal is made of high-performance alloy steel through hot die forging. It has stronger performance.

Its body, movable jaw, and handle are all made of hot die forging, the baffle is made of laser cutting, and the spring is made of high-elastic steel bending.

Its surface treatment is electrogalvanized with an average coating thickness of 5μm.

3.6 Need to Pay Attention When Choosing the Right Jaw Wire Puller

Confirm that the maximum jaw opening of the Wire Puller can accommodate the largest outer diameter of your cable, wire rope, or conductor to avoid mismatch.

Ensure the rated pulling force of the Wire Puller meets the required tensile strength for your specific project application.

Understand the safety factor in testing—ultimate tensile force is usually tested at 2 times safety factor, while safe working load is typically calculated at 1.5 times.

Choose a supplier with advanced forging and machining factories, stable raw material sourcing, and large-scale production lines. Adequate capacity ensures consistent quality, shorter lead times, and the ability to handle both small and bulk orders without delay.

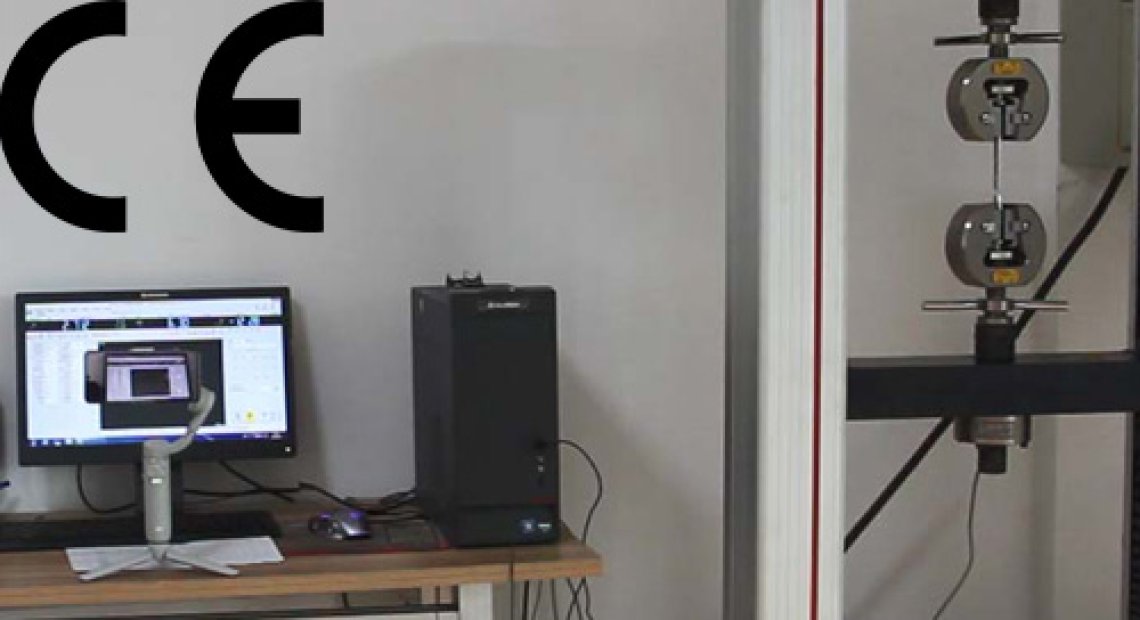

A reliable supplier should have ISO 9001 certification and a complete quality control process. Look for dimensional checks, tensile strength testing, salt spray testing, and detailed inspection reports to guarantee the Wire Puller can meet international standards and project requirements.

Strong suppliers provide engineering support, including customized jaw designs, material selection advice, and usage guidance. This technical backing helps you choose the most suitable Wire Puller model, reduces risks during installation, and improves project efficiency with less trial and error.

Consider whether the supplier offers timely communication, problem-solving support, and replacement guarantees. Reliable after-sales service ensures long-term cooperation, reduces downtime when issues arise, and gives you confidence that your investment in Wire Pullers will be protected throughout usage.

Select a supplier with proven export experience to multiple regions, including Europe, North America, and Southeast Asia. Such suppliers understand international logistics, packaging standards, and documentation requirements, making cross-border transactions smoother and reducing the risks of shipping delays or compliance issues.

A: We operate a professional quality inspection center equipped with advanced instruments, implement rigorous testing procedures, and follow ISO 9001 management standards. Every batch of Jaw Wire Pullers undergoes dimensional, tensile, and performance inspections to ensure consistent product reliability and durability.

A: Prices vary depending on product size, surface treatment, and order volume. Because we own factories, we can provide accurate real-time quotations. Bulk orders typically receive preferential pricing without compromising on the consistent quality standards of HULK Metal products.

A: Our prices are already competitive under equal quality conditions. However, larger orders and long-term cooperation usually allow more favorable discounts. Discussing detailed requirements with our team ensures the most cost-effective solution while maintaining strict quality assurance for your projects.

A: MOQ requirements depend on the size and specifications of the product you need. Some standard models are available with smaller order quantities. For accurate information and to secure the most favorable terms, please contact us directly with your requirements.

A: Delivery schedules depend on order size and customization requirements. Standard orders generally take around 30 days, while large or complex projects may extend to 45 days. We also provide expedited scheduling services for urgent projects requiring faster lead times.

A: We provide electrogalvanized finishes with passivation treatment to ensure corrosion resistance and longer service life. The average coating thickness is 5μm. Each batch undergoes strict surface quality checks to guarantee uniformity and protection against wear, rust, and harsh environments.

A: HULK Metal exports Wire Pullers to more than 50 countries worldwide, including Europe, North America, South America, Africa, and Southeast Asia. With rich international logistics experience, we guarantee smooth shipping, proper packaging, and timely delivery to your project sites.

A: Our Wire Pullers are manufactured from high-performance alloy steel using hot die forging. This process creates a dense internal structure, enhances tensile strength, and ensures durability. Components such as jaws, handles, and baffles undergo precise machining and strict quality testing.

A: We provide Wire Pullers suitable for cables ranging from 1.9 mm to 45.7 mm in diameter, with rated load capacities between 1,500 lbs and 20,000 lbs. Two jaw types are available to cover different application scenarios and material requirements.

A: We support flexible payment methods including T/T, L/C, and negotiated terms for large orders. Delivery terms include FOB, CIF, and EXW depending on customer preference. Our logistics team ensures accurate documentation and smooth cross-border transportation for all shipments.

A: Each batch undergoes rigorous tensile testing. We apply a force of 1.5 times the safety factor to confirm safe working load and 2 times the safety factor to determine ultimate tensile strength. Detailed test reports accompany all qualified orders.

A: Our Wire Pullers are suitable for a wide range of conductors including steel wire rope, bare aluminum wire, copper cable, insulated cable, and ABC cable. Parallel jaw models handle softer conductors well, while cam jaw models are ideal for harder wires.

GripMaster pullers are crafted from premium alloy steel, providing exceptional resistance to deformation, wear, and corrosion. This ensures long-term reliability even under repeated heavy-duty industrial or utility use, making it a dependable choice for demanding projects.

Its precision-engineered jaws firmly clamp onto cables and wires, preventing slippage during tensioning. This secure grip reduces accidents and maintains stable performance, even when handling high-tensile or large-diameter cables.

GripMaster’s handles are designed for operator comfort, minimizing fatigue during prolonged operations. The ergonomic grip allows safer handling and smoother tensioning, improving efficiency on site.

Available in multiple load capacities, GripMaster pullers can manage light to heavy cables across different industries. This versatility makes it suitable for construction, utility, and industrial applications requiring various tensioning needs.

Constructed with high-strength steel, PowerGrip pullers resist bending or structural damage under extreme pulling forces. Ideal for industrial applications, they maintain consistent performance even in tough environments.

The specially designed jaw teeth maximize friction while protecting cable surfaces from wear and deformation. This allows operators to apply maximum pulling force without damaging expensive wires.

Integrated spring mechanisms allow easy opening and automatic jaw closure. This feature enhances operational speed and safety, ensuring the cable is firmly secured before tensioning begins.

Suitable for steel, aluminum, and copper cables of varying diameters. PowerGrip pullers provide flexibility across diverse project requirements, making them a versatile tool for contractors and utility professionals.

CablePro pullers are made of alloy steel, providing superior tensile strength and extended service life. These pullers can handle repeated industrial or field use without performance degradation.

Side baffles and integrated safety latches prevent accidental cable release during tensioning. This design ensures safer operation for technicians and reduces the risk of project delays.

The modular design allows quick replacement of worn jaws or handles without specialized tools. This reduces downtime and maintenance costs, keeping projects on schedule.

Each unit undergoes dimensional checks, tensile tests, and rigorous inspections, ensuring consistent performance and reliability even under demanding working conditions.

Klein Tools is globally recognized for reliability, precision, and quality in professional electrical and utility markets. Choosing Klein ensures proven performance in critical projects.

Ergonomic handles reduce strain during prolonged operation, increasing efficiency and operator safety. This design is particularly useful in field environments where long hours of work are required.

Offers multiple jaw designs to accommodate various wire diameters and materials. Klein Tools provide flexibility for different projects, from power lines to communication cable installation.

Electrogalvanized or coated surfaces extend service life and withstand outdoor environmental conditions, maintaining reliability in both industrial and construction settings.

Built to handle heavy-duty industrial and utility applications, Greenlee pullers resist extreme forces without structural compromise, ensuring reliable tensioning on large or high-strength cables.

Carefully engineered jaws provide maximum grip while protecting cables from deformation or surface damage. This design is suitable for delicate or high-value conductors.

Integrated spring mechanisms and intuitive designs make inserting and tensioning cables faster, safer, and more efficient for technicians in the field.

Supports steel, aluminum, copper, and mixed conductor cables of varying diameters, making it a versatile solution for diverse industrial and construction projects.

Forged steel bodies ensure long-term durability under repeated heavy use, making them reliable in industrial, construction, and utility applications.

Even pressure distribution across the jaws ensures consistent grip on all cable surfaces, reducing the risk of slippage and cable damage.

Maintains steady pulling force during repetitive operations, ensuring efficiency and safety in high-demand environments.

Surface treatments prevent rust and abrasion, extending the lifespan of the puller and maintaining optimal performance over time.

Crosby is trusted globally for safety-critical lifting and pulling applications. Their pullers meet strict industry standards, ensuring dependable performance in demanding conditions.

Designed to handle large-diameter cables and high tensile loads efficiently, making them suitable for industrial and utility applications.

Galvanized or coated surfaces protect against corrosion, abrasion, and environmental damage, prolonging service life and maintaining performance.

Compatible with steel, aluminum, and mixed conductor cables, suitable for diverse industrial, construction, and utility projects worldwide.

Hot die-forged for dense internal structure and maximum tensile strength, HULK Metal pullers endure heavy loads and harsh working conditions reliably.

Cam and parallel jaws allow handling of both soft and hard cables. The design minimizes damage while providing a strong and stable gripping force.

CMM, hardness, salt spray, and tensile testing ensure each batch achieves a 99.99% qualification rate, guaranteeing reliable performance for bulk orders.

Streamlined production, efficient supply chain, and ISO-compliant processes provide competitive pricing for bulk buyers without compromising quality or delivery speed.

HULK Metal ensures that every Jaw Wire Puller delivered meets strict international quality standards. Our ISO 9001–certified system covers the entire production process, from raw material selection to final inspection. Using advanced testing instruments, we verify dimensional accuracy, tensile strength, surface treatment, and durability. Each batch is accompanied by detailed inspection reports to guarantee product consistency, high reliability, and long-term performance in demanding construction and industrial applications.

We use CMM, vernier calipers, and specialized gauges to measure all key dimensions. This ensures that jaws, handles, and components precisely match drawings and maintain stable performance.

Before shipment, random samples are inspected for strength, coating uniformity, and assembly quality. Only products passing all checks are packed and prepared for delivery.

Wire Pullers undergo simulated working condition tests to confirm reliable gripping performance, smooth operation, and consistent safety factor requirements, ensuring stable use in field applications.

Each order is double-checked against the packing list and purchase contract to ensure complete quantities, correct models, and accurate specifications before dispatch.

Here we show the forging and surface treatment factories and our quality control center for Jaw Wire Puller production. You can click to learn more and contact us to visit them.

We have a fully automatic blanking machine that can cut steel bars into the same size. Electromagnetic induction heating tubes can heat the steel bars to the specified temperature and push the blanks to the next process. Experienced employees use free forging to pre-treat the blank shape before putting it into the forging die. The whole process is safe and efficient. You can contact us at any time to schedule an appointment to visit the factory.

Our quality control center has a CMM, a vernier caliper, an electron microscope, a hardness tester, a photometer, a salt spray tester, a tensile tester, and other instruments. It can fully test the physical and chemical properties of the Jaw Wire Puller and the necessary mechanical properties. Each batch of orders is accompanied by a detailed test report.

The different parts of the Jaw Wire Puller are made in a central electrogalvanizing factory that works closely with us and uses modern rack plating technology. The coating of the components is more uniform and beautiful. The electrogalvanizing factory has cooperated with us for 15 years, and each batch of galvanized components undergoes strict sampling inspection; only those that pass the inspection are used in the assembly of the finished product.

We have passed ISO9001 certification and will strictly implement it. Through our perfect supply chain and our excellent service, you can experience one-stop procurement with less effort and time and receive high-quality and low-cost Jaw Wire Pullers.

Choosing HULK Metal's Jaw Wire Puller, you will enjoy a true one-stop procurement experience. From raw material procurement, forging, heat treatment, to surface plating, to final assembly and quality inspection, the entire process is completed in our perfect supply chain system. You don't need to run between multiple suppliers. Our procurement team will coordinate in time according to your needs to ensure that each Jaw Wire Puller can meet the drawing specifications and operating conditions. This not only reduces communication costs, but also avoids delays and quality risks caused by multiple connections, so you can save worry and rest assured.

HULK Metal's Jaw Wire Puller is made of high-performance alloy steel hot die forging to ensure that the material has a dense internal structure and high tensile strength. Two optional jaw designs (straight jaws and curved jaws) can cover a variety of cables and wire ropes from 1.9 mm to 45.7 mm to meet the tensioning needs in different scenarios. All components undergo strict size and performance testing before assembly, including CMM measurement, hardness testing, salt spray testing, etc. After the final assembly is completed, each batch of Jaw Wire Puller will also be sampled, and the qualified rate can reach 99.99%. Excellent product stability ensures that you can reduce the failure rate and improve work efficiency during use.

Relying on HULK Metal's complete industrial chain advantages, we can achieve scale effects in raw material procurement, production and processing, and logistics, thereby greatly reducing the manufacturing cost of each piece. Under the same quality and performance standards, the price of Jaw Wire Puller we provide is more competitive. At the same time, due to the high factory qualified rate of products, the maintenance and replacement costs during use are also reduced accordingly. Long-term cooperative customers can also enjoy tiered discounts and customized value-added services to further reduce the overall procurement cost. Choosing HULK Metal means obtaining greater cost-effectiveness while ensuring quality.

Under the traditional procurement model, different parts and processing procedures often require multiple communications and confirmations, which consumes a lot of time. At HULK Metal, you only need to place an order once, and we will manage it in accordance with ISO 9001 standards. From order confirmation to packaging and shipment, each link is tracked by a dedicated person and real-time feedback is provided. For urgent projects, we can also provide expedited production scheduling services to ensure that the Jaw Wire Puller can be delivered in the shortest possible time. It saves the trouble of repeated communication with multiple suppliers, allowing you to focus on your core business without worrying about the project schedule.

We have multiple automated forging production lines and efficient surface treatment workshops across the country, with sufficient and stable production capacity. At the same time, due to long-term cooperation with many high-quality logistics service providers, we can arrange land, air or sea transportation for you as soon as possible to meet the delivery needs of different projects. Even for large-volume orders, the production cycle of Jaw Wire Puller can be compressed to the shortest through scientific scheduling. In addition, our after-sales team will confirm the arrival time with you in advance and provide clear logistics tracking information to ensure the safety and timely delivery of the goods, so as to help your project start and implement on time.

Here are some technical contents about Jaw Wire Puller that we have compiled. You can click to learn more about them.

In addition to Jaw Wire Pullers, HULK Metal supplies a full range of professional pulling tools, including parallel jaw wire pullers, cam jaw wire pullers, come along clamps, aluminum cable grips, and steel wire rope pullers. Each model is designed to meet different wire tensioning needs, from power line installation to communication cable projects. With ISO-certified production, strong load capacities, and versatile specifications, our wire pullers ensure safety, durability, and efficiency across diverse construction and industrial applications.

HULK Metal's Jaw Wire Cable Puller Grippers are designed to provide strong grip, smooth pulling, and enhanced safety in cable tensioning applications. Built with high-quality materials and advanced manufacturing techniques, our pullers deliver consistent performance under demanding conditions. Whether you need sawtooth-type or round-type models, our range meets various load capacities and cable sizes. Backed by strict quality control and comprehensive production capabilities, we ensure each gripper meets international standards. With OEM services available, we help customers worldwide get customized solutions that fit their exact cable pulling needs.

HULK Metal offers durable come along clamps engineered for high performance in overhead line construction and industrial cable installation. Each clamp provides a strong, slip-resistant grip on conductors, ensuring safe tensioning and pulling.

HULK Metal provides a wide range of wire grips designed for copper cables, aluminum conductors, guy wires, and steel ropes. Our Wire Pulling Grips are precision-forged, durable, and tested to handle demanding loads without damaging conductors.

As a Chinese manufacturer of heavy-duty Wire Rope Puller Tools, we hope to provide high-quality products to more customers around the world. To this end, we will pay more attention to the quality of the products and improve their performance while ensuring the overall quality.

We can provide steel jaw cable puller with wire diameter ranging from 2.03mm to 45.7mm and from 0.68 tons to 9 tons. Contact us to get the best price.

We can currently produce a variety of high-performance alloy steels that can be used for wire diameters between 0.08~1.8in (2.03~45.7mm), tensions between 1500~20000lbs (0.68~9tons) and for various wire types of Jaw Cable Gripper.

Steel Wire Rope Gripper is made of high-performance alloy steel by hot die forging. It has a variety of styles to suit more wires.

HULK Metal offers a versatile range of Jaw Grip Puller for Aluminum Cable models, from lightweight wire grip pullers to heavy-duty cable pulling tools. With OEM customization, advanced production lines, and stringent quality controls, we ensure performance, durability, and after-sale support.

ABC Conductor Grips are special tools designed for ABC wire pulling, tightening and other working environments. Its clamp can better protect the ABC when pulling. We offer a variety of ABC Conductor Grips. Contact us for better prices.

The Jaw Rope Puller is designed for tensioning and routing ropes, cables, wire ropes, etc. We can currently provide Jaw Rope Pullers with clamping wire diameters ranging from 1.9mm to 45.7mm and pulling forces ranging from 1500 to 20000LBS.

Jaw Wire Puller orders will undergo strict sampling inspections before leaving the factory to ensure that the order qualification rate can reach 99.99%. We provide QA services. You can purchase with confidence.

Guy wire jaw grip puller is a tool designed to clamp wires and provide a fulcrum for tensioning them. It is simple to operate and can protect the wires while providing a stronger clamping force. We are a Chinese factory and can provide products with higher cost performance.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU