We measure every critical dimension of jaws, handles, and springs to ensure proper fit. Precise dimensions guarantee smooth operation, secure gripping, and compliance with customer specifications.

Heavy duty Wire Rope Puller Tools are one of our main products. They are made of high-performance alloy steel and can withstand greater tension. The spring in the structure has a longer telescopic life, allowing it to be used more times. We use galvanizing to improve the rust resistance of heavy duty Wire Rope Puller Tools, so it can be stored for a longer time.

1. 2500 LBS to 20000 LBS

2. Suitable for Copper Cable, Coverd Cable, Guy Wire, Wire Rope, ABC, Bare Aluminum, ACSR, ACSS, AAC.

3. Various of Types and Surface Finishing

4. Bigger Order Cheaper Price

5. QA Service

6. Comprehensive After Service

Heavy duty wire rope pulling tools are one of our main products. They are made of high-performance alloy steel and can withstand greater tension. The spring in the structure has a longer telescopic life, allowing it to be used more times. We use galvanizing to improve the rust resistance of heavy duty wire rope pulling tools, so it can be stored for a longer time.

This Heavy Duty Wire Rope Puller Tool is designed for a wide range of cables and wire ropes, including copper, aluminum, ACSR, ACSS, AAC, ABC, guy wires, barbed wires, and trolley wires. Made with high-performance alloy steel and treated with galvanizing, it offers excellent corrosion resistance. The specifications cover working load limits, cable diameters, and codes, making it easy for bulk buyers to select the right tool for their projects.

Heavy Duty Wire Rope Pulling Tools | |

MOQ | 20 |

Material | High Strength Alloy Steel |

Surface | Galvanized |

Cable Diameter | 0.08~1.8in / 2.03~45.7mm |

WLL | 1500~20000lbs / 0.68~9tons |

The Heavy Duty Wire Rope Puller Tool is a high-performance cable pulling solution designed for professional use. With a 20,000 lbs working load, it efficiently grips and tension cables, wire ropes, and other conductors. Its durable alloy steel construction, spring-assisted jaws, and anti-slip features ensure safety, reliability, and extended service life. Ideal for various industrial, utility, and construction applications, this tool provides superior performance and long-term usability for bulk buyers and contractors.

The Heavy Duty Wire Rope Puller Tool features parallel jaws capable of withstanding up to 20,000 lbs working load. Beyond simply tensioning wire ropes, it is suitable for multiple tasks, including pulling, lifting, and securing cables. Its robust design ensures safety during heavy-duty operations, making it an essential tool for professional cable installation, construction, and utility maintenance projects.

The tool has a fixed jaw and a movable jaw, both crafted from high-strength alloy steel. An internal spring provides initial gripping force when the jaws close. The handle includes a hole for attaching hooks or additional tools. On the jaw's exterior, anti-slip plates prevent cables from slipping during operation. This design ensures secure gripping, reliable performance, and long service life even under heavy loads.

To operate, position the jaws around the cable or wire rope, allowing the spring to engage the initial grip. Pull the handle or lever to increase tension, while the movable jaw locks the cable securely. The anti-slip plates prevent slippage during pulling or lifting. Once tensioning is complete, release the handle gradually to avoid sudden cable movement. This simple mechanism ensures precise control and safe, efficient cable handling.

The Heavy Duty Wire Rope Puller Tool is widely used in power and utility line installation. It helps tension ACSR, AAC, and ACSS conductors securely during overhead cable stringing. Its strong grip and load-bearing capacity ensure safety, reducing slippage and breakage, while improving efficiency for linemen working in demanding field environments.

In construction sites, this puller tool is applied for pulling steel wire ropes and guy wires to stabilize temporary structures, scaffolding, or towers. Its ability to hold and tension heavy loads guarantees secure anchoring. The tool's high durability and reliability make it essential for large-scale construction and civil engineering projects.

Farmers and contractors use the tool for tightening barbed wire and high-tensile fencing cables. It ensures fences are securely stretched and properly aligned, preventing sagging over time. The strong jaws and anti-slip design make the installation process faster, reducing labor intensity and ensuring long-lasting fence stability in various farm applications.

The tool is valuable in industrial plants where wire ropes are used for lifting, securing, or supporting heavy equipment. It allows technicians to adjust, tension, or replace wire ropes quickly and safely. With its high load capacity and robust design, it meets the strict requirements of industrial maintenance operations.

Confirm that the dimensions of the Wire Rope Puller Tool meet the requirements of your cable system to ensure safe operation.

Ensure that the jaws are suitable for the specific type and diameter of cable in use, providing a secure grip and preventing slippage.

A reliable supplier must own a professional factory with advanced production equipment. Strong manufacturing capability ensures stable quality and on-time delivery. By working directly with a manufacturer instead of a trading company, you can gain better control over product consistency, pricing, and customization options for your Wire Rope Puller Tools.

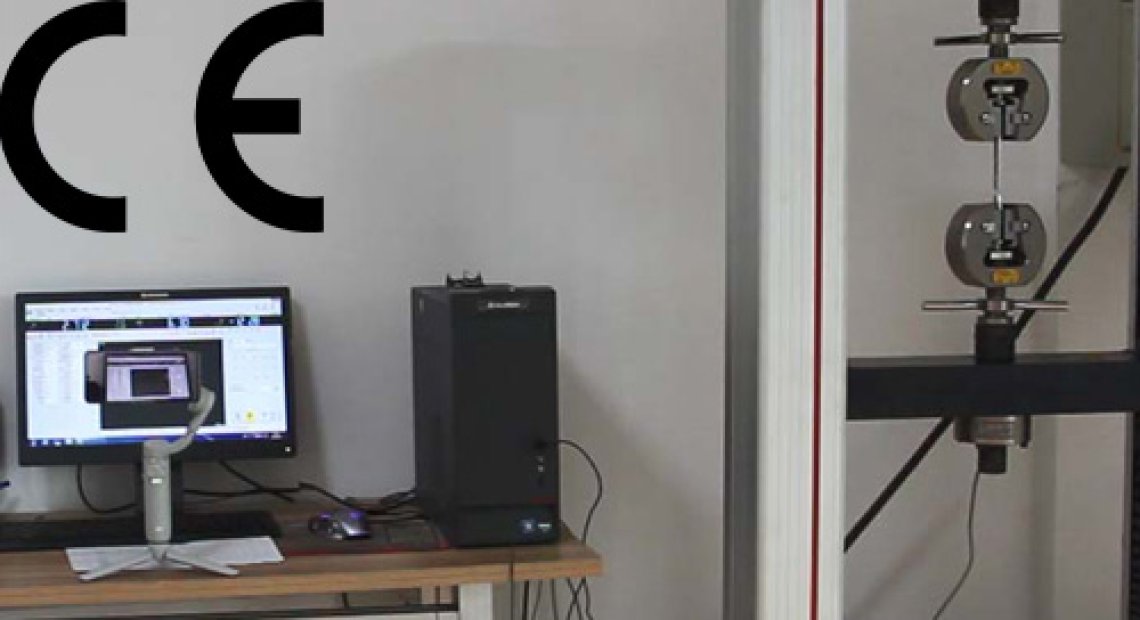

Choose a supplier with a complete quality inspection system, including dimensional checks, tensile testing, and pre-shipment inspections. A supplier committed to strict quality standards guarantees that every puller tool meets international safety requirements, reducing risks of failure during use and ensuring long-term reliability for your cable and wire projects.

A suitable supplier should provide competitive and transparent pricing based on raw materials, order volume, and surface treatment. Fair pricing policies help you balance quality and cost. Bulk buyers benefit from economies of scale, ensuring they receive high-quality Wire Rope Puller Tools at affordable and sustainable procurement costs.

Suppliers with a dedicated after-sales service team can offer faster response times for technical support, replacement parts, or returns. This ensures that any quality concerns or operational issues are addressed quickly. Good after-service builds trust, reduces downtime, and improves overall efficiency in your large-scale cable installation projects.

Select a supplier with proven export experience to multiple regions, including Europe, North America, and Southeast Asia. Familiarity with international logistics, packaging, and certifications ensures smooth delivery. A supplier with global experience can provide tailored solutions that meet the diverse requirements of clients across different markets and industries.

A: We operate a fully equipped inspection center with professional testing equipment. Each Wire Rope Puller Tool goes through strict dimensional checks, load tests, and surface inspections to meet international standards, ensuring stable performance and long-term durability for every order.

A: Prices vary depending on raw materials, specifications, surface treatments, and order quantities. Since we own our factory, we can provide real-time quotations and cost-effective pricing while maintaining consistent quality standards across all Wire Rope Puller Tool models.

A: Larger order volumes always help reduce costs. With equal quality levels, we guarantee lower pricing than many competitors. Discussing surface treatments, packaging, and delivery terms in advance also allows us to tailor more favorable quotations for bulk buyers.

A: The minimum order quantity depends on tool specifications and surface finishing. Smaller models usually have lower MOQs, while customized designs require larger runs. Contact our sales team anytime to receive accurate information and tailored quotations for your requirements.

A: Generally, orders are completed within 30 days, depending on production volume and customization. For larger orders, efficiency increases, and timelines can be shortened. In most cases, production will not exceed 45 days, ensuring reliable on-time delivery worldwide.

A: We provide hot-dip galvanizing, double-coating galvanizing, and powder coating with customized colors. Please note that powder coating requires a MOQ. Each finish improves rust resistance and durability, allowing you to select the most suitable treatment for your application.

A: We have successfully exported to over 50 countries, including Europe, North America, South America, Africa, and Southeast Asia. With rich global trade experience, we ensure safe packaging, smooth customs clearance, and efficient delivery of Wire Rope Puller Tools.

A: We can manufacture in cast iron, stainless steel, and aluminum. Currently, we hold a complete set of molds for cast iron models. For stainless steel or aluminum versions, we can provide OEM production with new mold development.

A: We provide a wide range of sizes suitable for different wire ropes and cables. From smaller models for light-duty use to heavy-duty pullers up to 20,000 lbs WLL, we can supply sizes based on your specific requirements.

A: We support flexible payment methods such as T/T, L/C, and Western Union. Delivery terms include FOB, CIF, and EXW depending on customer requirements. This flexibility ensures smoother cooperation and better cost control for our international clients.

A: We apply tensile testing with a safety factor of 1.5 times for working load and two times for ultimate load. This ensures every puller tool is reliable, safe, and durable under demanding cable tensioning operations.

A: Our puller tools suit copper cables, aluminum conductors, ACSR, ACSS, AAC, ABC, bare Cu cables, guy wires, barbed wires, trolley wires, and wire ropes. Their strong jaws guarantee secure gripping and safety across multiple industrial and utility applications.

A: HULK Metal is a manufacturer with its own factory. We provide comprehensive support, including technical consulting, procurement solutions, and foreign trade services, allowing bulk buyers to source high-quality Wire Rope Puller Tools directly from a reliable Chinese supplier.

We begin by carefully reviewing customer requirements, including surface treatments, order quantity, packaging methods, delivery terms, and payment conditions. This ensures we provide tailored solutions and accurate production planning, meeting both technical standards and commercial expectations for Wire Rope Puller Tools.

High-performance alloy steel is sourced from trusted suppliers. Each batch undergoes strict quality inspections for composition, strength, and durability. Only certified raw materials enter production, guaranteeing the Wire Rope Puller Tools maintain superior load-bearing capacity, corrosion resistance, and consistent performance.

Production follows strict processes to ensure precision and efficiency. Every stage, from forging to final assembly, is monitored by skilled technicians. This guarantees the Wire Rope Puller Tools meet international standards, while reducing defects and ensuring reliable, long-lasting cable pulling performance.

The jaws and structural components are forged from alloy steel under controlled temperatures. Forging improves material density and strength, eliminating weak points. This process ensures each part can handle heavy working loads, providing maximum safety and extended life for the tool.

After forging, parts are machined for precision and smoothness. Edges are deburred, holes are drilled, and surfaces are polished to required tolerances. Accurate finishing guarantees better jaw alignment, smoother operation, and improved durability in real-world cable tensioning and wire rope applications.

Dimensional inspections and strength tests are performed on finished parts. We check alignment, hardness, and load capacity to ensure every component meets strict specifications. This prevents assembly issues, improves performance, and ensures consistent safety standards across every Wire Rope Puller Tool.

Each part undergoes electro-galvanizing and passivation to improve corrosion resistance. This treatment prevents rusting during storage and field use. Surface finishing also enhances tool durability and appearance, allowing the puller tools to maintain performance in harsh outdoor and industrial environments.

All components, including jaws, springs, handles, and safety plates, are assembled by skilled workers. During assembly, every moving part is checked for smooth operation. This ensures the Wire Rope Puller Tool delivers reliable gripping force and consistent performance under heavy loads.

Final assembled tools undergo tensile testing, load testing, and safety checks. Each Wire Rope Puller Tool must meet a 1.5× working load factor and 2× ultimate load factor. Only fully qualified products are approved for packaging and delivery to customers.

Tools are packaged in strong, moisture-resistant cartons or wooden cases, based on customer requirements. Labels and codes ensure easy identification. Efficient logistics partners support timely worldwide shipping, ensuring Wire Rope Puller Tools arrive safely and on schedule for bulk buyers.

Upon receipt, customers can inspect quality and quantity. Any product with defects or quality concerns can be returned, exchanged, or restocked. Our after-sales team provides timely support, ensuring satisfaction and long-term cooperation with buyers in different international markets.

GripMaster wire rope pullers are engineered to handle heavy loads safely. With robust alloy steel construction, they provide high tensile strength, allowing users to lift, pull, or tension wire ropes with maximum reliability.

The parallel jaws ensure secure gripping without damaging cables. The movable jaw and spring mechanism provide consistent bite, preventing slippage during high-tension operations for safer, more efficient wire handling.

Built with premium materials and corrosion-resistant coatings, GripMaster pullers withstand harsh outdoor environments. They maintain long-term performance under frequent use, reducing maintenance needs and extending service life.

Ergonomic handles and easy-to-operate levers allow precise control during tensioning. Lightweight design and well-balanced construction reduce operator fatigue, improving efficiency and safety in industrial or utility applications.

Klein Tools wire rope pullers are made from durable alloy steel, capable of withstanding heavy loads. Their robust design ensures safe and reliable performance for demanding industrial and utility applications.

The pullers feature expertly engineered jaws that provide secure and consistent cable gripping. The design minimizes slippage, protecting both the tool and the wire rope during tensioning operations.

Klein Tools uses advanced surface treatments, including galvanizing, to protect against rust and corrosion. This ensures long-lasting durability, even when exposed to outdoor or harsh environmental conditions.

Handles and levers are designed for comfort and ease of use, reducing operator fatigue. This allows efficient tensioning and pulling, improving productivity while maintaining safety in various field operations.

HULK Metal wire rope pullers are designed to handle extremely heavy loads safely. Constructed from high-performance alloy steel, they provide reliable tensioning and pulling for industrial and utility applications.

Each tool undergoes electro-galvanizing and passivation treatments, ensuring long-term resistance to rust and wear. This durability allows repeated use in harsh outdoor environments without compromising performance or safety.

The fixed and movable jaws, combined with internal springs, ensure consistent gripping force. Anti-slip plates prevent cable slippage, allowing safe and accurate tensioning of various wire types.

HULK Metal provides high-quality tools at competitive prices. With OEM and customization options, bulk buyers can receive tailored solutions, ensuring cost-effectiveness while maintaining superior performance and reliability.

Greenlee wire rope pullers are engineered to handle heavy-duty loads safely. Their robust alloy steel construction ensures consistent performance during demanding cable tensioning and pulling operations in industrial and utility environments.

The pullers feature precision-engineered jaws that securely grip wires without slipping. The combination of fixed and movable jaws with spring-assisted action provides stable tension and prevents cable damage.

Greenlee tools are coated with advanced rust-resistant treatments. This surface protection extends service life, allowing repeated use in outdoor and harsh environmental conditions while maintaining tool strength and reliability.

Handles and levers are ergonomically designed for comfortable operation. This reduces operator fatigue, improves efficiency, and ensures safer handling during prolonged cable installation or maintenance tasks.

CAMPBELL wire rope pullers are designed for extreme loads, ensuring safe and reliable tensioning. Their alloy steel construction maintains strength under heavy-duty industrial and utility applications, minimizing risk of failure.

The jaws are engineered for consistent gripping, preventing slippage during wire rope tensioning. Spring-assisted jaws maintain steady pressure, ensuring secure operation and reducing damage to cables.

CAMPBELL pullers are treated with galvanizing and rust-resistant coatings. This enhances long-term durability, making the tools suitable for harsh outdoor conditions and repeated heavy use without performance loss.

Ergonomic handles and efficient lever systems reduce operator fatigue, enabling precise control and smooth tensioning. This design increases productivity and ensures safer handling in industrial or field environments.

HULK Metal maintains strict quality control standards throughout every stage of production. From raw material testing to final assembly, each Wire Rope Puller Tool undergoes multiple inspections to guarantee safety, performance, and durability. Our QC team focuses on dimensional accuracy, usage reliability, tensile strength, and packaging standards, ensuring customers always receive heavy-duty tools that meet international requirements. With rigorous testing and systematic checks, we provide confidence in every tool delivered.

We measure every critical dimension of jaws, handles, and springs to ensure proper fit. Precise dimensions guarantee smooth operation, secure gripping, and compliance with customer specifications.

Each batch undergoes thorough checks before shipping. Packaging, labeling, surface finishing, and tool integrity are verified to ensure safe transport and customer satisfaction upon delivery.

Every Wire Rope Puller Tool is tensile tested to 1.5× working load and 2× ultimate load capacity. This guarantees maximum safety and compliance with international tensile standards.

Tools are tested in simulated cable pulling conditions to confirm functionality. This ensures jaws grip properly, springs perform reliably, and the tool operates safely under heavy working loads.

We confirm all orders match required quantities. Each shipment is carefully counted, documented, and packaged to avoid shortages or errors, ensuring reliable supply for bulk orders.

HULK Metal's factory is equipped with advanced forging, machining, and surface treatment lines for producing Heavy Duty Wire Rope Puller Tools. We integrate raw material processing, precision forging, surface finishing, and final assembly under strict quality control. With professional technicians and efficient production management, our factory ensures stable quality, shorter delivery times, and competitive pricing. This comprehensive manufacturing capability allows us to provide high-standard Wire Puller Tools for global bulk buyers.

Our hot die forging factory forms the core strength of Wire Rope Puller Tool production. Using advanced forging equipment, we process high-performance alloy steel into dense, defect-free parts. Hot die forging improves metal grain structure, significantly enhancing load-bearing strength and tool durability. With strict control of temperature and pressure, our forged jaws and bodies achieve exceptional performance. This factory ensures that every Wire Rope Puller Tool can withstand heavy tension and demanding applications in industrial environments.

The QC center operates as an independent department, equipped with advanced testing machines. It performs dimensional checks, tensile strength testing, hardness measurement, and corrosion resistance analysis. Each production batch undergoes systematic inspection at multiple stages to ensure consistency and compliance with ISO standards. The center also conducts simulated usage testing, ensuring the jaws grip firmly without slippage. With this complete quality system, our QC center guarantees every Wire Rope Puller Tool meets customer requirements and international safety standards.

Surface treatment is performed in a dedicated workshop equipped with electro-galvanizing and passivation lines. Each tool undergoes rust-preventive treatment to enhance corrosion resistance. Galvanizing provides a durable protective coating, while passivation extends service life in outdoor and industrial conditions. Customized powder coating is also available upon request, offering color-coded solutions for different industries. By combining high-quality materials with advanced surface treatment, we ensure every Wire Rope Puller Tool retains its strength, appearance, and reliability even after long-term storage and usage.

Our Heavy Duty Wire Rope Puller Tool is manufactured with premium alloy steel, advanced forging technology, and strict quality inspections to ensure superior strength and reliability. With excellent load-bearing capacity, long service life, and professional OEM support, it's the trusted choice for demanding projects worldwide.

At present, we have produced 9 types of Jaw Cable Gripper molds, which can be used for clamping and tightening wires with diameters between 0.08~1.8in (2.03~45.7mm), Copper Cable, Coverd Cable, Guy Wire, Wire Rope, ABC, Bare Aluminum, ACSR, ACSS, AAC, etc. You can purchase Jaw Cable Gripper with a tension range of 1500~20000lbs (0.68~9tons) from us.

ISO 9001 certification is an endorsement of the quality of our products and services. Advanced forging equipment and experienced staff are the basis for us to produce high-quality Jaw Cable Gripper. Advanced testing equipment and professional quality inspection personnel provide a more important barrier for providing better products. Quality assurance service is our guarantee for you. You can purchase goods that meet your requirements from us.

We will be your office in China and handle all matters related to your order in China. In order to better serve every customer, we have formed a team including technical, purchasing, production, quality inspection, finance, logistics, after-sales and other personnel. They will be led by the sales manager and report the progress of the order to you in various ways. You only need to be in the office to know everything.

We can get raw materials of the same quality at a lower price. We can choose the most suitable process to complete the order according to the performance indicators of Jaw Cable Gripper, and reduce production costs while meeting the quality standards. Through our perfect supply chain, we can also save costs such as packaging, transportation, and international freight. We will share these savings with you. You can get a cheaper Jaw Cable Gripper from us.

Our technical team can develop a more complete production solution based on your delivery requirements. We can get materials from raw material suppliers faster, and the factory can complete production by more rationally arranging equipment and employees. After the goods are produced, they will be quickly transported to the next location by our own logistics team. For international freight, you can also find a more suitable company through our consulting center.

Here you can find insightful articles about Heavy Duty Wire Rope Puller Tools, including industry applications, technical guides, product comparisons, and maintenance tips. Each article is paired with images, titles, and summaries to help users better understand usage, performance, and selection of the right puller tools.

In addition to Heavy Duty Wire Rope Puller Tools, HULK Metal also produces Jaw Wire Pullers, Cable Grippers, Come Along Clamps, and Steel ABC Conductor Grips. These tools serve different installation and tensioning applications, ensuring you always have the right equipment for safe and efficient operations.

HULK Metal's Jaw Wire Cable Puller Grippers are designed to provide strong grip, smooth pulling, and enhanced safety in cable tensioning applications. Built with high-quality materials and advanced manufacturing techniques, our pullers deliver consistent performance under demanding conditions. Whether you need sawtooth-type or round-type models, our range meets various load capacities and cable sizes. Backed by strict quality control and comprehensive production capabilities, we ensure each gripper meets international standards. With OEM services available, we help customers worldwide get customized solutions that fit their exact cable pulling needs.

HULK Metal offers durable come along clamps engineered for high performance in overhead line construction and industrial cable installation. Each clamp provides a strong, slip-resistant grip on conductors, ensuring safe tensioning and pulling.

HULK Metal provides a wide range of wire grips designed for copper cables, aluminum conductors, guy wires, and steel ropes. Our Wire Pulling Grips are precision-forged, durable, and tested to handle demanding loads without damaging conductors.

As a Chinese manufacturer of heavy-duty Wire Rope Puller Tools, we hope to provide high-quality products to more customers around the world. To this end, we will pay more attention to the quality of the products and improve their performance while ensuring the overall quality.

We can provide steel jaw cable puller with wire diameter ranging from 2.03mm to 45.7mm and from 0.68 tons to 9 tons. Contact us to get the best price.

We can currently produce a variety of high-performance alloy steels that can be used for wire diameters between 0.08~1.8in (2.03~45.7mm), tensions between 1500~20000lbs (0.68~9tons) and for various wire types of Jaw Cable Gripper.

Steel Wire Rope Gripper is made of high-performance alloy steel by hot die forging. It has a variety of styles to suit more wires.

HULK Metal offers a versatile range of Jaw Grip Puller for Aluminum Cable models, from lightweight wire grip pullers to heavy-duty cable pulling tools. With OEM customization, advanced production lines, and stringent quality controls, we ensure performance, durability, and after-sale support.

ABC Conductor Grips are special tools designed for ABC wire pulling, tightening and other working environments. Its clamp can better protect the ABC when pulling. We offer a variety of ABC Conductor Grips. Contact us for better prices.

The Jaw Rope Puller is designed for tensioning and routing ropes, cables, wire ropes, etc. We can currently provide Jaw Rope Pullers with clamping wire diameters ranging from 1.9mm to 45.7mm and pulling forces ranging from 1500 to 20000LBS.

Jaw Wire Puller orders will undergo strict sampling inspections before leaving the factory to ensure that the order qualification rate can reach 99.99%. We provide QA services. You can purchase with confidence.

Guy wire jaw grip puller is a tool designed to clamp wires and provide a fulcrum for tensioning them. It is simple to operate and can protect the wires while providing a stronger clamping force. We are a Chinese factory and can provide products with higher cost performance.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU