We measure each anchor's dimensions with precision instruments to ensure conformity with drawings and tolerance requirements, preventing installation issues and ensuring compatibility with lifting clutches and recess formers.

HULK Metal provides high-quality precast concrete double head lifting pin anchors designed for reliable performance in heavy-duty lifting applications. Manufactured in our advanced forging factories and certified to CE and ISO 9001 standards, our double head lifting anchors offer superior load-bearing capacity, enhanced corrosion resistance, and consistent quality. With a professional production team, strict inspection processes, and faster delivery options, we deliver anchors that meet higher standards for safety, durability, and efficiency in your construction projects.

1 CE ISO 9001 Certified Precast Concrete Double Head Lifting Pin Anchors

2 Shorter Production Cycle

3 3 Times Safety Factor

4 Deliver Faster

5 Comprehensive After Service.

Durable precast concrete double head lifting pin anchors from HULK Metal ensure secure lifting, higher safety factors, and corrosion resistance, meeting CE and ISO 9001 standards for demanding construction applications worldwide.

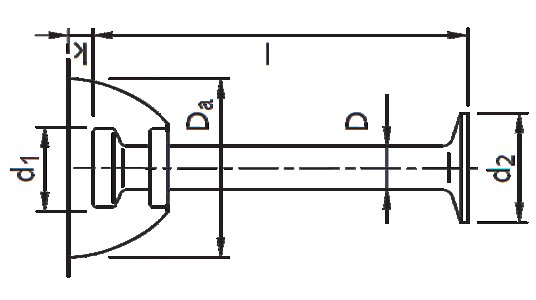

The parameters of precast concrete double head lifting pin anchors include detailed dimensions and Working Load Limits (WLL) to ensure correct selection for your project. HULK Metal provides precise specifications for each size, helping you match anchors to specific lifting requirements. All parameters comply with CE and ISO 9001 standards, ensuring consistency, safety, and compatibility with related lifting systems. Accurate data supports safe handling and optimal performance in precast concrete construction.

| Name | Double Head Lifting Anchor | |||

| Drawings |  | |||

| Material | 20Mn2 / Q345D / CM490 / Stainless Steel / Customizable | |||

| Surface Treatment | Raw Black / Electro-galvanized / Hot-dip Galvanized | |||

| Safety Factor | ≥ 3 | |||

| Certification | ISO9001 / CE | |||

| SWL (tons) | CODE | LENGTH(mm) | D(mm) | WEIGHT(kg/pc) |

| 1.3 | HM-D-013055 | 55 | 10 | 0.063 |

| HM-D-013065 | 65 | 10 | 0.068 | |

| HM-D-013085 | 85 | 10 | 0.08 | |

| HM-D-013120 | 120 | 10 | 0.1 | |

| HM-D-013240 | 240 | 10 | 0.172 | |

| 2.5 | HM-D-025055 | 55 | 14 | 0.14 |

| HM-D-025065 | 65 | 14 | 0.152 | |

| HM-D-025075 | 75 | 14 | 0.164 | |

| HM-D-025085 | 85 | 14 | 0.172 | |

| HM-D-025110 | 110 | 14 | 0.206 | |

| HM-D-025120 | 120 | 14 | 0.215 | |

| HM-D-025140 | 140 | 14 | 0.24 | |

| HM-D-025170 | 170 | 14 | 0.272 | |

| HM-D-025240 | 240 | 14 | 0.35 | |

| 5 | HM-D-050055 | 55 | 20 | 0.316 |

| HM-D-050075 | 75 | 20 | 0.362 | |

| HM-D-050085 | 85 | 20 | 0.385 | |

| HM-D-050120 | 120 | 20 | 0.472 | |

| HM-D-050180 | 180 | 20 | 0.613 | |

| HM-D-050240 | 240 | 20 | 0.755 | |

HULK Metal's precast concrete double head lifting pin anchors are engineered for safe and efficient lifting of precast elements. Each anchor is manufactured to strict CE and ISO 9001 standards, ensuring consistent performance and high load-bearing capacity. With optimized design, superior materials, and precision manufacturing, these anchors provide reliable connection points for lifting systems, improving handling efficiency and reducing risks during transport, installation, and structural positioning in construction projects.

A precast concrete double head lifting pin anchor is a forged steel component embedded into precast concrete elements to facilitate lifting and handling. Its double head design enhances anchoring strength and distributes load more evenly, making it suitable for heavy-duty applications. These anchors work with matching lifting clutches, recess formers, and lifting devices to create a safe, efficient lifting system. Manufactured in compliance with CE and ISO 9001 standards, HULK Metal's anchors are corrosion-resistant, dimensionally precise, and tested for higher safety factors. They are widely used in beams, slabs, panels, and other structural components in precast concrete construction.

Manufactured from high-strength forged steel, the double head lifting pin anchor offers enhanced load distribution and stability. Embedded into precast elements during casting, it provides a secure connection point for lifting operations. Its double head design ensures better stress resistance, reducing the risk of concrete damage during handling. Corrosion-resistant treatments extend service life, while precision manufacturing guarantees dimensional accuracy. Compatible with multiple lifting clutch systems, this anchor is essential for safe, efficient, and repeatable lifting in demanding precast concrete applications.

The lifting clutch is a robust and reusable device designed to connect securely with the heads of the anchor. It allows quick attachment and release during lifting, improving operational efficiency. Manufactured from high-grade steel, it withstands repeated use without compromising strength or safety. The clutch ensures the load is evenly transferred from the anchor to the lifting device, reducing stress on the concrete. Compatible with different anchor sizes, it is a vital component for safe precast element handling.

A recess former creates an accessible pocket in the concrete for the anchor head, enabling easy lifting clutch engagement. Made from durable, reusable materials, it maintains precise dimensions for consistent placement. During casting, it holds the anchor in position and shapes the recess without affecting concrete strength. Its design prevents concrete from covering the anchor head, ensuring fast connection during lifting. The recess former can be tailored to specific project needs, enhancing lifting speed and operational safety.

Lifting devices include cranes, hoists, or specialized rigging equipment used to move precast elements. They work with the lifting clutch and anchor to transfer loads safely from the concrete to the crane hook. Built for heavy-duty use, these devices ensure stability and control during lifting. Properly selected lifting devices reduce the risk of accidents, improve handling efficiency, and extend the service life of lifting accessories. They are an essential link between the precast element and the construction site's lifting system.

The double head lifting pin anchor is embedded in the precast element during casting. After curing, a lifting clutch engages with the anchor heads through the recess formed. The lifting device then applies force, transferring load safely from the concrete to the anchor. This design ensures stable load distribution, minimizing stress points in the concrete and preventing damage during handling.

These anchors are widely used in precast beams, wall panels, slabs, stairs, and structural components. They are ideal for projects requiring frequent lifting and precise placement of heavy concrete elements. Their high load capacity, reliability, and quick connection system make them suitable for construction, infrastructure, and industrial precast projects.

High load capacity with triple safety factor.

CE and ISO 9001 certified for quality assurance.

Corrosion-resistant surface treatments extend service life.

Shorter production and delivery cycles.

Compatible with various lifting clutches and systems.

Reliable performance reduces downtime and handling risks.

We analyze your drawings, specifications, and lifting needs to design a tailored production solution, ensuring each double head lifting pin anchor meets your project's safety, performance, and dimensional requirements from the start.

We source certified high-strength steel and conduct chemical composition and mechanical property tests to guarantee durability, load capacity, and compliance with CE and ISO 9001 standards before production begins.

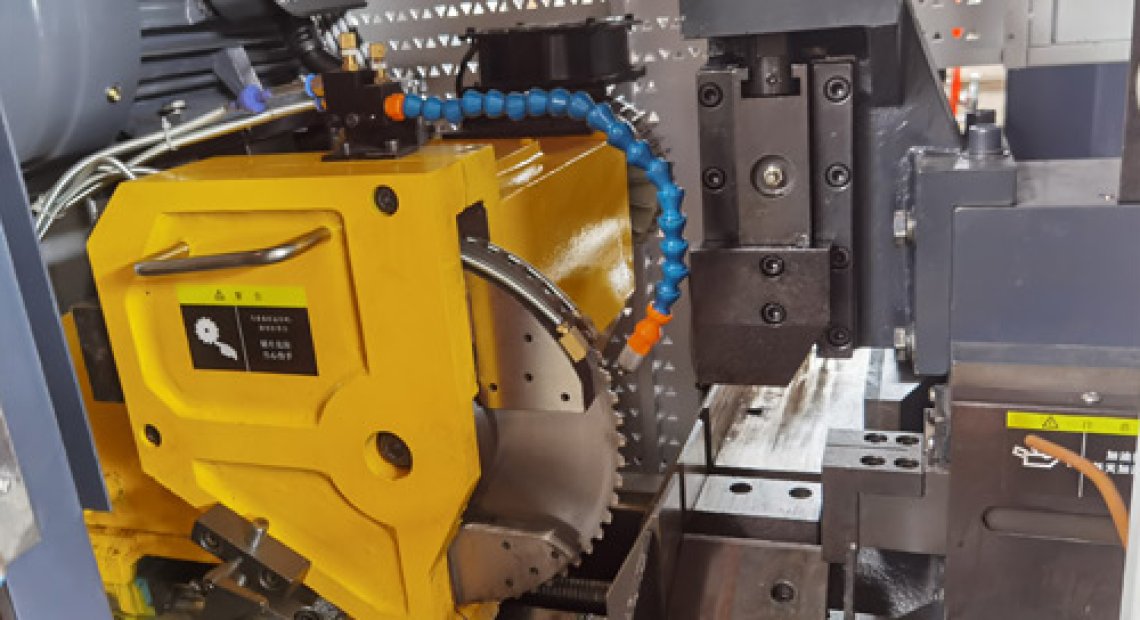

Steel bars are cut to precise lengths using advanced cutting machines, ensuring dimensional accuracy, reducing material waste, and preparing them for the forging process.

Steel pieces are heated to optimal forging temperature, enhancing malleability and ensuring the material's grain structure supports maximum strength after forming.

Anchors are forged using high-pressure equipment to form precise shapes, achieving superior mechanical strength and consistent double head geometry.

Forged anchors undergo dimensional checks and surface inspections to identify any defects before moving to the finishing stage.

Anchors are deburred, edges smoothed, and surfaces refined to ensure safe handling and professional appearance.

We apply galvanizing, hot-dip galvanizing, or custom coatings for corrosion protection and longer service life in demanding environments.

Finished anchors are load tested, checked for coating quality, and verified against customer specifications before packaging.

Anchors are securely packaged to prevent damage, then shipped via the most efficient and cost-effective route for timely delivery.

We provide ongoing technical support, quick solutions to product issues, and guidance to ensure optimal use of your lifting anchors.

High-strength forged steel with protective surface treatments.

A minimum of 3 times the Working Load Limit.

Yes, all anchors meet CE and ISO 9001 standards.

Yes, we can produce according to your drawings or samples.

Electrogalvanizing, hot-dip galvanizing, or as specified.

Shorter production cycles with flexible shipping options.

Yes, compatible lifting clutches are available.

Anchors are embedded permanently; lifting clutches are reusable.

Construction, infrastructure, and industrial precast projects.

Yes, we perform tensile and break tests before shipment.

HULK Metal applies a strict quality control process to every precast concrete double head lifting pin anchor we produce. From dimensional accuracy checks to tensile strength testing, every stage ensures compliance with CE and ISO 9001 standards. Our QC team monitors production continuously, performing multiple inspections before shipment to guarantee safety, reliability, and consistency. This commitment ensures you receive lifting anchors that meet higher safety factors and perform dependably in demanding precast applications.

We measure each anchor's dimensions with precision instruments to ensure conformity with drawings and tolerance requirements, preventing installation issues and ensuring compatibility with lifting clutches and recess formers.

Anchors undergo tensile tests to verify load capacity meets or exceeds the required safety factor, ensuring reliable lifting performance in heavy-duty precast concrete applications.

Before delivery, we conduct a final inspection covering appearance, dimensions, coating quality, and packaging to confirm all anchors meet customer and international quality standards.

We count and verify all packaged anchors against the order quantity, ensuring accuracy and preventing supply delays for your precast concrete project schedule.

HULK Metal works with specialized forging factories, galvanizing factories, and a fully equipped QC center to manufacture high-quality double head lifting pin anchors. Each partner factory is audited for capacity, quality control, and compliance with CE and ISO 9001 standards. By integrating advanced machinery, experienced technicians, and rigorous testing, we ensure every anchor is produced, coated, and inspected to the highest standards, ready to perform in demanding precast concrete lifting environments.

Our forging factory is equipped with advanced heating systems, high-tonnage forging presses, and precision cutting equipment to produce double head lifting pin anchors with exceptional strength and accuracy. Skilled workers ensure consistent forging quality, while automated processes improve efficiency and repeatability. The factory follows strict ISO 9001 quality management procedures, with in-process inspections to detect and correct defects immediately. This controlled environment ensures each anchor meets load capacity requirements, dimensional specifications, and surface finish standards before moving to the next production stage.

Our QC center is equipped with advanced testing instruments, including tensile testing machines, hardness testers, and coating thickness gauges. Trained inspectors follow detailed protocols to check every double head lifting pin anchor for compliance with dimensional tolerances, load capacity, and coating requirements. The center also performs random destructive testing to verify safety factors, ensuring anchors exceed project specifications. With meticulous documentation and traceability, the QC center ensures each shipment meets the highest standards before leaving the production facility.

The galvanizing factory specializes in applying protective coatings that enhance the corrosion resistance of our double-head lifting pin anchors. Whether electro galvanizing, hot-dip galvanizing, or custom coatings, the process is carefully controlled to achieve uniform thickness and strong adhesion. Every surface treatment batch undergoes adhesion and thickness testing to ensure long-term durability, even in harsh environments. The factory meets environmental protection regulations and maintains strict cleanliness standards to guarantee coating consistency and quality for every anchor produced.

Choosing HULK Metal means getting precast concrete double head lifting pin anchors manufactured to higher safety, strength, and durability standards. We combine certified materials, advanced forging processes, and strict multi-stage quality inspections to deliver reliable products with shorter lead times. Our experienced team tailors production to your specifications, ensures superior corrosion resistance, and provides comprehensive technical and after-sales support, giving you a dependable lifting solution for even the most demanding precast construction projects.

You will get the double-head lifting anchor with higher standard certification. HULK has a more professional production team and advanced production line, which can produce in strict accordance with ISO9001. Our quality inspection team can track the production of the order according to your requirements, and we will carry out more than three times the tensile test or break test according to the stress of the product.

You will get the double head lifting anchor with a shorter production cycle. HULK's technical team will plan a production solution, mold, and process samples for you according to the drawings and product requirements you provide. You can keep abreast of production dynamics or participate in it through solutions and pictures, videos, and even video calls provided by us.

You will get the double head lifting anchor with more corrosion resistance. HULK will choose a more suitable surface treatment factory for you according to your requirements. Every manufacturer that cooperates with HULK needs to pass our strict assessment. The plating of your product will be thicker, more uniform, and more wear-resistant. Regardless of whether your product is electroplated or hot-dip galvanized or non galvanized, we will add an anti-corrosion layer to make it easier for you to store and use your product.

You can get the double head lifting anchor with shorter delivery cycle. According to your country and region, HULK will combine sea, air, and land transportation to plan a more suitable freight route in a faster and more cost-effective direction. We will also provide you with free warehousing services. Add some cushioning capacity to your inventory.

You can enjoy the comprehensive after-service when buying HULK products. HULK has established an after-sales service team that integrates production support, technical support, procurement support, quality inspection support, freight consulting support, and other support. At HULK, no matter what problem you have, as long as it involves double head lifting anchor, it can be quickly solved.

Here you can find in-depth articles about precast concrete double head lifting pin anchors, covering their design, manufacturing process, applications, and best practices for safe lifting. These resources provide valuable insights into choosing the right anchor, using compatible lifting systems, and ensuring compliance with safety standards. Whether you're a precast manufacturer, contractor, or engineer, these articles offer practical knowledge to help you improve lifting efficiency, reduce risks, and maximize the service life of your lifting equipment.

HULK Metal also offers a wide range of precast concrete accessories to meet different lifting, fixing, and reinforcement needs. Our product range includes spherical head lifting anchors, lifting clutches, recess formers, wire rope lifting loops, spread anchors, and more. Each accessory is manufactured to high safety and quality standards, ensuring durability, reliability, and compatibility with your precast elements. With professional technical support and strict quality control, we provide complete solutions to improve the safety and efficiency of your precast concrete projects.

Precast concrete lifting anchors are accessories designed specifically for the lifting of precast concrete elements. It includes lifting pin anchors (as know as dog bone anchors, spherical head lifting anchors), double head lifting anchors, utility anchors, etc. It needs to be embedded in precast concrete elements, fixed with a recess former, and a recess is created in the fixed position to accommodate the lifting clutch. They can be used in many elements such as: concrete trenches, culverts, stairs, pipes, panels, etc.

Lifting & Fixing Sockets, also commonly called Lifting & Fixing Inserts, are accessories designed for the lifting and anchoring of precast concrete elements. They are pre-buried in specific locations in the concrete to provide lifting points or connection holes for lifting or connecting other elements. With the development of the quick-install concrete industry, many types have been derived. It generally consists of two parts: a sleeve part and a stress transfer part. Depending on the different stress transfer parts, dozens of products can be derived.

Precast concrete spread anchors are made of high-performance alloy steel plates and are designed to be embedded in precast concrete elements to provide accessories for lifting points. Its international standard is CE certification. It needs to undergo strict tensile performance sampling inspection—using a tensile force of 3 times or even higher safety factor until it is broken. There are many types of it, and when using it, you need to consider the shape, thickness, lifting point location, weight and other factors of the precast concrete elements.

HULK Metal has been engaged in the production and sales of precast concrete lifting clutch since 2006, and has accumulated rich experience. We have integrated a complete supply chain and formed a professional team to provide better products and services. Our lifting clutch has passed the CE certification and can pass the destructive test with a 5-fold safety factor. Here you can learn about our product range, production capacity, and service capabilities.

HULK Metal offers a wide range of G60, G70, and G80 strength lifting hooks with a well-established supply chain. We have an advanced forging factory and integrated assembly line production. The quality of lifting hooks will be more guaranteed, and we can provide electro-galvanizing, hot-dip galvanizing, and powder coating—three surface treatments. We strictly implement ISO 9001 standard management to provide you with higher quality products and services. You can contact us at any time to visit the factory to understand our production capacity and service capabilities, and then hand over the order to us after you are satisfied.

Recess formers are used to place lifting anchors, spread anchors, and other accessories that need to be pre-buried in precast concrete elements. The recess they leave is for the lifting clutch to connect with lifting anchors or spread anchors. We offer a full range of standard recess formers and OEM services for special requirements.

Precast concrete magnets are one of HULK Metal's main products. They are recognized by customers for their high quality and reasonable price. Precast concrete magnets use high-performance and durable NdFeB alloy magnets. Advanced technology effectively improves production efficiency and reduces costs while ensuring its quality. We provide quality assurance services. You can purchase them with confidence.

HULK Metal also specializes in OEM services for cast-in-channel, T-bolts, wire rope boxes, stone support brackets, and other accessories. Cast in channel can be made of cold-rolled steel, hot-rolled steel, and stainless steel. T bolts are made of carbon steel, alloy steel, and stainless steel. Our wire rope box only has one wire rope, and stone support brackets only accept OEM services. We will develop a perfect solution according to your requirements to ensure that the delivery time, quality, and price can meet your requirements.

HULK Metal offers high-quality foot anchors designed for secure lifting of precast concrete elements. Our CE and ISO 9001 certified lifting pin anchors ensure a threefold safety factor, shorter production cycles, and prompt delivery.

HULK Metal has supplied tens of millions of Lifting Pin Anchors ranging from 1.3 tons to 32 tons to hundreds of buyers around the world. We have a full range of products and a complete supply chain to provide you with quality services. We provide quality assurance services. Please feel free to inquire.

HULK Metal manufactures lifting pin (dog bone) anchors with higher standards to meet demanding precast concrete lifting needs. We offer complete OEM solutions, from design and production to surface treatment and delivery, ensuring each anchor provides excellent strength, corrosion resistance, and compatibility with various lifting systems.

HULK Metal stands out as a leading manufacturer of lifting eye anchors, specializing in precast concrete lifting eye anchors that meet stringent CE certification with a 3 times safety factor.

Durable precast concrete double head lifting pin anchors from HULK Metal ensure secure lifting, higher safety factors, and corrosion resistance, meeting CE and ISO 9001 standards for demanding construction applications worldwide.

Durable, CE-certified spherical head lifting anchors from HULK Metal offer reliable load capacity and corrosion resistance, ensuring safe, efficient lifting for precast concrete projects with fast delivery and quality assurance.

Lifting Pins for Precast Concrete supplied by HULK Metal are CE certified. We can supply Lifting Pins that can pass the tensile test of 3 times the safety factor and strictly implement the IS0 9001 standard to provide high-quality services.

Short Wavy Tail Anchor is a compact, high-strength lifting solution for precast concrete elements. Its wavy rebar tail ensures even load distribution, prevents concrete cracking, and connects securely with threaded sockets or lifting inserts for safe, efficient operations.

Wavy tail anchor is made of high-performance steel pipe and rebar extrusion after bending. Its SWL range is between 0.5 and 8.0 tons. There are two thread standards, M and RD.

HULK Metal is a well-known supplier in China, providing high-quality and cost-effective Precast Lifting Thread Insert. With a complete supply chain and a professional team, we have provided flat end insert, solid rod insert, Tubular insert and others to global customers. We provide complete QA services. Looking Forward Your Inquiry.

HULK Metal is one of the high-quality Flat End Lifting Insert suppliers in China. In order to provide better services and products, we have integrated a complete supply chain. We strictly implement ISO 9001 management, and after years of development, we can now supply a full range of CE certified Flat End Lifting Insert.

Solid Rod Lifting Inserts supplied by HULK Metal have passed the CE certification. They can pass the tensile test with 3 times the safety factor. We strictly implement ISO 9001 standards to manage the entire supply chain to ensure that we can provide you with better Solid Rod Lifting Inserts and services.

Solid rod lifting and fixing sockets embed into precast concrete for secure threaded connections. Crafted from sturdy steel rods, one end features tapping for attachments, while the other includes a hole for rebar passage, enhancing structural integrity.

The combi lifting socket combines a lifting pin anchor and threaded socket, providing a strong, secure connection for lifting and handling precast concrete elements in construction and infrastructure projects.

HULK Metal's Flat End Fixing Socket with Cross Pin integrates a robust cross bar to improve load stability. Manufactured to CE and ISO 9001 standards, it ensures exceptional strength, corrosion resistance, and reliability for various precast concrete lifting applications.

Fixing sockets with bent ends, also known as fixing inserts with bent ends, is essential for anchoring in precast concrete. These sockets provide robust points for fixing elements, featuring a bent design that enhances grip and stability.

Tubular Lifting Insert supplied by HULK Metal has passed CE certification. Tubular Lifting Insert can pass the 3 times safety factor tensile test, and each batch of goods has a comprehensive test report.

HULK Metal can provide you with RD and M standard 12-45 thread, SWL 0.5 to 8.0tons of Long Wavy Lifting Insert. Its international general standard is CE, which needs to pass the 3 times safety factor tensile force test.

HULK Metal manufactures durable solid rod fixing sockets with cross pins and inserts with cross bars for precast concrete. CE and ISO 9001 certified, with high safety factors and quick delivery for bulk orders.

HULK Metal offers premium flat end lifting sockets designed for safe and efficient handling of precast concrete elements. Manufactured from high-strength alloy steel and certified to CE and ISO 9001 standards, these lifting inserts provide exceptional load capacity and corrosion resistance.

HULK Metal's tubular lifting sockets, made from high-grade steel or stainless steel, provide secure threaded connections in precast concrete. CE certified and precision manufactured, they ensure reliable lifting performance, excellent durability, and meet strict safety requirements for diverse construction applications.

The Long Wavy Lifting Socket combines a threaded steel pipe with a wavy-tail rebar to achieve deeper stress transfer in precast concrete. Designed for heavy-duty lifting, it meets CE and ISO 9001 standards and ensures a 4 times safety factor.

Q345/20#/Stainless steel/Others

Galvanized/Black

8~52

≥3

Flat plate lifting sockets embed into precast concrete for secure lifting points. The design includes a threaded end for clutch attachment and a broad base for load distribution, available in galvanized finishes for added durability.

Flat end fixing sockets, also known as flat end fixing inserts, anchor securely into precast concrete for fixing. Made from sturdy steel, they feature a flat end for easy installation and a threaded interior for bolts.

Plate spread anchors from HULK Metal feature a welded steel plate and head design, embedded in concrete for edge lifting. Available in various sizes with galvanized options, they support loads up to 10 tons safely.

Unilateral erection anchors serve as specialized lifting inserts for precast concrete, designed for one-sided loading during element erection. They integrate with ring clutches and recess formers, providing stable anchor points that enhance safety and reduce panel stress in construction applications.

HULK Metal supplies flat foot anchors crafted from premium alloys for secure lifting in precast concrete projects worldwide.

HULK Metal stands as a reliable erection anchor supplier in China, delivering high-standard products for precast concrete lifting. Our anchors ensure secure handling with superior strength and corrosion resistance, backed by comprehensive production support for bulk orders.

HULK Metal supplies CE and ISO9001 certified spread anchors with reliable safety factors, faster delivery, and professional support. Choose our spread anchors for superior quality and complete precast lifting solutions.

HULK Metal delivers high-quality two-hole anchors, designed for secure lifting of precast concrete elements. Certified with CE and ISO 9001, our anchors ensure safety, durability, and efficiency.

Ring Clutch supplied by HULK Metal is CE certified and can pass the tensile test with a safety factor of 5. We have integrated a complete supply chain and formed a complete team to provide better products and services.

HULK Metal's Precast Concrete Lifting Lugs, also known as Lifting Clutches or Lifting Eyes, are precision-engineered for heavy-duty lifting. Manufactured with high-strength materials, they ensure safety, durability, and efficiency in precast concrete lifting applications worldwide.

High-quality dog bone lifting eye with CE and ISO9001 certification. Strong, safe, and durable for precast concrete lifting. Shorter production cycle and faster delivery from trusted Chinese supplier HULK Metal.

HULK Metal supplies CE and ISO 9001 certified lifting clutch for pin anchor with 5 times safety factors, shorter production cycles, and complete after-sales support for global precast concrete projects.

Dog Bone Lifting Eye With Chain supplied by HULK Metal can pass the 5 times safety factor test and has been CE certified. We can provide 1.3 to 20 tons load groups.

Ring Clutch supplied by HULK Metal is CE certified and can pass the tensile test with a safety factor of 5. We have integrated a complete supply chain and formed a complete team to provide better products and services.

Precast Concrete Lifting Eyes supplied by HULK Metal has passed CE and ISO 9001 Certified and can passed 5 times safety factor testing. HULK Metal is an experienced manufacturer in China. Looking forward your inquire.

Q345/35CrMo/Others

Galvanized/Black/Powder-coat

1.3~32.0

≥5

Precision Casting

HULK Metal has a well-established supply chain to provide you with a full range of Clevis Slip Hooks, such as G43, G70, G80, CE marked, with latch or none, electro-galvanized, hot-dip galvanized or powder coated.

We have provided customers in more than 100 countries and regions around the world with Clevis Grab Hooks with strength standards such as G43 70 80 that can pass 2 to 4 Times Safety Factor detection.

HULK Metal is an experienced eye grab hooks supplier in China. We have integrated a complete supply chain and formed a professional team to provide better products and services. We can provide eye grab hooks with various specifications and surface treatments.

HULK Metal is an experienced supplier in China, providing Eye Slip Hooks in various materials, strengths, certifications, surface treatments and sizes. We have established a complete supply chain to ensure that raw materials, production and delivery are under control to provide higher quality and low-cost lifting hooks.

Anchor Recess is an essential component for positioning lifting anchors accurately in precast concrete elements. HULK Metal supplies Anchor Recess in multiple materials and configurations to match different lifting systems and production methods.

HULK Metal provides high-quality Rubber Recess Former for precast concrete lifting systems. They are used with Pin Anchor Recess Former and Spread Anchor Recess Former, ensuring precise recess shaping, shorter production cycles, and faster delivery.

HULK Metal supplies durable lifting pin anchor recess former for precast concrete elements, offering sizes from 1.3 to 32 tons with CE and ISO 9001 certification. Get shorter cycles and comprehensive support for bulk orders.

HULK Metal can provide a variety of precast magnetic formers. With higher quality and a more affordable price, it is your best choice.

The Spread Anchor Rubber Recess Former is made of durable rubber with a reinforced rear metal plate. It is designed for fixing spread anchors in precast concrete, ensuring accurate positioning, easy demolding, and reliable lifting performance.

As one of the excellent magnetic recess former suppliers in China, HULK Metal has advanced factories and perfect supply chain to provide you with high-quality products and services.

HULK Metal can provide CE-certified magnets for precast lifting and fixing inserts or sockets. Our factory has advanced machining equipment, laser cutting machines, and assembly lines, which can more efficiently complete CE-certified precast lifting fixing insert socket magnet with a higher pass rate.

HULK Metal's Electrical Box Fixed Magnets feature a durable rubber body combined with strong NdFeB magnets, ensuring reliable fixation of electrical boxes in precast concrete. These magnets are customizable in shape, size, and finish, providing flexibility for bulk orders.

Our Shuttering Magnets for Formwork are designed for precast concrete production, offering reusable and stable fixing solutions. They support different mold sizes and deliver better cost-efficiency for large-scale construction projects.

Our Embedded Corrugated Pipe Fixed Magnet combines premium steel housing with powerful magnets to ensure strong fixation during precast concrete production. It reduces installation time, improves efficiency, and provides consistent performance across different applications, helping customers achieve safer and more reliable concrete elements.

Steel Embed Plates are essential components used to create strong, reliable connection points within precast concrete structures. As an experienced manufacturer in China, HULK Metal supplies Concrete Embed Plates with stable quality, flexible customization, and consistent production capacity.

Cast In Channel T Bolts from HULK Metal are precision-forged using high-performance alloy steel or stainless steel. Surface treatments, including electro-galvanizing or hot-dip galvanizing, enhance rust resistance, making them reliable for precast concrete connections in construction and infrastructure projects.

HALFEN Anchor Channels from HULK Metal offer superior quality, CE and ISO certified standards, and five times safety factor. Our fast production and delivery, combined with professional after-sales support, make bulk purchasing simple and reliable.

Name Wire Loop Box Precast Concrete Accessories

Molds Full Range Moulds

Materials Wire Rope / Steel Plate / Customized

SL(mm)±10 60 / 80 / 100 / 120 /140

Our Cast in Channel offers superior strength, certified safety, and flexible application for precast construction. Manufactured with advanced processes, it guarantees durability, easier installation, and faster delivery. HULK Metal supports bulk buyers with full technical service and reliable after-sales support.

Our concrete screw bolts are designed for reliable installation without expansion anchors. Galvanized concrete screws provide superior corrosion resistance, making them ideal for indoor and outdoor use. HULK Metal offers diverse sizes, surface treatments, and customized solutions to match your needs.

Q345/20#/Stainless steel/Others

Galvanized

0.8~25.0

6~32

≥3

HULK Metal lifting loops are made from alloy or carbon steel, precision-threaded, and electro-galvanized for corrosion resistance. Designed for use with lifting sockets, they ensure safe, reliable handling of precast concrete components with a ≥4 safety factor.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU