HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings. From engine housings to chassis brackets, we ensure tight tolerances, durable finishes, and on-time delivery. With in-house QC, technical support, and logistics, we simplify global sourcing — so you get reliable parts, fewer headaches, and better margins. Your drawing. Our process. Perfectly executed.

1.ISO 9001 certified casting factory

2.Professional technical team to provide support

3.Finalize your order faster

4.Perfect quality assurance service.

5.Finalize Casting Motorcycle Parts at a lower price.

We manufacture Casting Motorcycle Parts via OEM production based strictly on customer drawings. Whether sand casting for rugged frames or die casting for sleek housings, we handle iron, steel, stainless, or aluminum with equal precision. Surface treatments, machining, packaging — all customized. No design work — just flawless execution of what you specify. Reliable. Repeatable. Ready when you are.

Our Casting Motorcycle Parts cover engine blocks, transmission cases, brake calipers, swingarms, and decorative trim — all made per your CAD or print. Materials include ductile iron, carbon steel, stainless, and die-cast aluminum alloys. Processes: sand, investment, lost foam, or high-pressure die casting. Post-machining, surface prep, and custom packaging included. Full dimensional + metallurgical testing. Global shipping. Lifetime QA backing. No minimums too complex — if it’s metal and castable, we’ll make it right.

Name | Casting Motorcycle Parts |

Manufacturing Methods | Manufacturing According to Drawings |

Raw Materials | Iron, Steel, SS (Stainless Steel), Die Casting Aluminum |

Process | Casting: Sand Casting, Investment Casting, Lost Foam Casting, Die Casting CNC Machining: Turning, milling, polishing, grinding, drilling, and reaming, and so on Packaging, Delivery, After Service. |

Surface Treatment | Sandblasting / Shot Blasting / Powder Coating / Galvanized / Customized |

Types | Engine Casting Parts,Transmission and Powertrain Parts,Chassis and Structural Casting Parts,Brake and Suspension Casting Parts,Appearance and Accessory Casting Parts. |

Surface Treatment | Powder Coating,Sandblasting, Raw Black / Customized |

Test Content & Data | 1.Chemical Composition; 2. Mechanical Properties; 3. Inspection of appearance, size, shape, and position tolerance; 4. Surface Quality; |

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

Delivery Method | Sea / Air / Land |

Quality Assurance | Life Long |

From material selection to final inspection, every step in producing Casting Motorcycle Parts is engineered for precision, durability, and performance. We match the right process — sand, die, investment, or lost foam — to your design and volume. Backed by certified factories, strict QC, and full OEM support, we turn your drawings into ride-ready components — faster, stronger, and more cost-efficient than you thought possible.

Casting motorcycle parts means shaping molten metal into high-strength, precision components — from engine cases and swingarms to brake calipers and footpegs — using molds instead of machining everything from solid blocks. It’s the smart way to produce complex shapes with internal cavities, thin walls, or curved surfaces that would be too costly or impossible to cut from billet. At HULK Metal, we specialize in two dominant methods for bike parts: sand casting and die casting. Sand casting gives you rugged, cost-effective parts in iron or aluminum — ideal for low-to-medium volumes or heavier structural pieces like triple clamps or rear subframes. Die casting? That’s where speed, surface finish, and repeatability shine — perfect for high-volume runs of transmission covers, heat sinks, or decorative trim in aluminum alloys. Both processes start with your drawing. Both end with fully inspected, ready-to-assemble parts. And both are backed by our technical team who’ll help you pick the right method, tweak the design for manufacturability, and lock in the best price without compromising performance.

Sand casting motorcycle parts offers unmatched flexibility for prototypes or mid-volume production. Using compacted sand molds, we pour molten aluminum, iron, or steel to form thick-walled, durable components like engine mounts, frame lugs, or custom exhaust manifolds. It’s forgiving on complex geometries and budget-friendly for short runs.

Die casting motorcycle parts, by contrast, uses high-pressure injection into hardened steel dies — delivering ultra-smooth surfaces, tight tolerances, and blistering production speeds. Think throttle bodies, ignition housings, or heat-dissipating fins where consistency matters. Aluminum dominates here for its lightweight strength. While tooling costs run higher upfront, per-part prices plummet at scale.

We guide you through material selection, wall thickness optimization, draft angles, and gating design — ensuring your part not only casts cleanly but performs under real-world vibration, heat, and stress. Whether you need one-offs or ten thousand, we’ve got the process — and the factory — to match.

From reading your drawing to shipping finished goods, we manage every step: selecting the right process, building and testing molds, sourcing certified metals, running full production batches, inspecting dimensions and metallurgy, packing securely, and standing by for returns or restocking. No detail overlooked.

Before melting any metal, we analyze your part’s function, volume, material, and tolerance needs. Thick, heavy-duty brackets? Likely sand cast. Thin, high-precision housings in big batches? Die casting wins. Our engineers compare lead times, tooling costs, and mechanical properties — then recommend the optimal path so you get performance without overpaying.

Using your CAD file, we engineer molds that release cleanly, fill evenly, and cool without warping. For die casting, that means CNC-machined steel cavities with precise ejector systems. For sand, it’s pattern plates and core boxes. We test-run samples, tweak gating or vents if needed — zero surprises at full production.

We source aluminum ingots, ductile iron, or stainless steel from pre-vetted mills — each batch comes with mill certs. Before pouring, we verify chemistry via spectrometer and check grain structure. No off-spec metal touches your order. Consistent input = consistent output. You get what your drawing calls for — nothing less.

Once molds are locked and materials approved, we ramp to full volume. Automated lines handle die casting cycles; skilled crews manage sand mold assembly and pour timing. Production logs track every shift, furnace batch, and cavity ID — traceability built in. High output doesn’t mean rushed output. We pace for perfection.

Every shipment undergoes dimensional checks with CMMs and gauges, visual defect scans, hardness tests, and — when required — X-ray or dye penetrant inspection. We compare against your print’s GD&T callouts. If a part misses spec, it’s quarantined and replaced before boxing. Final reports? Included with every PO. No exceptions.

Parts are cleaned, coated if specified (powder, blast, zinc), then packed to survive global transit — foam-lined crates, rust-inhibited wraps, or bulk bins as needed. We label by PO and SKU. Pick your lane: FOB Ningbo, DDP to your dock, air freight for rush jobs. Tracking updates sent automatically. Damage? We reship.

Got a field failure? Short shipment? Surface defect? Email your PM — we respond in 24 hours. Returns, exchanges, or restocking handled fast, no finger-pointing. We keep reserve capacity for re-runs and archive molds for repeat orders. Your satisfaction isn’t a phase — it’s our policy. Ride easy.

From engine blocks to brake calipers, we cast every major motorcycle component. Each category — powertrain, chassis, suspension, or trim — is engineered for strength, precision, and performance. All made to your print. No design guesswork. Just flawless metal, formed right.

Category | Example Products | Description |

Engine Casting Parts | Crankcases, cylinder heads, clutch housings, oil pump bodies, camshaft carriers | These are the heart of your bike — and they demand zero tolerance for error. We cast them in aluminum or iron using die or sand methods, depending on volume and stress load. Internal oil galleries, threaded inserts, and heat-treated surfaces are standard. Post-machining ensures perfect sealing faces and bearing fits. Whether you’re building 50 custom café racers or 50,000 commuters, our engine parts deliver leak-free, vibration-resistant performance straight off the line. |

Transmission & Powertrain Parts | Gearbox housings, primary drive covers, sprocket carriers, shift drum assemblies, torque arms | Precision here means smooth shifting and no gear whine. We use die casting for high-volume aluminum cases with thin walls and complex internal ribs. Sand casting handles heavier iron components like torque arms. All parts undergo full CNC machining for bearing bores and spline interfaces. We inspect gear mesh clearance and alignment datums so your transmission bolts in ready to rip — no shimming, no rework. Built for abuse, finished for perfection. |

Chassis & Structural Casting Parts | Triple trees, swingarms, frame lugs, subframe brackets, footpeg mounts | These carry the load — literally. Cast in ductile iron or high-strength aluminum, they’re designed to handle cornering Gs, pothole impacts, and rider weight without flex or fatigue. Sand casting dominates here for its toughness and cost efficiency on medium runs. Critical mounting points are machined post-cast for bolt-on accuracy. We test wall thickness uniformity and perform dye penetrant checks on weld zones. Whether it’s a dirt bike or a tourer, your chassis deserves rock-solid foundations. |

Brake & Suspension Casting Parts | Caliper bodies, master cylinders, fork lowers, linkage arms, reservoir mounts | Safety-critical doesn’t mean slow production. Die-cast aluminum gives us the surface finish and dimensional stability needed for hydraulic seals and piston bores. Internal passages are cored cleanly; external ribs add stiffness without weight. Every caliper body gets pressure-tested before leaving the factory. Suspension linkages are shot-peened for fatigue resistance. We don’t cut corners — because your brakes and suspension shouldn’t either. Smooth action. Zero leaks. Total confidence. |

Appearance & Accessory Casting Parts | Engine covers, side panels, handlebar clamps, radiator shrouds, custom badges | Looks matter — especially when they’re bolted to a show bike or premium commuter. We use high-gloss die casting for mirror-finish aluminum trim, then apply powder coat, anodizing, or chroming as specified. Intricate logos? Undercut details? No problem — lost foam or investment casting handles the curves. These parts aren’t just decorative; they’re functional too — heat-resistant, UV-stable, and impact-tested. Bolt-on beauty that lasts longer than the season. |

Finish isn’t just cosmetic — it’s corrosion resistance, wear protection, and brand identity. We offer electrochemical, mechanical, chemical, and thermal treatments tailored to your part’s function and environment. From raw industrial to showroom gloss — we’ve got the process, and the proof.

Treatment Type | Methods Offered | Description |

Electrochemical | Anodizing (clear/color), hardcoat anodizing, electroplating (zinc, nickel, chrome) | Electrochemical finishes build durable oxide or metal layers directly onto aluminum or steel. Hardcoat anodizing adds wear resistance for shift levers or footpegs. Color anodizing lets you brand parts without paint. Zinc plating protects steel brackets from rust; chrome gives calipers that deep showroom shine. All processes follow RoHS standards. Layer thickness is measured and logged. Salt spray tested up to 500+ hours. Functional protection meets visual pop — no flaking, no fading, no shortcuts. |

Chemical | Passivation (for SS), phosphating, chromate conversion, black oxide | Chemical baths alter the surface at a molecular level — no electricity required. Passivation removes free iron from stainless parts to maximize corrosion resistance. Phosphating preps steel for paint adhesion or oil retention. Chromate conversion gives aluminum a gold or clear iridescent film that resists white rust. Black oxide delivers that stealthy, non-reflective gunmetal look popular on performance bikes. All chemistries are controlled, rinsed, and neutralized — safe for assembly, safe for riders. |

Electrostatic / Powder Coating | Epoxy, polyester, hybrid powders; matte, gloss, textured, metallic finishes | Powder coating isn’t paint — it’s charged particles baked into a seamless, chip-resistant shell. Ideal for engine covers, brackets, or exposed chassis parts. We mask critical mating surfaces and cure at precise temps for max adhesion. UV-stable formulas won’t chalk or fade. Textured grips? Candy apple red? Satin black? Done. Thicker than liquid paint, tougher than plating. And since it’s solvent-free, it’s as green as it is gorgeous. Your color. Your texture. Locked in for life. |

Mechanical | Shot blasting, sandblasting, vibratory finishing, polishing, brushing | Sometimes you want raw metal — but refined. Shot blasting peens surfaces for fatigue resistance on swingarms. Sandblasting creates uniform matte textures before painting. Vibratory tumbling deburrs intricate castings without damaging edges. Mirror polishing turns aluminum engine covers into jewelry. Brushed finishes give a directional grain that hides scratches. We control media size, pressure, and dwell time so every part gets the exact look and function you specify — not random abrasion. Clean. Consistent. Crafted by hand-equivalent machines. |

Physical / Thermal | laser etching, PVD coating, ceramic coating | Beyond looks — we enhance performance. T6 tempering boosts aluminum’s strength for stressed engine mounts. Laser etching adds permanent serial numbers or logos without ink. PVD (Physical Vapor Deposition) lays down titanium nitride or zirconium coatings for ultra-hard, low-friction surfaces on throttle slides. Ceramic coatings reflect heat on exhaust manifolds. Every thermal cycle is logged and certified. No warping. No soft spots. Just engineered surfaces built to outlast the ride. |

Don’t trust factories that just nod and take your drawing. The right partner questions it — checks wall thickness, draft angles, gating locations. Our engineers catch design-for-manufacturing flaws before tooling starts. That saves you weeks and thousands. Real expertise means speaking GD&T, material specs, and process limits — not just taking orders.

One mold, one machine, one shift won’t cut it for real volume. We tap into multiple casting factories — some specialize in high-pressure die casting runs of 50K+, others handle sand cast prototypes or low-volume custom jobs. Redundancy built in. If one line goes down, your order doesn’t stall. Scale without sacrifice.

ISO 9001 isn’t a wall decoration — it’s our workflow. Every pour logged. Every dimension checked. Every batch traceable. We don’t “spot check” — we inspect per AQL levels you set. Material certs? Surface test reports? All archived. If it fails, we replace it. No debate. No delay. Just accountability.

Raw metal delays kill schedules. We lock in supply with pre-vetted mills — aluminum, ductile iron, stainless — all with mill certs on file. Tooling shops on standby. Packaging partners who know how to crate swingarms without scratching. Even backup freight forwarders. Your production isn’t hostage to someone else’s bottleneck. We own the chain.

From first quote to final delivery, you get one PM — not a rotating door of reps. Sales, engineering, QC, logistics — all under one roof. Need a last-minute revision? Rush inspection report? Customs paperwork? We move as one team. No “that’s not my department.” Just solutions — fast, clear, and in writing.

TT, LC, even DP terms — we adapt to your finance flow. FOB, CIF, DDP — pick your risk level. Need staggered payments against milestones? Done. We don’t force rigid terms because we know global procurement has cashflow realities. Flexibility isn’t a favor — it’s how serious suppliers earn long-term partners.

We’ve shipped motorcycle castings to Germany, California, Brazil, and beyond — by sea, air, or rail. Crate them export-ready. Handle ISF filings. Pre-clear customs. Track every container. Missed a deadline? We expedite at our cost. Your dock date is sacred. Logistics isn’t an afterthought — it’s half the battle won.

Lifetime QA doesn’t mean “good luck.” It means if a caliper cracks or a mount warps in the field, we investigate, replace, and restock — no finger-pointing. We keep mold archives for reorders and failure analysis. You’re not buying parts — you’re buying peace of mind. And that lasts longer than any coating.

We don’t leave quality to chance. Every part passes through our independent QC centers equipped with CMMs, spectrometers, and hardness testers. Inspections follow your print’s GD&T — not random sampling. Material certs, and surface reports are archived per batch. If a part fails, we replace it — no debate. ISO 9001 isn’t paperwork; it’s our daily checklist.

Pricing isn’t guesswork — it’s physics and process. Aluminum die casting costs less per unit at high volumes but needs tooling upfront. Sand casting suits low runs but may need more machining. Tolerance tightness, surface finish, packaging — all factor in. Send us your drawing, and within 24 hours, you’ll get a line-item quote based on real factory costs — no padding, no surprises.

Bigger orders unlock better pricing — that’s simple math. But we also optimize behind the scenes: shared tooling libraries, bulk metal contracts, and process matching (e.g., using lost foam instead of CNC-heavy sand cast). We’ll even suggest design tweaks to reduce machining or scrap. Same quality. Lower cost. Not by cutting corners — by engineering smarter.

MOQ isn’t arbitrary — it’s tied to tooling amortization and setup efficiency. A small zinc die-cast lever might start at 500 pcs; a massive ductile iron swingarm could be 50. Send us your 2D/3D file — we’ll sign an NDA — and within a day, tell you the smartest volume to hit your cost target without overcommitting inventory.

Standard lead time is 30 days from PO to FOB — including mold prep, casting, machining, finishing, and QC. Rush jobs? We’ve delivered prototypes in 14. Large repeat orders? Efficiency gains can shave off days. Complex parts needing multiple processes? Max 45 days — and we’ll flag any risk early. No vague promises. Just tracked timelines.

From raw bead-blasted aluminum to chrome-plated calipers, we match finish to function. Anodizing for wear resistance. Powder coating for brand color. Zinc plating for corrosion control. Ceramic for heat reflection. We don’t just list options — we recommend what works best for your material, environment, and budget. Want textured grip zones or UV-stable gloss? Done. Finish is part of the spec — not an afterthought.

We’ve shipped motorcycle castings to Germany, USA, Brazil, Australia, UAE, Thailand, South Africa, and beyond — over 50 countries total. Sea, air, rail — your choice. DDP, CIF, FOB — your terms. Customs pre-cleared. ISF filed. Damage? We reship. Distance doesn’t dilute our responsibility. Wherever your assembly line is, we’ll get parts there — documented, on time, intact.

Size limits depend on foundry capability — not ours. We’ve cast 2kg throttle bodies and 120kg frame assemblies. Wall thickness, undercuts, core complexity matter more than pure dimensions. Send your CAD — we’ll evaluate manufacturability, suggest process (die/sand/investment), and confirm feasibility within 24 hours. No “too big” or “too complex” — just “how” and “when.”

T/T, LC at sight, DP — standard. Need milestone payments against production phases? We’ll structure it. Prefer EXW, FOB Ningbo, or DDP Los Angeles? Done. We adapt because global procurement isn’t one-size-fits-all. Finance and logistics shouldn’t be friction points — they’re part of the partnership. Tell us your flow; we’ll match it.

We’re your manufacturing partner — not a factory, not a trader. We manage a network of specialized foundries, machine shops, and coating lines — all under our technical and QC oversight. One team handles your project end-to-end: engineers read your prints, buyers lock in metal prices, logisticians track shipments. You get factory-direct quality with enterprise-level coordination — no middlemen, no finger-pointing.

A: You can get a quote in a shorter time by providing the following information at once:

1. 2D and 3D drawings of the Casting Motorcycle Parts. If neither is available, samples can be provided.

2. Quantity.

3. Delivery Terms.

4. Material, surface treatment, tolerance, and weight. If no 3D drawing is available, please provide the following information:

We don’t just read your drawing — we read between the lines. Our technical team asks why you chose that wall thickness, that draft angle, that surface finish. That insight lets us tweak gating, suggest material upgrades, or flag stress points before tooling starts. Better questions = better parts.

Our network isn’t random factories — it’s curated partners who’ve delivered under pressure for years. Foundries with spare capacity. Machining shops with midnight shifts. Packaging crews who know how to protect polished surfaces. When your schedule moves, our chain flexes — without breaking quality or deadlines.

We source aluminum, iron, and stainless from mills we’ve audited personally — not brokers. Every batch gets spectrometer-checked before melting. No “close enough” chemistry. Same specs, tighter pricing, because we buy in bulk and pay on time. Good metal in = reliable parts out. No exceptions.

No cowboy foundries here. Every pour follows a signed-off process sheet — temp, cycle time, mold prep. Operators are trained, not rotated. Production logs track every cavity, every heat number. If a parameter drifts, the line stops. Discipline isn’t expensive — rework is. We choose discipline.

Your print is our checklist. CMMs verify critical datums. Dye penetrant hunts micro-cracks. Hardness testers confirm temper. Reports aren’t optional — they’re bundled with every shipment. Miss one tolerance? We catch it. You shouldn’t have to. Inspection isn’t a phase — it’s woven into every step.

A scratched caliper or dented cover ruins weeks of work. We custom-pack: foam-lined crates for machined faces, VCI wraps for raw steel, compartmentalized bins for small brackets. Pick your INCOTERM — we handle the rest. Damage in transit? We reship same week. Presentation matters — even in a crate.

Received 998 instead of 1,000? One part out of spec? Email your PM — replacements ship in 48 hours. No forms. No blame. Mold archives stay active for years, so repeat runs match perfectly. QA doesn’t end at delivery — it lasts as long as your product does.

Every casting we deliver passes six layers of inspection — from raw metal chemistry to final box count. We don’t sample; we inspect per your AQL. Dimensional checks, surface scans, hardness tests, material certs — all documented. Short shipment? Defect found after delivery? We replace it. Fast. No excuses. Your standards become our checklist — and we check twice.

HULK Metal doesn’t own one factory — we command a network of specialized foundries and support shops across China, each chosen for precision, capacity, and reliability. From high-speed die casting cells to hand-packed sand molds, CNC finishing centers to certified QC labs — your parts move through a seamless, audited chain. No middlemen. No guesswork. Just metal, mastered.

Raw castings become precision components in our partnered CNC shops — equipped with 3-, 4-, and 5-axis mills, lathes, and grinders. We machine sealing faces, bearing bores, threaded inserts, and mounting datums to your exact GD&T. Fixtures are custom-built per part number. In-process probing ensures tolerances stay locked. Coolant filtration and chip evacuation systems keep finishes pristine. Whether it’s a single milled port or 10,000 transmission cases, our machinists turn “almost right” into “bolt-on perfect” — every time.

Our die casting partners run 280T to 1600T cold-chamber machines, optimized for aluminum and zinc alloys used in motorcycle housings, covers, and brackets. High-pressure injection ensures thin walls, crisp details, and near-net shapes that minimize machining. Automated extraction, robotic trimming, and in-line dimensional checks keep cycle times tight and consistency high. Tooling is hardened H13 steel, maintained between runs. Whether you need 500 or 50,000 units, our die casters deliver flash-free, porosity-controlled parts — shot after shot, shift after shift.

Post-cast finishes aren’t an afterthought — they’re engineered into the process. Our coating partners handle everything: anodizing for wear resistance, powder coating for color branding, zinc plating for corrosion control, or ceramic coatings for heat reflection. Blasting media, cure cycles, film thickness — all calibrated to your spec. Racks are custom-designed to avoid masking marks. Salt spray, adhesion, and gloss tests performed per batch. Your brand’s look and your part’s lifespan start here — sealed, protected, and showroom-ready.

Lost foam is our go-to for complex, no-draft geometries — like hollow-frame connectors, internal-duct swingarms, or integrated-bracket assemblies. Polystyrene patterns are coated, buried in sand, then vaporized by molten metal — leaving near-net shapes with zero parting lines. No cores. No molds. Just pure design freedom. Best for aluminum or iron in medium volumes. Surface finish lands between sand and die cast. Ideal when traditional tooling would be too costly or mechanically impossible. We’ve cast what others said couldn’t be cast — cleanly, consistently, affordably.

Our independent quality control centers aren’t inside the foundries — they’re separate, unbiased checkpoints. Equipped with CMMs, spectrometers, hardness testers, and optical comparators, they inspect every production batch — not just samples. Reports include deviation maps, material certs, and pass/fail stamps. Third-party audits? Welcome. Digital records archived for 7+ years. If a part clears our QC, it clears yours. No crossed fingers. No “hopefully.” Just verified, documented, guaranteed compliance — gatekept by experts who answer only to your standards.

When your motorcycle part demands ultra-fine detail — think custom footpeg levers, intricate valve covers, or ornamental trim — investment casting delivers. We work with ISO-certified shell-building shops that use wax patterns, ceramic slurry, and vacuum dewaxing for clean, smooth surfaces. Tolerances hold within ±0.005” on critical features. Minimal machining needed. Perfect for stainless steel or high-temp alloys where appearance and precision matter equally. Batch sizes from prototypes to thousands — all with museum-grade surface definition and structural integrity.

For heavy-duty, low-to-medium volume parts like engine mounts, triple clamps, or custom chassis lugs, our sand casting factories use resin-bonded or green sand systems. Patterns are CNC-machined for accuracy; cores placed by hand for complex internal passages. Pouring temperatures and cooling rates are strictly controlled to avoid warping or shrinkage. Post-shakeout, parts are grit-blasted and dimensionally checked before shipping to machining. Ideal for iron, ductile iron, or aluminum — especially when geometry is too complex or cost-sensitive for die tooling.

Skip the sourcing maze. We deliver complete OEM casting solutions — from print to packaged part — using certified factories, strict QC, and in-house logistics. Faster lead times. Lower costs through smart process matching and bulk material buying. Less hassle with one team managing everything. More confidence with lifetime QA. You focus on your market. We’ll handle the metal.

We don’t just cast — we coordinate the entire journey. Send us your drawing; we handle mold design, material sourcing, production scheduling, CNC machining, surface finishing, custom packaging, and global shipping. No juggling five suppliers or chasing missing certs. One PM. One invoice. One quality standard across sand, die, investment, or lost foam processes. Whether you need 50 prototype swingarms or 50,000 transmission covers, we turn your CAD file into a dock-ready shipment — fully finished, fully inspected, fully accountable.

We cut cost — not corners. Bulk material contracts with mills mean better alloy pricing. Smart process selection (sand vs. die vs. lost foam) avoids over-engineering. Shared tooling libraries reduce upfront NRE. High-yield casting practices minimize scrap. And because we manage the full chain — no broker markups, no hidden freight surprises. You’re not paying for someone else’s inefficiency. Our quotes reflect real factory costs, optimized workflows, and volume leverage. Better price isn’t luck — it’s logistics, locked in.

Our network operates under ISO 9001, but that’s just the baseline. We comply with ASTM, DIN, JIS, and customer-specific automotive or powersports standards. Material certs? Heat treatment logs? PPAP documentation? All provided. Salt spray, tensile, hardness, and dimensional reports archived per batch. Third-party inspections welcome — SGS, TÜV, BV — we’ll schedule them. Whether you’re supplying Harley-Davidson, KTM, or your own brand, our paperwork matches your compliance needs. No “we’ve always done it this way.” Only certified, traceable, audit-ready execution.

While others wait for tooling queues or raw material delays, we move. Pre-vetted foundries mean no trial runs. In-house engineers slash quoting time by reading prints right the first time. Parallel processing — machining while castings cool, coating while QC inspects. Rush orders? We’ve shipped prototype calipers in 14 days from drawing. Standard runs? 3–5 weeks, not 8. Real-time updates. No radio silence. If speed matters — because your assembly line is waiting — we’re built for velocity without compromising an ounce of quality.

Sourcing from China shouldn’t mean midnight calls, language barriers, or QC nightmares. We absorb the complexity. One contact handles tech questions, production updates, inspection photos, and customs docs. Need a revision? We update the mold, not your calendar. Packaging customized? Done. Payment terms flexible? Of course. You get back hours every week — no chasing, no translating, no firefighting. Focus on your customers, your marketing, your growth. Let us sweat the molten metal. That’s the HULK Metal advantage: less stress, more success.

Dive into guides on selecting the right casting method for engine cases, how die-cast aluminum improves heat dissipation in brake calipers, or why sand casting still rules for custom chassis parts. We break down material choices, surface treatments, and real-world failure analysis — all to help you specify smarter, source better, and avoid costly mistakes. Technical, practical, no fluff — just what engineers and buyers need to know.

Beyond bikes, we cast precision components for ATVs, scooters, snowmobiles, and industrial engines — think carburetor bodies, generator housings, suspension knuckles, gear pump casings, and hydraulic manifolds. Also serve agriculture, marine, and construction sectors with durable cast brackets, pulleys, valve bodies, and wear plates. If it’s metal, complex, and needs to be strong, lightweight, or corrosion-resistant — chances are, we’ve already cast it. Send your print. We’ll handle the rest.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

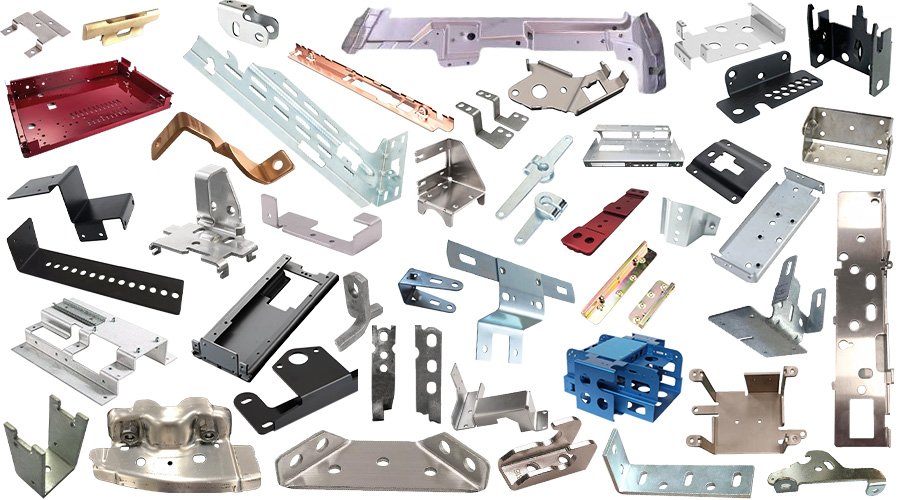

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Precision forging is a near-net-shape manufacturing process that creates high-strength components with superior mechanical properties. At HULK Metal, our OEM services integrate advanced hot and cold die forging with precision CNC machining.

HULK Metal provides a comprehensive OEM solution for high-precision forged steel parts, integrating advanced hot and cold forging factories with elite 5-axis CNC machining.

Description HULK Metal provides a vertically integrated manufacturing solution for Motorcycle Forged Parts, specializing in high-strength components like crankshafts, connecting rods, and triple clamps.

Mining environments demand components with exceptional wear resistance. HULK Metal manufactures custom mining forged parts using premium carbon and alloy steels.

ISO 9001-certified metal forging factory. The technical team supports every phase—from print review to process optimization. Faster turnaround without sacrificing accuracy. Full QA with returns/rework guarantee.

Forged gear blanks provide higher strength, better grain flow, and improved fatigue resistance compared with cut gears.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU