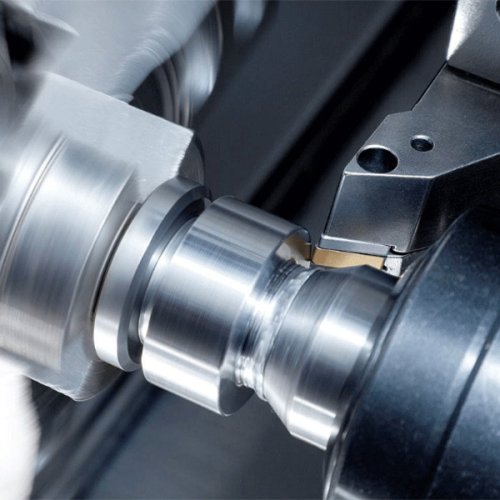

Custom CNC machining parts range from precision gears, shafts, and flanges to intricate brackets, enclosures, and aerospace components. Each part can be manufactured from metals or engineering plastics to meet unique dimensions, material properties, and performance standards. This flexibility makes CNC machining ideal for industries such as automotive, aerospace, electronics, medical devices, and industrial machinery, ensuring reliable performance and long service life.

EN

EN RU

RU