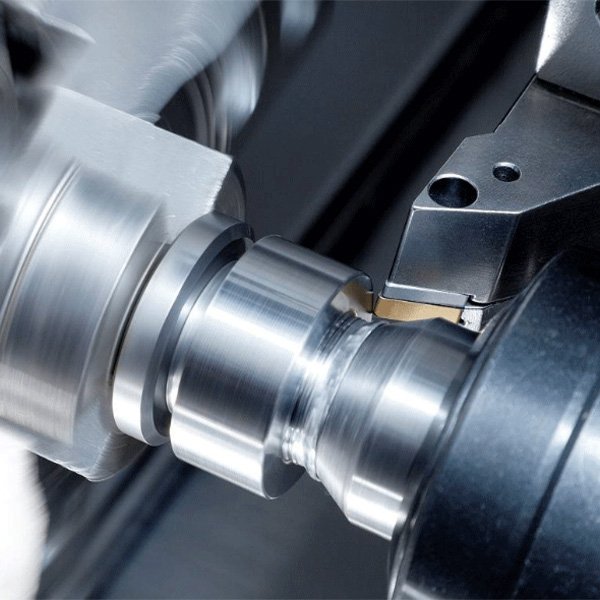

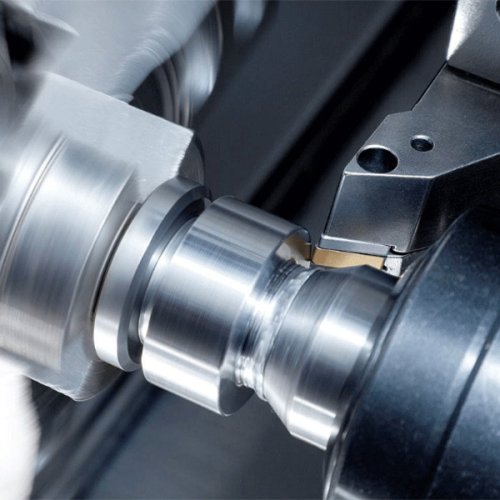

CNC Machining services is the process of providing OEM and ODM services according to customer drawings after receiving them. Companies with more complete supply chains and stronger teams can provide better services. Larger companies or factories may focus more on serving larger companies. Therefore, choosing a suitable partner is crucial for the company's future development. HULK Metal has a complete supply chain and a professional team. It can choose a more suitable factory according to the order details to develop a suitable solution and deliver orders that meet quality requirements.

EN

EN RU

RU