1. Higher Standard Certification

2. Shorter Production Cycle

3. More Types of Surface Treatment

4. More Cost-saving Freight Routes

5. More Comprehensive After Service.

| Name | Gear Forgings |

| Manufacturing | Manufacturing According to Drawings |

| Process | Precision Casting / Hot Forging / Die Forging |

| CNC Machining | Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring |

| Materials | High Manganese Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized |

| Surface | Spraying / Hot Galvanizing / Electro Galvanizing / BAlack / Anodizing / Customized |

| Certification | CE / GB / DIN / BSW /Customized |

| Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

| Serivce | Freight consulting / Quality inspection / After-sales / Other value-added services. |

| Delivery Method | Sea / Air / Land |

| Quality Assurance | Life-Long |

You will get the OEM gear forgings with the certification of CE, TUV, and ISO9001. HULK Metal has an experienced technical team and will track the production of the order throughout. We strictly inspect the raw materials, semi-finished products, and finished products of the order. The pass rate of each batch of orders can reach 98% and above.

You will get the OEM gear forgings with a shorter production cycle. HULK Metal is proficient in the production process of OEM gear forgings. A better solution can be designed according to the drawings you provide. Our production team can fulfill your order faster while maintaining the overall quality of the order.

You will get OEM gear forgings with more types of surface treatment. HULK Metal is proficient in polishing, wire drawing, sandblasting and other surface treatment processes, we will send free samples for your testing. The professional quality inspection team will also track the production of the order throughout the process, and inspect the surface of the product in an all-round way according to your requirements.

You will get OEM gear forgings with more cost-saving freight routes. HULK Metal has established a dedicated freight consultancy. After more than 10 years of development, it has reached close cooperation with hundreds of well-known freight companies around the world. It can plan more cost-effective freight routes based on your city.

You will enjoy more comprehensive after-service at HULK Metal. HULK Metal has established a professional after-sales service team to provide you with free technical consultation, order production status feedback, cargo transportation status feedback, quality information feedback, and other services. You can experience easier sourcing at HULK Metal.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

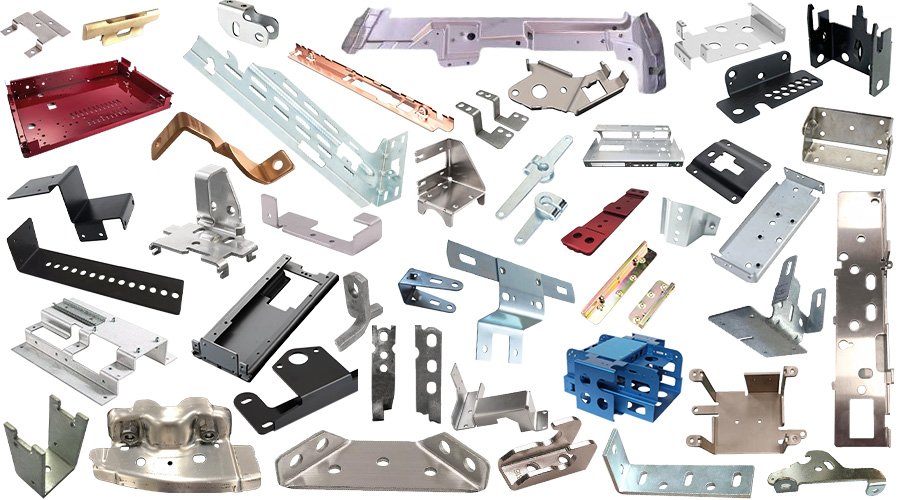

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Precision forging is a near-net-shape manufacturing process that creates high-strength components with superior mechanical properties. At HULK Metal, our OEM services integrate advanced hot and cold die forging with precision CNC machining.

HULK Metal provides a comprehensive OEM solution for high-precision forged steel parts, integrating advanced hot and cold forging factories with elite 5-axis CNC machining.

Description HULK Metal provides a vertically integrated manufacturing solution for Motorcycle Forged Parts, specializing in high-strength components like crankshafts, connecting rods, and triple clamps.

Mining environments demand components with exceptional wear resistance. HULK Metal manufactures custom mining forged parts using premium carbon and alloy steels.

ISO 9001-certified metal forging factory. The technical team supports every phase—from print review to process optimization. Faster turnaround without sacrificing accuracy. Full QA with returns/rework guarantee.

Forged gear blanks provide higher strength, better grain flow, and improved fatigue resistance compared with cut gears.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-precision CNC machining services for parts made from steel, stainless steel, aluminum, and alloys.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

HULK Metal provides premium push sleds designed for professional training and commercial gyms, offering diverse types, robust construction, and customizable features.

This product detail focuses on Monolift Rack Attachments. It covers features, manufacturing processes, quality control, and benefits.

HULK Metal provides premium OEM squat racks, including power racks, half racks, wall-mounted, foldable, and combo designs. Each rack is produced with precision metalworking, strict quality inspections, and advanced surface treatments.

HULK Metal''s Safety Spotter Arms are engineered for strength, safety, and long-term durability in commercial and home gym racks. Manufactured with high-quality steel, precise welding, and advanced surface treatments, each unit undergoes strict inspection and testing.

HULK Metal provides a comprehensive OEM manufacturing solution for rear base stabilizers, focusing on structural integrity and precision. Utilizing advanced robotic welding, CNC laser cutting, and professional surface treatments, we ensure every component achieves a 99.8% precision rate.

HULK Metal provides a comprehensive OEM manufacturing solution for high-strength fitness crossmembers, serving as the structural backbone for commercial power racks and functional rigs. By integrating ISO 9001-certified processes with advanced CNC laser cutting and robotic welding, we deliver rack crossmember components with a 99.8% precision rate.

HULK Metal provides durable, safe, and customizable medicine ball holder racks, including vertical, horizontal, and modular designs. With integrated factory resources, strict quality control, certified production, and comprehensive OEM services, we ensure faster delivery, competitive pricing, and reliable after-sales support. Ideal for commercial gyms, training centers, and bulk buyers seeking high-quality, long-lasting fitness storage solutions.

HULK Metal provides a comprehensive OEM solution for high-quality front foot extensions, utilizing advanced robotic welding, laser cutting, and ISO 9001-certified quality control. We deliver precision-engineered stabilizers that enhance equipment safety and footprint integrity for global fitness brands. Our vertically integrated factory ensures competitive pricing, rapid production cycles, and a 99.8% precision rate. Backed by a lifetime quality guarantee, we empower procurement teams to streamline their supply chain with durable, high-performance metal components.

HULK Metal provides a comprehensive OEM manufacturing solution for high-capacity dumbbell stands, prioritizing structural integrity and long-term durability. Our facility integrates ISO 9001 standards with advanced robotic welding and CNC laser cutting to achieve a 99.8% precision rate. From heavy-duty tiered racks to space-saving vertical towers, we manage the entire lifecycle—from raw material inspection to global logistics—delivering cost-effective, commercial-grade storage solutions that meet the rigorous safety and aesthetic demands of professional fitness environments.

HULK Metal provides a comprehensive OEM solution for the dip bar attachment, integrating high-wattage laser cutting and robotic welding to achieve a 99.8% precision rate. Our facility specializes in heavy-duty structural steel fabrication, offering diverse surface treatments like electrostatic powder coating for maximum durability. By optimizing our vertically integrated supply chain, we deliver certified, commercial-grade dip attachment units at competitive prices with accelerated lead times, ensuring a stable and high-quality inventory for global fitness brands.

HULK Metal provides high-capacity OEM manufacturing for commercial-grade Chin Up Bars, utilizing over 50 automated welding stations and high-speed fiber laser cutting. Our ISO 9001-certified factory ensures every component meets a 99.8% precision rate, delivering structural safety and aesthetic consistency.

Our heavy-duty Barbell Holder Attachment is engineered for seamless integration into commercial power racks and home gym systems. Utilizing high-grade steel and precision laser cutting, we provide comprehensive OEM services that transform your technical drawings into market-ready components.

HULK Metal delivers industrial-grade Weight Plate Tree manufacturing, transforming complex technical drawings into durable gym hardware. Our Bar and Weight Plate Tree OEM services prioritize structural integrity through advanced metalworking.

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU