Our technicians conduct thorough visual and tactile examinations to identify any coating irregularities, scratches, or burrs. We also perform salt spray testing and adhesion checks to guarantee the finish can withstand corrosive gym environments.

HULK Metal provides a comprehensive OEM manufacturing solution for rear base stabilizers, focusing on structural integrity and precision. Utilizing advanced robotic welding, CNC laser cutting, and professional surface treatments, we ensure every component achieves a 99.8% precision rate. Our vertically integrated supply chain and rigorous quality inspection protocols allow global fitness brands to secure high-durability hardware at competitive prices. From technical design support to global logistics, we deliver reliable foundations that enhance equipment safety and longevity.

1.ISO 9001 Certified Rear Base Stabilizer

Factory Our production lines integrate rigorous quality management protocols, ensuring every batch meets international safety standards and precise mechanical specifications consistently.

2.Professional Technical Team To Provide Support

Experienced engineers oversee every stage of production, from initial material selection to complex welding, ensuring your technical blueprints are executed perfectly.

3.Finalize Your Order Faster

By utilizing over 50 automated welding stations and high-speed CNC laser cutting, we significantly compress lead times for high-volume orders.

4.Perfect Quality Assurance Service

We guarantee total compliance with your specifications; our policy includes comprehensive returns or exchanges for any quality issues or shortages.

5.Finalize Rear Base Stabilizer At a Lower Price

Our optimized supply chain and large-scale manufacturing efficiency allow us to provide premium OEM components at highly competitive wholesale rates.

The Rear Base Stabilizer is critical for ensuring the structural integrity and user safety of heavy-duty fitness machinery. HULK Metal provides specialized OEM services, utilizing precision forging and robotic welding to manufacture components that withstand high-stress loads. Our technical expertise allows us to scale production while maintaining a 99.8% precision rate, helping partners secure reliable, cost-effective hardware solutions.

HULK Metal delivers comprehensive manufacturing solutions tailored to your technical specifications. We process premium steel, aluminum, and alloys through precision stamping, robotic welding, and advanced CNC machining to ensure structural stability. Our capabilities include diverse surface treatments like powder coating and anodizing for superior durability. Every batch undergoes rigorous testing for chemical composition and mechanical properties, backed by lifelong quality assurance and flexible, global logistics to streamline your procurement.

Name | Rear Base Stabilizer |

Manufacturing Methods | Manufacturing According to Drawings |

Raw Materials | Steel, SS (Stainless Steel),Alloy Steel, Aluminum |

Materials Types | Pipes, plates, strips, profiles |

Process | Stamping, Bending, Laser Cutting, Welding. CNC Machining: Turning, milling, polishing, grinding, drilling, and reaming, and so on Packaging, Delivery, After Service. |

Surface Treatment | Galvanized, Passivation, Powder Coating, Shot Blasting, Polishing, Anodizing, etc. |

Test Content & Data | 1.Chemical Composition; 2. Mechanical Properties; 3. Inspection of appearance, size, shape, and position tolerance; 4. Surface Quality; |

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

Delivery Method | Sea / Air / Land |

Quality Assurance | Life Long |

The Rear Base Stabilizer is the structural foundation of high-performance fitness equipment, engineered to ensure user safety and machine longevity. By integrating advanced robotic welding, precision CNC machining, and rigorous ISO 9001-certified quality controls, HULK Metal delivers OEM components that exceed global industry standards. From premium raw material sourcing to specialized surface treatments and a comprehensive after-sales guarantee, we provide the technical expertise and manufacturing scale required to optimize your global supply chain.

The Rear Base Stabilizer—frequently referred to in the industry as a base frame support, rear footer, or equipment stabilizer bar—is a foundational structural component engineered to anchor heavy-duty fitness apparatus. In the complex architecture of treadmills, elliptical trainers, and power racks, this component serves as the primary contact point between the machine's vertical load and the floor. Its central role in the system is to counteract the kinetic energy and vibrations generated during high-intensity operation. By broadening the footprint of the equipment, it prevents tipping, shifting, and lateral swaying, which are critical risks during vigorous workouts.

Technically, the stabilizer functions as a torque-resistant anchor. It is typically manufactured from heavy-gauge steel tubing or reinforced plate profiles to ensure it can withstand both static weight and dynamic impact. Beyond mere stability, the rear base often houses leveling feet or transport wheels, integrating mobility with structural rigidity. Without a high-precision stabilizer, the longevity of the entire machine is compromised; uneven stress distribution leads to frame fatigue and premature bearing failure. HULK Metal focuses on the OEM production of these components, utilizing robotic welding and precision bending to ensure that every unit provides a perfectly flat, level foundation that meets the exacting safety tolerances required by global fitness brands.

The most significant risk when sourcing stabilizers is material fatigue under dynamic loads. If the wall thickness of the steel pipe is inconsistent or the alloy grade is substandard, the base may buckle or deform over time. To solve this, buyers must demand mill test certificates for all raw materials. At HULK Metal, we utilize ultrasonic thickness gauges and mechanical property testing to verify that every batch of steel exceeds the required tensile strength, ensuring the base remains rigid under peak operational stress.

Inadequate weld penetration at the junction of the stabilizer and the main frame is a common point of catastrophic failure. Poorly executed manual welds often hide porosities that crack under vibration. The solution lies in automated production. We utilize over 50 automated welding stations that deliver deep-penetration, consistent beads. This robotic precision eliminates human error and ensures that the weldment can withstand millions of vibration cycles without compromising the structural safety of the fitness equipment.

Rear bases are frequently exposed to cleaning chemicals and perspiration, which can lead to rapid oxidation if the surface treatment is thin or porous. A low-quality powder coating will flake, leading to rust. Buyers should specify salt spray testing durations. Our solution involves a multi-stage pretreatment process, including shot blasting and chemical passivation, followed by high-grade powder coating. This creates an impermeable barrier that maintains aesthetic appeal and structural health even in high-humidity gym environments.

A common headache for fitness equipment assembly lines is a stabilizer with warped mounting holes or skewed angles, making it impossible to bolt to the main frame. This is usually caused by thermal deformation during welding. We address this by using high-precision welding jigs and post-weld CNC machining. By milling the mounting surfaces and drilling holes after the welding process is complete, we achieve a 99.8% precision rate, ensuring a "perfect fit" for the end-user.

Purchasing a stabilizer that lacks precise threading for leveling feet leads to "rocking" equipment, which ruins the user experience. Many suppliers use low-quality taps that strip easily. Our technical solution involves using CNC-controlled tapping and threading to ensure internal threads are perfectly perpendicular and robust. This allows for smooth adjustment of leveling feet, ensuring the equipment remains completely stationary on uneven surfaces, thereby protecting both the machine and the flooring.

Intense heat during the welding of heavy-gauge steel causes the stabilizer bar to warp or "bow," resulting in a base that does not sit flush against the floor.

We employ custom-engineered water-cooled welding fixtures and a specific "staggered" welding sequence. This controlled thermal management, combined with automated robotic arms, minimizes heat concentration. If any deviation remains, our technicians utilize hydraulic straightening presses to restore the component to its exact geometric blueprint before final inspection.

Standard punching methods often result in slight shifts in hole positioning, leading to significant assembly delays when the stabilizer is mated to the treadmill or rack frame.

We have transitioned from traditional punching to high-speed CNC laser cutting and post-weld CNC drilling. By machining the holes after the structural welding is complete, we eliminate the impact of material shrinkage. This process ensures that every mounting point aligns perfectly with your assembly jigs, every single time.

For stabilizers involving cast iron or aluminum ends, internal gas pockets (porosity) can weaken the structure and cause the surface finish to bubble during the curing process.

Our casting process utilizes vacuum-assisted pouring and X-ray flaw detection to identify internal voids. For the surface, we implement a rigorous degasifying pre-heat cycle before powder coating. This drives out any trapped air, ensuring a smooth, crater-free finish that meets the highest aesthetic standards.

During the pickling and galvanizing process, high-strength steel can absorb hydrogen, making the stabilizer brittle and prone to sudden cracking under heavy weight or impact.

We implement a strict post-plating baking process for all high-tensile components. By heating the parts to a specific temperature for a set duration immediately after coating, we effectively remove absorbed hydrogen. This preserves the ductility of the metal, ensuring the stabilizer remains tough and reliable.

Powder coating tends to pull away from sharp corners during curing, leaving "thin spots" where rust begins to form almost immediately in a gym environment.

All of our stabilizers undergo an automated edge-rounding process (deburring) before they reach the coating line. By creating a consistent radius on all cut edges, we ensure the powder coating adheres uniformly around the entire profile. This provides 360-degree protection and a premium, professional feel.

The manufacturing of a Rear Base Stabilizer at HULK Metal is a rigorous, multi-stage process that transforms raw metal into a high-precision structural component. We integrate advanced automation with strict quality gates at every transition, ensuring that the final product aligns perfectly with your OEM technical specifications and durability requirements.

Our engineering leads conduct a comprehensive review of your technical drawings to select the most efficient production path. We evaluate material thickness, load-bearing requirements, and tolerance levels to decide between laser cutting, stamping, or specialized forging. This initial strategic planning ensures structural integrity while optimizing manufacturing costs for high-volume orders.

For customized profiles or complex bracket shapes, our in-house toolroom designs and fabricates precision molds. We perform multiple trial runs to debug the tooling, ensuring that the dimensions remain consistent across thousands of cycles. This rigorous testing phase eliminates the risk of geometric drift during full-scale production runs.

We source premium steel and aluminum alloys only from certified Tier-1 mills. Each batch of raw material undergoes spectral analysis to verify chemical composition and tensile testing to confirm mechanical strength. By strictly controlling the input quality, we prevent issues like stress cracking or premature oxidation in the finished stabilizer.

The core of our manufacturing involves a synchronized workflow of high-tech metalworking. We utilize high-power CNC laser cutting to achieve complex geometries with a 99.8% precision rate, followed by heavy-duty hydraulic bending and stamping to form the primary structure. The most critical phase is the structural integration, where we employ over 50 automated welding stations. These robotic systems deliver consistent, deep-penetration beads that manual welding cannot replicate, significantly enhancing the fatigue resistance of the base. Following fabrication, the components move to our automated surface treatment line. Here, they undergo shot blasting to remove impurities, followed by professional-grade powder coating or galvanization to provide a corrosion-resistant barrier. Finally, any integrated parts, such as leveling feet or transport wheels, are assembled using calibrated torque tools. This industrial-scale approach allows us to maintain high throughput without compromising the micro-tolerances required for high-end fitness equipment.

Post-production, every Rear Base Stabilizer undergoes a multi-point inspection protocol. We use CMM (Coordinate Measuring Machine) technology to verify dimensional accuracy and perform non-destructive testing on weld joints to ensure zero internal defects. Only components that pass 100% of these checks are cleared for the final packaging stage.

Components are packed according to your specific requirements, whether in custom wooden cases, reinforced cartons, or bulk crates. We utilize protective wrapping to prevent surface scratches during transit. Our logistics team coordinates sea, air, or land freight, providing all necessary documentation to ensure a seamless customs process and timely delivery.

HULK Metal provides lifelong quality assurance for every stabilizer we produce. Our commitment extends far beyond delivery; we offer comprehensive support for any quality-related inquiries or quantity discrepancies. If a defect is identified, we facilitate rapid returns, exchanges, or restocking to ensure your assembly line continues to operate without interruption.

To ensure your Rear Base Stabilizer withstands corrosive gym environments and heavy physical impact, HULK Metal provides a comprehensive suite of finishing services. We utilize advanced chemical, mechanical, and electrostatic processes to enhance both the durability and aesthetics of every component.

Category | Surface Treatment Methods | Technical Description and Value |

Electrochemical & Chemical | Galvanized, Passivation, Anodizing, Zinc Plating, Electrophoresis (E-coating). | These processes involve submerging the metal in chemical baths or electrolytic solutions to create a protective molecular layer. Galvanization and Zinc Plating provide sacrificial cathodic protection against rust, while Anodizing is essential for aluminum stabilizers to increase surface hardness and wear resistance. Passivation removes free iron from the surface of stainless steel to maximize its natural corrosion resistance. E-coating ensures 100% coverage even in deep internal cavities of tubing, providing a consistent primer base that prevents oxidation from the inside out, which is vital for the long-term structural integrity of fitness frames. |

Electrostatic Adsorption | Powder Coating, Spray Painting, Electrostatic Spraying. | Powder Coating is our primary recommendation for fitness equipment bases due to its superior impact resistance and thickness. We use electrostatic guns to apply charged plastic resin powder, which is then cured under high heat to form a hard, "skin-like" finish. This process is far more durable than traditional liquid paint, resisting the chipping and scratching caused by gym shoes and equipment weights. It allows for a vast range of textures (matte, gloss, or sand-grain) and colors, ensuring the stabilizer perfectly matches your brand’s aesthetic while providing an impermeable barrier against perspiration. |

Mechanical & Physical | Shot Blasting, Polishing, Grinding, Brushing, Sand Blasting. | These methods physically alter the metal's surface texture to prepare it for coating or to provide a final decorative finish. Shot Blasting is a critical pretreatment step at HULK Metal; it uses high-velocity steel grit to strip away mill scale and impurities, creating a "mechanical anchor" for better coating adhesion. For high-end stainless steel components, we utilize multi-stage Polishing and Brushing to achieve a mirror or satin finish. These physical treatments ensure the surface is smooth to the touch, eliminating any sharp burrs or irregularities that could compromise user safety or finish quality. |

Selecting the right manufacturing partner is the most critical decision in your supply chain. In the competitive Chinese market, a reliable factory must go beyond basic production. You need a partner that integrates technical expertise, massive capacity, and a transparent service model to ensure your Rear Base Stabilizers meet international fitness safety standards.

A factory is only as good as the engineers behind the machinery. A professional technical team ensures that your complex blueprints are translated into high-performance components. They identify potential structural weaknesses before production begins and optimize the manufacturing process for durability. At HULK Metal, our senior engineers provide a 99.8% precision rate in CNC machining and welding, ensuring every stabilizer handles dynamic loads safely.

Consistency in high-volume orders requires significant industrial infrastructure. Choosing a factory with strong production capacity ensures your project won't be delayed during peak seasons. With over 50 automated welding stations and advanced laser cutting machinery, we can scale production rapidly to meet the demands of global gym equipment brands without sacrificing the micro-tolerances required for high-end fitness frames.

The factory must implement a rigorous quality management system, ideally ISO 9001 certified, to guarantee batch-to-batch consistency. This involves multi-stage inspections, from raw material chemical analysis to final stress testing of the welds. We strictly enforce these standards for every order, ensuring that no substandard components ever leave our factory floor, protecting your brand reputation and user safety.

A reliable factory integrates a complete supply chain, from sourcing Tier-1 raw materials to advanced surface treatment facilities. This vertical integration reduces lead times and minimizes the risks associated with outsourcing. By controlling the entire process—including forging, casting, and powder coating—HULK Metal provides a more stable price point and higher quality control than factories that rely on multiple external vendors.

Effective communication and professional project management are essential for successful OEM partnerships. A comprehensive service system means having dedicated account managers who provide technical consultation, progress updates, and rapid problem-solving. We offer a "one-stop" experience that covers everything from technical feasibility studies to after-sales support, ensuring a seamless procurement process for our international bulk buyers.

Financial flexibility is a hallmark of a mature, global supplier. You should look for a factory that supports diverse payment methods like T/T, L/C, or PayPal and offers flexible Incoterms such as FOB, CIF, or DDP. This adaptability helps you manage your cash flow and logistics risks more effectively. HULK Metal works with you to establish mutually beneficial terms that reflect long-term cooperation.

Navigating international logistics can be complex, so your partner must have extensive experience in global shipping. Whether you require sea, air, or land freight, a factory with a professional logistics team ensures that your Rear Base Stabilizers are packaged securely and delivered on time. We coordinate all customs documentation and freight consulting to ensure a hassle-free arrival at your destination port.

True partners stand behind their work with a clear quality assurance policy. You should prioritize factories that offer comprehensive after-sales services, including returns and exchanges for quality issues or quantity shortages. We provide lifelong quality assurance for our metal components; if any part fails to meet your specifications, we take full responsibility to rectify the issue, ensuring your production line never stops.

A: We maintain a fully equipped quality inspection center and implement rigorous testing procedures throughout the production cycle. By utilizing a complete quality assurance system, including spectral analysis for raw materials and CMM for dimensional accuracy, we ensure every batch adheres strictly to your engineering tolerances and safety standards.

A: Pricing is determined by several technical variables, including raw material grades, tolerance requirements, overall size, and surface treatment complexity. Because we own our factory, we can provide real-time, transparent quotes that reflect current market costs while ensuring you receive the most competitive wholesale rates available.

A: Our pricing strategy is built on a foundation of premium quality. While we never compromise on structural integrity, our optimized manufacturing processes allow us to offer lower prices than competitors for the same quality level. Additionally, placing larger volume orders enables us to pass on significant economies of scale.

A: The Minimum Order Quantity is influenced by factors such as material type, component size, and manufacturing complexity. We encourage you to send us your technical drawings; we will sign a non-disclosure agreement (NDA) to protect your intellectual property before evaluating the project and providing a specific MOQ.

A: Our delivery timeline is highly responsive to your procurement schedule. Generally, the production cycle is around 30 days, as our automated welding and cutting stations increase efficiency for repeat orders. Even for complex, high-volume batches, we ensure that the total lead time usually will not exceed 45 days.

A: We provide a diverse range of finishes through close partnerships with specialized powder coating and galvanizing centers. We evaluate the base material and intended application environment to recommend the most suitable solution, ensuring your Rear Base Stabilizers offer both exceptional aesthetic appeal and long-term resistance to corrosion.

A: We operate a global logistics network and have successfully delivered high-quality fitness components to clients in more than 50 countries. Our experience spans major markets across Europe, North America, South America, Africa, and Southeast Asia, ensuring we can handle the specific customs and shipping requirements of your region.

A: Our manufacturing capabilities are highly versatile, accommodating various thicknesses, shapes, and material grades. To determine the feasibility for your specific model, please provide your 2D or 3D drawings under a signed NDA. Our technical team will evaluate the geometry and production process to confirm our manufacturing compatibility.

A: To facilitate smooth international trade, we support a variety of flexible payment terms, including L/C and T/T. We are committed to establishing mutually beneficial partnerships and will comprehensively consider any specific financial or delivery requirements you may have to ensure a seamless and professional transaction process.

A: HULK Metal is a comprehensive manufacturer with extensive factory resources and specialized production lines. Our team provides full-spectrum support, integrating technical engineering, strategic procurement, and professional foreign trade sales to ensure you receive a higher level of service and technical reliability than a standard trading company.

A: Absolutely. We prioritize precision, so we will produce and rigorously test a prototype sample according to your specifications. This sample is sent to you for final verification; mass production only commences once the sample has passed your internal testing and received your formal approval.

A: You can get a quote in a shorter time by providing the following information at once:

1. 2D and 3D drawings of the Rear Base Stabilizer. If neither is available, samples can be provided.

2. Quantity.

3. Delivery Terms.

4. Material, surface treatment, tolerance, and weight. If no 3D drawing is available, please provide the following information:

Our ability to deliver superior components stems from a relentless focus on technical precision and industrial discipline. We do not simply manufacture parts; we engineer structural solutions that enhance the lifespan and safety of your fitness equipment.

Our professional technical team possesses decades of experience in metal fabrication, allowing them to interpret complex blueprints with absolute accuracy. We engage in deep technical consultations to understand the specific stress loads and environmental factors your equipment will face, developing optimized manufacturing solutions that align perfectly with your brand's quality benchmarks.

We have spent years cultivating a robust and integrated supply chain that covers every aspect of production, from smelting to specialized surface finishing. This network allows us to maintain total control over lead times and component consistency, ensuring that every Rear Base Stabilizer is produced using the most efficient and reliable industrial resources available in China.

Quality begins with the substrate. Our close cooperation with Tier-1 raw material mills allows us to source high-grade steel and aluminum at preferential rates without compromising on chemical purity or mechanical strength. Every batch of incoming material undergoes spectral analysis and tensile testing to ensure it meets the rigid requirements of heavy-duty fitness applications.

We utilize a high-precision manufacturing environment featuring over 50 automated welding stations and advanced CNC laser cutting systems. By minimizing human intervention in critical structural processes, we achieve a 99.8% precision rate. This strict adherence to automated protocols ensures that every stabilizer is identical, with uniform weld penetration and perfect geometric alignment across thousands of units.

Our quality control goes far beyond a simple visual check. Each Rear Base Stabilizer must pass a series of rigorous evaluations, including ultrasonic weld testing, CMM dimensional verification, and salt spray testing for surface durability. This data-driven approach ensures that only components that meet 100% of your specified tolerances are cleared for shipment.

High-quality products deserve high-quality protection. We design customized packaging solutions, ranging from reinforced wooden crates to individually wrapped units, to ensure that your stabilizers arrive in pristine condition. Our logistics team manages the entire shipping process, selecting the most reliable freight routes to prevent transit damage and ensure timely arrival at your facility.

Our partnership does not end at the loading dock. We provide a transparent and accountable after-sales system where you can verify the quality and quantity of goods upon arrival. To safeguard your interests, any products with verified quality discrepancies or shortages are eligible for our comprehensive return, exchange, and restocking services, ensuring your assembly line never experiences downtime.

HULK Metal implements a multi-layered quality inspection framework to ensure that every Rear Base Stabilizer aligns perfectly with your engineering blueprints. Our protocol integrates advanced metrology, material science, and rigorous visual standards to eliminate defects before they reach your assembly line. By maintaining a 99.8% precision rate through systematic testing, we provide the technical reliability necessary for high-intensity commercial fitness equipment and long-term brand trust.

Our technicians conduct thorough visual and tactile examinations to identify any coating irregularities, scratches, or burrs. We also perform salt spray testing and adhesion checks to guarantee the finish can withstand corrosive gym environments.

We utilize Coordinate Measuring Machines (CMM) and high-precision digital calipers to verify that every geometric parameter, from hole alignment to overall length, meets your specified tolerances. This ensures a seamless fit during final product assembly.

Every batch of raw material undergoes spectral analysis to confirm chemical composition and hardness testing to verify alloy grades. We only utilize materials from certified mills that meet international strength and durability standards.

To ensure structural safety, we subject the stabilizers to load-bearing and fatigue tests. This verifies that the weldments and metal profiles can handle dynamic stress without deformation or failure during vigorous user exercise sessions.

We implement strict counting protocols during the packaging phase to prevent discrepancies. Every crate is cross-referenced with the packing list and purchase order to ensure that the exact number of units is delivered as requested.

Before sealing any container, our QC team performs a final comprehensive audit of the batch. This includes a review of all previous test reports and a random sampling of finished units to ensure consistent quality across the entire order.

HULK Metal provides all necessary documentation, including mill test certificates and compliance reports, to facilitate a smooth customs clearance process. We ensure all components are labeled and packed according to international shipping regulations to avoid delays.

HULK Metal operates a sophisticated manufacturing ecosystem designed specifically for high-precision fitness equipment hardware. Our factory integrates specialized workshops for metal fabrication, robotic welding, and advanced laser cutting, all supported by an in-house surface treatment center. By consolidating these capabilities under a single ISO 9001-certified management system, we ensure seamless production transitions, reduced lead times, and rigorous quality oversight that meets the demanding standards of global OEM partners.

Our primary fabrication center is equipped with heavy-duty hydraulic presses and CNC bending machinery capable of processing high-tensile steel and aluminum profiles. We focus on the structural integrity of the rear base stabilizer, ensuring that every bend and stamp maintains uniform wall thickness. The factory is organized for high-volume throughput, allowing us to transition from raw material to semi-finished frames with extreme efficiency while maintaining the microtolerances required for precision fitness machinery.

The welding workshop is the heart of our structural production, featuring over 50 automated robotic welding stations. These systems are programmed to deliver consistent, deep-penetration beads that maximize the fatigue resistance of every stabilizer joint. By utilizing robotic automation, we eliminate the variability of manual labor, ensuring that every component can withstand the intense dynamic loads of commercial gym environments. Our certified welding technicians oversee the process to ensure 100% compliance with international safety specifications.

HULK Metal manages an integrated surface treatment factory specializing in durable finishes like powder coating, galvanization, and anodizing. We implement a rigorous multi-stage pretreatment process, including shot blasting and chemical degreasing, to ensure maximum coating adhesion. This controlled environment allows us to produce stabilizers with superior corrosion resistance and aesthetic consistency. By managing this process in-house, we guarantee that the finish will not chip or fade under the high-perspiration conditions typical of fitness environments.

Our laser cutting workshop utilizes high-power CNC fiber lasers to achieve complex geometries with a 99.8% precision rate. This technology allows us to cut mounting holes and intricate profiles directly from technical drawings without the need for secondary machining in many cases. The speed and accuracy of our laser systems significantly reduce material waste and ensure that every rear base stabilizer features perfectly aligned attachment points, facilitating rapid and error-free assembly for our global clients.

The Quality Control Center is an independent facility equipped with advanced metrology tools, including Coordinate Measuring Machines (CMMs) and spectral analyzers. Our dedicated QC team performs 100% inspections on critical dimensions and conducts destructive and non-destructive testing on weldments. This center serves as the final gatekeeper, ensuring that every batch of rear base stabilizers meets the chemical, mechanical, and aesthetic requirements specified in your OEM contract before being cleared for global shipment.

Choosing HULK Metal as your manufacturing partner provides a strategic advantage through technical excellence and supply chain efficiency. We deliver a comprehensive OEM service that combines high-precision robotic welding with rigorous ISO-certified quality management. By leveraging our massive production capacity and integrated logistics, global fitness brands can secure durable, safety-compliant stabilizers at a lower total cost, ensuring their equipment maintains a competitive edge in the demanding commercial gym market.

Choosing HULK Metal as your manufacturing partner provides a strategic advantage through technical excellence and supply chain efficiency. We deliver a comprehensive OEM service that combines high-precision robotic welding with rigorous ISO-certified quality management. By leveraging our massive production capacity and integrated logistics, global fitness brands can secure durable, safety-compliant stabilizers at a lower total cost, ensuring their equipment maintains a competitive edge in the demanding commercial gym market.

Our large-scale manufacturing infrastructure and long-term partnerships with raw material mills allow us to provide premium components at highly competitive wholesale rates. By utilizing automated production, we reduce labor costs and material waste, passing these savings directly to our clients. When compared to other suppliers maintaining the same quality standards, HULK Metal’s optimized supply chain ensures a lower unit price, allowing you to improve your profit margins while maintaining the structural excellence of your fitness apparatus.

Stabilizer We offer a vertically integrated manufacturing process that transforms your technical drawings into market-ready components. Our expertise encompasses the entire production lifecycle, including precision stamping, CNC bending, and advanced robotic welding. By managing every stage in-house—from material procurement to final surface treatment—we eliminate the complexities of multi-vendor sourcing. This "one-stop" approach ensures that every rear base stabilizer is structurally optimized for your specific fitness machinery, providing a perfect fit and consistent performance across every production batch.

In the fast-paced fitness industry, speed to market is a critical competitive factor. HULK Metal utilizes over 50 automated welding stations and high-speed fiber laser cutting technology to significantly compress production lead times. Our streamlined workflow and optimized logistics coordination ensure that high-volume orders are finalized and shipped within 30 to 45 days. By reducing manufacturing bottlenecks, we help you maintain lean inventory levels and respond rapidly to fluctuations in consumer demand without compromising on quality.

Safety standards are non-negotiable in fitness equipment manufacturing. Our factory operates under a strict ISO 9001 quality management system, and our products can be manufactured to meet CE, UL, and other international safety certifications. We utilize spectral analysis to verify material composition and conduct destructive load testing to ensure structural integrity. This commitment to global standards provides our clients with the necessary documentation and peace of mind to export their equipment into highly regulated markets without the risk of safety failures.

Overview Beyond stabilizers, HULK Metal manufactures a diverse range of high-precision fitness hardware designed to integrate seamlessly into your machinery. Our production capabilities extend to heavy-duty weight stack guide rods, ergonomic adjustment handles, main frame uprights, and reinforced pulley brackets. We utilize the same rigorous CNC machining and ISO-certified quality standards across all components, ensuring that every element—from the smallest pivot pin to the largest structural base—meets the exacting durability requirements of the global fitness industry.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

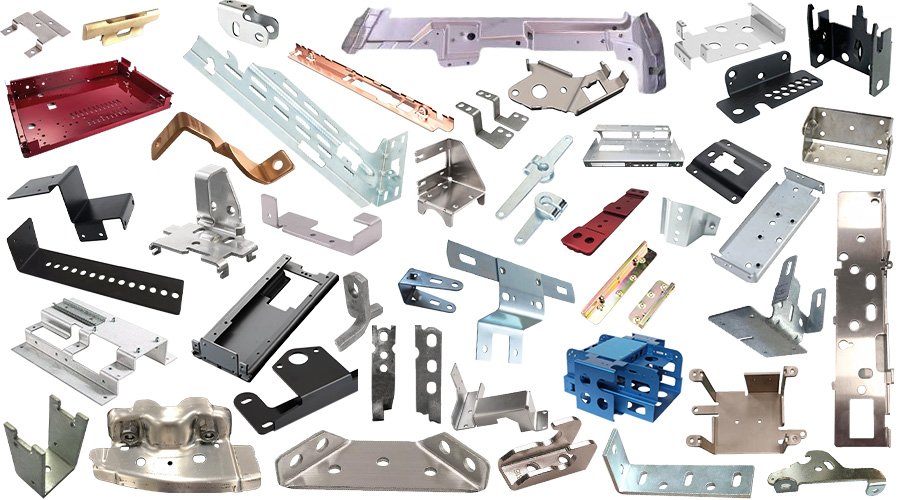

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

HULK Metal delivers high-precision gym equipment parts engineered for commercial durability and performance. Leveraging advanced manufacturing processes—including casting, forging, stamping, and welding—we produce components that meet tighter tolerances, higher load capacities, and longer service life compared to conventional alternatives. Every part is crafted from premium materials like steel, stainless steel, or aluminum, and undergoes rigorous quality checks. Our customization capabilities allow seamless integration into any commercial custom gym equipment system, ensuring reliability, consistency, and scalability for global fitness brands seeking a trusted OEM partner.

Aluminum Die Casting Parts are widely used for structural and functional components requiring strength, accuracy, and clean surfaces.

Sand Casting Parts are widely used for producing durable metal components with complex shapes and stable performance. As an experienced Sand Casting Parts manufacturer, HULK Metal provides Custom Sand Casting Parts and OEM Sand Casting Parts based strictly on customer drawings.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

A Die Casting Junction Box made from aluminum offers reliable protection, precise structure, and stable performance for electrical systems.

HULK Metal offers premium Aluminum Die Casting Heatsinks through a fully integrated OEM process, including die casting, CNC machining, surface treatment, and quality inspection.

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Steel Casting Parts are widely used for load-bearing and structural components requiring strength, durability, and dimensional stability.

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Cast Aluminum Enclosures are widely used to protect electronic and industrial components in demanding environments.

We manufacture bike parts strictly according to customer drawings, covering drivetrain, braking, wheel, and structural components. Our OEM service integrates casting, CNC machining, surface treatment, packaging, and logistics under one managed process.

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

HULK Metal provides OEM Precision Die Casting Parts with full technical support, strict quality control, and reliable production.

HULK Metal delivers high-quality OEM casting aluminum brackets made to your exact drawings, using die casting, sand casting, or investment casting.

HULK Metal provides comprehensive Aluminium Die Casting Auto Parts solutions, covering engine, transmission, chassis, and electronic components. We meticulously manage every stage, from mold design, die casting, CNC machining, and surface treatment, to strict quality control, packaging, and delivery.

HULK Metal has provided excellent Agricultural Machinery Casting services to hundreds of customers worldwide.

HULK Metal supplies Automobile Casting Components for global automotive manufacturers and bulk buyers seeking reliable OEM partners in China. With ISO 9001 certified factories and mature casting experience, we produce Automobile Casting Parts strictly according to drawings.

HULK Metal specializes in OEM/ODM casting of Custom Flail Mower Hammer Blades. With an ISO 9001-certified factory, advanced foundry capabilities, and end-to-end quality control, we deliver wear-resistant, dimensionally accurate blades tailored to your machinery.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Die Casting Engine Parts are widely used in automotive and industrial power systems where strength, accuracy, and heat dissipation matter.

HULK Metal is a trusted manufacturer of Custom Sickle Guards Casting, serving bulk buyers worldwide. Our ISO 9001-certified foundry delivers high-precision sickle guards in ductile iron, grey iron, or cast steel—tailored to your drawings.

HULK Metal delivers precise and durable Water Glass Sand Casting components for industrial and OEM applications. Combining advanced factories, CNC machining, comprehensive surface treatments, and rigorous quality control, we ensure reliable production and timely delivery.

Our Stainless Steel Castings are produced for demanding industrial applications where strength, corrosion resistance, and consistency matter. As an OEM-focused supplier, we manufacture strictly according to your drawings using sand casting, investment casting, or lost foam casting.

Resin sand casting is widely used for medium and large metal parts requiring good surface finish and stable structure.

HULK Metal provides professional reducer housing casting services, offering horizontal, vertical, integral, and split designs. Our complete OEM solutions include casting, CNC machining, surface treatment, quality inspection, packaging, and global delivery.

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

HULK Metal operates as a trusted Casting Motorcycle Parts manufacturer in China, specializing in aluminum die casting and sand casting motorcycle parts. Backed by ISO 9001 standards, our factories deliver precision OEM components tailored to your drawings.

Lost wax casting is ideal for producing complex metal parts with smooth surfaces and tight tolerances. As an experienced lost wax casting foundry in China, HULK Metal provides reliable OEM services based on your drawings.

HULK Metal provides comprehensive lost foam casting solutions for OEM projects, covering mold design, casting, CNC machining, surface treatment, and quality inspection.

Investment casting produces complex metal parts with smooth surfaces and tight tolerances through a precise lost wax process.

HULK Metal delivers ISO 9001-certified grey iron casting services with precision, durability, and cost efficiency.

HULK Metal has provided excellent metal casting services to hundreds of ductile iron casting parts purchasers around the world. More than 20 industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction, agriculture, and energy, have used our products.

HULK Metal delivers high-quality custom cast iron drain pipe fittings through ISO 9001-certified factories. Our experienced team ensures precise production from drawings, rigorous quality control, and timely delivery.

You will get higher quality Centrifugal Casting Castings. HULK Metal has an advanced centrifugal casting production line that can produce cast iron, gray iron, ductile iron, stainless steel, high manganese steel and other raw materials.

HULK Metal has provided excellent metal casting services to hundreds of Cast Iron Casting parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

Precision forging is a near-net-shape manufacturing process that creates high-strength components with superior mechanical properties. At HULK Metal, our OEM services integrate advanced hot and cold die forging with precision CNC machining.

HULK Metal provides a comprehensive OEM solution for high-precision forged steel parts, integrating advanced hot and cold forging factories with elite 5-axis CNC machining.

Description HULK Metal provides a vertically integrated manufacturing solution for Motorcycle Forged Parts, specializing in high-strength components like crankshafts, connecting rods, and triple clamps.

Mining environments demand components with exceptional wear resistance. HULK Metal manufactures custom mining forged parts using premium carbon and alloy steels.

ISO 9001-certified metal forging factory. The technical team supports every phase—from print review to process optimization. Faster turnaround without sacrificing accuracy. Full QA with returns/rework guarantee.

Forged gear blanks provide higher strength, better grain flow, and improved fatigue resistance compared with cut gears.

Forging small parts are widely used where strength, consistency, and tight tolerances matter. HULK Metal provides OEM services for custom forging small parts based on drawings or samples.

HULK Metal provides premium forged flanges manufactured with hot die forging and precise CNC machining. Our services cover raw material selection, surface treatment, strict quality inspection, and timely delivery.

Custom forged parts from HULK Metal offer superior strength, reliability, and performance across industries like automotive, construction, and energy. Using advanced forging techniques and a comprehensive quality control system, we provide parts made to your exact specifications.

Closed die forged parts are produced by shaping heated metal within precision dies, delivering higher strength, consistent grain flow, and tight tolerances.

HULK Metal’s forged components include manufacturing processes, materials, surface treatments, and quality control measures. From automotive to industrial applications, our forged components deliver superior performance and reliability

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

HULK Metal specialises in high-quality forged stainless steel parts and offers comprehensive OEM services. As a certified ISO 9001 factory in China, we ensure strict quality control, competitive pricing, and rapid order turnaround.

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Custom hot forging parts are produced through controlled heating, precision die forging, machining, inspection, and delivery. HULK Metal supports OEM projects based on drawings, combining experienced technical teams, coordinated factories, and ISO 9001 management.

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Carbon Steel Forged Parts are widely used in applications where strength, durability, and dimensional stability are important. HULK Metal supplies Custom Carbon Steel Forged Parts through full OEM services, from drawing review, forging, machining, surface treatment to delivery.

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete custom stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales. You can buy metal stamping parts you want more easily at HULK Metal.

HULK Metal provides Custom Construction Metal Stamping Services for bulk buyers who demand precision, strength, and consistency.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

HULK Metal provides high-quality Aluminum CNC Machining Parts, combining advanced multi-axis CNC machining, precise surface treatments, and strict quality control.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

HULK Metal delivers high-precision CNC auto parts through ISO 9001-certified factories in China, offering full OEM machining services—from design review and material sourcing to surface treatment, rigorous inspection, and global delivery.

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Precision Machining for Agricultural Parts requires stable accuracy, durable materials, and consistent production control. HULK Metal provides Agricultural Sector Parts Machining Services based on customer drawings, covering turning, milling, drilling, and finishing.

Precision bicycle part machining demands tight tolerances, lightweight strength, and flawless surface finishes—exactly what HULK Metal delivers.

HULK Metal delivers precision custom flange machining based on your drawings, using advanced 3-, 4-, and 5-axis CNC equipment in ISO 9001-certified factories.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

HULK Metal''s Safety Spotter Arms are engineered for strength, safety, and long-term durability in commercial and home gym racks. Manufactured with high-quality steel, precise welding, and advanced surface treatments, each unit undergoes strict inspection and testing.

HULK Metal provides a comprehensive OEM manufacturing solution for rear base stabilizers, focusing on structural integrity and precision. Utilizing advanced robotic welding, CNC laser cutting, and professional surface treatments, we ensure every component achieves a 99.8% precision rate.

HULK Metal provides a comprehensive OEM manufacturing solution for high-strength fitness crossmembers, serving as the structural backbone for commercial power racks and functional rigs. By integrating ISO 9001-certified processes with advanced CNC laser cutting and robotic welding, we deliver rack crossmember components with a 99.8% precision rate.

HULK Metal provides durable, safe, and customizable medicine ball holder racks, including vertical, horizontal, and modular designs. With integrated factory resources, strict quality control, certified production, and comprehensive OEM services, we ensure faster delivery, competitive pricing, and reliable after-sales support. Ideal for commercial gyms, training centers, and bulk buyers seeking high-quality, long-lasting fitness storage solutions.

HULK Metal provides a comprehensive OEM solution for high-quality front foot extensions, utilizing advanced robotic welding, laser cutting, and ISO 9001-certified quality control. We deliver precision-engineered stabilizers that enhance equipment safety and footprint integrity for global fitness brands. Our vertically integrated factory ensures competitive pricing, rapid production cycles, and a 99.8% precision rate. Backed by a lifetime quality guarantee, we empower procurement teams to streamline their supply chain with durable, high-performance metal components.

HULK Metal provides a comprehensive OEM manufacturing solution for high-capacity dumbbell stands, prioritizing structural integrity and long-term durability. Our facility integrates ISO 9001 standards with advanced robotic welding and CNC laser cutting to achieve a 99.8% precision rate. From heavy-duty tiered racks to space-saving vertical towers, we manage the entire lifecycle—from raw material inspection to global logistics—delivering cost-effective, commercial-grade storage solutions that meet the rigorous safety and aesthetic demands of professional fitness environments.

HULK Metal provides a comprehensive OEM solution for the dip bar attachment, integrating high-wattage laser cutting and robotic welding to achieve a 99.8% precision rate. Our facility specializes in heavy-duty structural steel fabrication, offering diverse surface treatments like electrostatic powder coating for maximum durability. By optimizing our vertically integrated supply chain, we deliver certified, commercial-grade dip attachment units at competitive prices with accelerated lead times, ensuring a stable and high-quality inventory for global fitness brands.

HULK Metal provides high-capacity OEM manufacturing for commercial-grade Chin Up Bars, utilizing over 50 automated welding stations and high-speed fiber laser cutting. Our ISO 9001-certified factory ensures every component meets a 99.8% precision rate, delivering structural safety and aesthetic consistency.

Our heavy-duty Barbell Holder Attachment is engineered for seamless integration into commercial power racks and home gym systems. Utilizing high-grade steel and precision laser cutting, we provide comprehensive OEM services that transform your technical drawings into market-ready components.

HULK Metal delivers industrial-grade Weight Plate Tree manufacturing, transforming complex technical drawings into durable gym hardware. Our Bar and Weight Plate Tree OEM services prioritize structural integrity through advanced metalworking.

Our J Hooks and J Cups for Power Rack OEM services are designed for brands and wholesalers sourcing in volume. HULK Metal supports full-process manufacturing from drawings, covering stamping, welding, machining, and surface treatment under ISO 9001 control.

Fitness Equipment Extrusions are widely used for frames, rails, supports, and structural connectors in commercial gym equipment. HULK Metal provides OEM production covering extrusion forming, precision cutting, CNC machining, welding, and surface treatment.

HULK Metal provides Weight Plate Holder OEM services for global gym equipment brands and wholesalers seeking dependable large scale supply. From standard weight plate racks to custom bumper plate storage solutions, our factories support cutting, welding, bending, machining, and finishing under ISO 9001 systems.

Fitness Equipment Parts often involve complex structures, load-bearing requirements, and strict consistency standards. HULK Metal provides Custom Fitness Equipment Parts through OEM production, supporting drawings or samples.

Exercise equipment parts form the structural and functional backbone of modern fitness machines. HULK Metal offers OEM services focused on custom exercise equipment parts manufactured strictly to drawings.

HULK Metal crafts Custom Workout Equipment Parts to your exact drawings—no job too complex. With full in-house metal fabrication and strict ISO controls, we deliver stronger, smoother, and more consistent parts than typical suppliers.

HULK Metal Crafts Gym Equipment Components with tighter tolerances and heavier-duty builds than most. We handle OEM requests from start to finish—stamping, welding, laser cutting, and forging—all under one roof.

HULK Metal delivers high-quality custom barbell rack OEM services backed by decades of metal fabrication expertise. Our ISO 9001-certified factories handle everything from raw material sourcing to final delivery. Whether you need power racks, squat racks, or wall-mounted systems, we produce precise, durable parts that meet your exact specifications.

HULK Metal is a trusted OEM supplier of custom gym equipment rack and parts, backed by ISO 9001-certified factories and full-sheet metal production capabilities. We manufacture power racks, squat racks, wall-mounted systems, and more—exactly to your drawings.

HULK Metal produces custom power racks from iron, steel, stainless steel, and aluminum using sheet metal, profiles, pipes, and strips. Our processes include stamping, CNC machining, welding, casting, and forging.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU