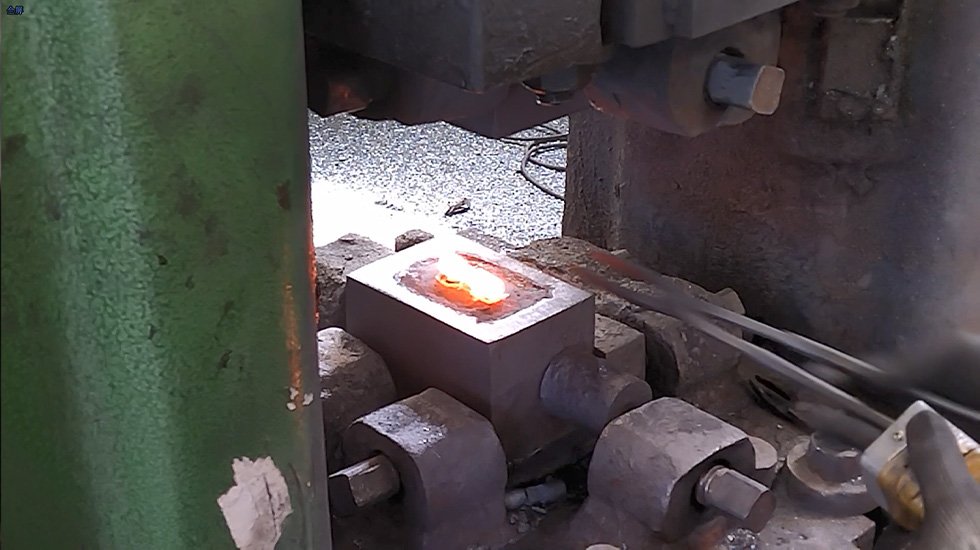

Metal forging companies are service-oriented enterprises that have rich forging factory resources or have their own forging factories and have professional teams that can develop detailed solutions according to the specific requirements of customers, from raw material procurement to final delivery of goods. Just like HULK Metal, we have been integrating supply chains and forming teams to provide forging OEM and ODM services to customers around the world since 2004. To date, we have served hundreds of products in more than 20 industries, such as automobiles, agricultural machinery, mining machinery, furniture and appliances, construction, and pipelines. We have rich forging factory resources, professional teams, and a fully equipped quality inspection center, and we will continue to grow and hope to help more customers complete their purchases in China.

EN

EN RU

RU