1. Higher Quality Precision Aluminum Die Casting Parts

2. Shorter Production Cycle

3. More Types of Surface Treatment

4. More Cost-Saving Freight Routes

5. More Comprehensive Service.

| Name | Precision Aluminum Die Casting Parts |

| Manufacturing | Manufacturing According to Drawings |

| Process | Die Casting → CNC Machining |

| CNC Machining | Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring |

| Materials | Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized |

| Surface | Anodized / Passivated / Polished / Powder Coating / Brushed / Customized |

| Certification | CE / ISO9001 / Others |

| Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized |

| Service | Freight consulting / Quality inspection / After-sales / Other value-added services. |

| Freight Way | Sea / Air / Land |

| Delivery Method | FOB / CIF / CFR / CPT / DDU / According to Requirement |

| Payment Method | TT / Negotiable |

| Quality Assurance | Life-Long |

You will get Precision Aluminum Die Casting Parts with more cost-saving freight routes. HULK Metal continues to integrate the supply chain, and freight is also an important part of the supply chain. After more than ten years of unremitting ability, we have reached close cooperation with dozens of world-renowned freight companies, not only can we plan more suitable freight routes for you, but also get better freight prices.

You will get the Higher Quality Precision Aluminum Die Casting Parts Accessories. HULK Metal's quality inspection team will track the production of the order, strictly inspect the physical and chemical properties and mechanical properties of raw materials, and inspect the shape, size and mechanical properties of finished products. The factory strictly implements the ISO9001 quality management system. The quality of your products is more guaranteed.

You will get Precision Aluminum Die Casting Parts with more types of surface treatment. HULK Metal's factory can provide a variety of surface treatment services such as anodizing, powder coating, sandblasting, polishing, wire drawing, etc. The quality inspection team will strictly inspect the surface finish and corrosion resistance of products to meet your requirements.

You will get the Precision Aluminum Die Casting Parts with a shorter production cycle. HULK Metal's experienced production team is skilled in operating aluminum die casting equipment and can provide a higher standard of production services. They can fill orders faster with lower defect rates. We will also provide you with timely feedback on the production progress in various ways.

You will enjoy more comprehensive service at HULK Metal. HULK Metal hopes to make your purchasing process easier by providing more thoughtful service. We have set up sales, procurement, technology, production, quality inspection, packaging, freight, and after-sales teams, which can solve the problems you encounter in the procurement process from all aspects.

Casting spare parts are metal workpieces with special shapes, sizes, and functions made from various metals using appropriate metal casting processes. HULK Metal integrates a complete metal foundry to complete casting spare parts that require sand casting, investment casting, lost foam casting, or die casting. Currently we can process metal parts made of ductile iron, gray iron, malleable cast iron, carbon steel, alloy steel, stainless steel, aluminum, etc. We have passed ISO9001 certification. The experienced technical team can develop a more complete solution based on your drawings and calculate a more competitive quotation. We provide QA services. Looking forward to your inquiry.

There are many forging parts suppliers in the world, and their company sizes vary, with different production capabilities and services. HULK Metal is one of the well-known forging parts suppliers in China. We have been providing forging parts production and export services to global customers since 2004 and have rich experience. We have a complete supply chain and service team to provide more thoughtful services, help solve more problems that arise during order production, and protect your rights and interests by providing after-sales service.

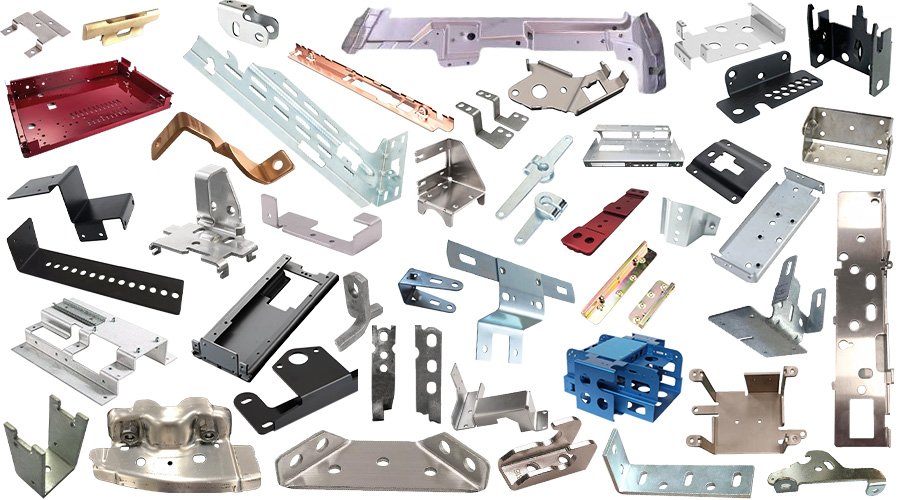

Metal stamping parts are metal components with special shapes, sizes and functions that are made of metal sheets by blanking, deep drawing, bending, punching and other processes. Common metal sheets are made of galvanized iron, galvanized steel, carbon steel, alloy steel, stainless steel, aluminum alloy, etc. HULK Metal is a Chinese supplier with an advanced sheet metal manufacturing plant. We can provide you with OEM and ODM services such as cutting, welding and stamping. We will sign an NDA agreement with you and provide after-sales service. You can rest assured to place your order with us.

Machined metal parts are components with more precision and special functions that are made by CNC machining centers using turning, milling, grinding, drilling, and other tools to process metal billets or semi-finished castings and forgings. They are widely used in the automotive, construction, and machinery industries and various other industries. HULK Metal is a China-machined metal parts supplier that can provide OEM and ODM services and make more perfect solutions according to your drawings and requirements to ensure faster delivery of goods with higher quality and better prices. We provide after-sales service; please rest assured to purchase.

Pump parts are the components that make up the pump, including the body, housing, cover, impellers, brackets, etc. Valve parts are composed of the body, handle, stem, gate (gate valve), disc (butterfly valve), ball (ball valve), etc. These metal parts are made of ductile iron, gray iron, carbon steel, alloy steel, stainless steel, and aluminum alloy through casting, forging, CNC processing, and other processes. HULK Metal has passed ISO 9001 certification and has been providing OEM and ODM services for pump and valve parts since 2004. Looking forward to your inquiry.

Name Aluminum Die Casting TV Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Seat Brackets

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Pump Covers

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting PC Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Motorcycle Accessories

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Name Aluminum Die Casting Motor Fan

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Heat Sink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting LED Light Cover

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Junction Box

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Heatsink

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Connectors

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Bicycle Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Cast Steel Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Steel

Process Investment Casting / Sand Casting / Lost Foam Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Tolerance(mm) Customized

Name Aluminum Die Casting Auto Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Aluminum Die Casting Accessories

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Name Aluminium Die Cast Enclosure

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Bicycle Casting Parts

Manufacturing Methods Manufacturing According to Drawings

Materials QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25) / SS (Stainless Steel) / Cast Iron / Die Casting Aluminum

Process Investment Casting / Sand Casting / Lost Foam Casting / Die Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Anodizing / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Aluminum Die Casting Washing Machine Bracket

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Name Precision Aluminum Die Casting Parts

Manufacturing According to Drawings

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2 / Customized

Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, High Pressure Casting/Sand Casting, Extrusion Casting etc.

TV / Monitor / Customized

Shot / sand blast / polishing / Primer Painting / Powder coating / ED- Coating / Finish Painting / Anodize (White or Black Color) / Customized

Power supply housing / Automotive Door Handle / Customized

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2 / Customized

Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, High Pressure Casting/Sand Casting, Extrusion Casting etc.

0.005mm / Customized

≤0.8 / Customized

Shot / sand blast / polishing / Primer Painting / Powder coating / ED- Coating / Finish Painting / Anodize (White or Black Color) / Customized

Name Agricultural Castings

Manufacturing Manufacturing According to Drawings

Process Investment Casting / Sand casting / Lost foam casting / Lost wax casting.

Material Cast iron / Cast steel / Forged steel / Customized

Surface Treatment Spraying / Hot-dip Galvanizing / Electro-Galvanizing / Customized

Name Automobile Casting Parts

Manufacturing Methods Manufacturing According to Drawings

Materials QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25) / SS (Stainless Steel) / Cast Iron / Die Casting Aluminum

Process Investment Casting / Sand Casting / Lost Foam Casting / Die Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Anodizing / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Agricultural Hammer Claw Casting Parts

Manufacturing Methods Manufacturing According to Drawings

Materials QT (Ductile Iron) HT (Grey Cast Iron) / Customized

Process Coated Sand Casting / Clay Sand Casting / Customized According to Products

Surface Treatment Powder Coating / Galvanized / Black

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

engine bracket, truck chassis bracket, gearbox, gear housing , gear cover, shaft, spline shaft, pulley, flange, connection pipe, pipe, hydraulic valve, valve housing, Fitting, flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft, transmission gear, sprocket, chains, etc.

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2 / Customized

Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, High Pressure Casting/Sand Casting, Extrusion Casting etc.

0.005mm / Customized

≤0.8 / Customized

Shot / sand blast / polishing / Primer Painting / Powder coating / ED- Coating / Finish Painting / Anodize (White or Black Color) / Customized

Name Agricultural Blade Guard Casting Parts

Manufacturing According to Drawings

Materials QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25) / Customized

Process Coated Sand Casting / Customized

Surface Treatment Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Packaging Wooden case / Carton / Bulk / Individually Packaged / Customized

Serivce Freight consulting / Quality inspection / After-sales / Other value-added services.

Delivery Method Sea / Air / Land

Quality Assurance Life Long

Name Water Glass Sand Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Gray Iron / Ductile Iron / Stainless Steel / Carbon Steel / Customized

Process Water Glass Sand Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Stainless Steel Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Stainless Steel

Process Investment Casting / Sand Casting / Lost Foam Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Resin Sand Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Gray Iron / Ductile Iron / Stainless Steel / Carbon Steel / Customized

Process Resin Sand Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Name Reducer Housing Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Ductile Iron / Gray Iron / Customized

Process Investment Casting / Sand Casting / Lost Foam Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape and position tolerance; 5. Surface roughness;

Name Precision Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Ceramic Mold Casting / Metal Mold Casting, Die Casting, Lost Foam Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Motorcycle Accessories Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Aluminum / Stainless Steel / Carbon Steel / Gray Iron / Customized

Process Investment Casting / Sand Casting / Lost Foam Casting / Die Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Lost Wax Foundry Casting

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Gray Iron / Ductile Iron / Stainless Steel / Carbon Steel / Customized

Process Lost Wax Foundry Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Lost Foam Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Gray Iron / Ductile Iron / Stainless Steel / Carbon Steel / Customized

Process Lost Foam Castings

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Investment Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Gray Iron / Ductile Iron / Stainless Steel / Carbon Steel / Customized

Process Investment Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Cast Iron Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron

Process Investment Casting / Sand Casting / Lost Foam Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Name Ductile Iron Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Ductile Iron

Process Investment Casting / Sand Casting / Lost Foam Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Tolerance(mm) Customized

Name Drain Pipe Casting Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Ductile Iron / Gray Iron

Process Investment Casting / Sand Casting / Lost Foam Casting / Customized

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Tolerance(mm) Customized

Name Centrifugal Casting Castings

Manufacturing Methods Manufacturing According to Drawings

Materials Cast Iron / Stainless Steel / High Manganese Steel / Customized

Process Centrifugal Casting

Surface Treatment Sandblasting / Shot Blasting / Powder Coating / Customized

Test Content & Data 1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Tolerance(mm) Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304 / 316L / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Hot Forging

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Stainless Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Stainless Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Motorcycle Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Manufacturing According to Drawings

Process Hot Forging / Die Forging / Custom

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Name Motorcycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Mining Machinery Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Die Forging / Customized

Name Hot Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Customized

Process Hot Forging

Name Cold Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials 20Cr Steel / 20CrMo Steel / 20CrMnTi Steel /Aluminum / Aluminum Alloy / Customized

Process Cold Forging

Name Carbon Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel

Process Hot Forging / Free Forging / Mold Forging / Ring Forging / Customized

Name Bicycle Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Parts Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Auto Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Aluminum / Customized

Process Hot Forging / Cold Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Alloy Steel Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Alloy Steel

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Rilling Forging / Die Forging / Customized

Name Agricultural Machinery Accessories Forging Parts

Manufacturing Methods Manufacturing According to Drawings

Materials Carbon Steel / Alloy Steel / Stainless Steel / Customized

Process Hot Forging / Free Forging / Mold Forging / CNC Machining / Customized

HULK Metal is a manufacturer of sheet metal stamping parts in China. We have advanced stamping equipment, experienced workers, and perfect after-sales service to complete higher-quality orders faster at a lower price.

HULK Metal is committed to providing high-quality sheet metal automotive parts OEM services to customers around the world. We have a complete supply chain to provide you with better OEM services.

HULK Metal has developed over 16 years to become an experienced metal stamping manufacturer. We can manufacture higher quality steel metal stamping parts from carbon steel, stainless steel, and alloy steel. We have a complete quality control system.

HULK Metal has provided excellent metal stamping services to hundreds of stainless steel metal stamping parts purchasers around the world. Our products have been used in more than 20 industries, such as automobile manufacturing, machinery manufacturing, home appliance manufacturing, construction industry, etc.

HULK Metal is a professional manufacturer of home appliance metal stamping parts that has provided metal stamping services for the home appliance manufacturing industry for over 16 years.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

As a metal stamping service supplier with a strong production capacity, HULK Metal has 5 sets of stamping machines with a capacity of 315 tons, 5 sets of 200 tons capacity, 5 sets of 80 tons capacity and 5 sets of 60 tons capacity. We can provide customized manufacturing services for copper metal stamping parts of 0.1mm~10mm. Products can be certified by CE, SGS, GB, and other standards.

HULK Metal has 20 precision stamping machines that can process precision metal stamping parts from 0.05mm to 5mm. Our quality inspection team will strictly test the performance and parameters of the product to ensure that the quality of the product can meet your requirements.

HULK Metal has provided excellent metal stamping services for more than 20 industries such as automobiles, home appliances, machinery, and other manufacturing or construction industries.

HULK Metal has an experienced technical team that can customize complete metal stamping parts OEM solutions. We can supply products certified by CE, SGS, etc. and comprehensive services such as shipping and after-sales.

HULK Metal is an experienced manufacturer of concrete precast metal stamping parts. We have been manufacturing spread anchors, connectors, and other concrete precast metal stamping parts since the second half of the 20th century.

HULK Metal is a professional manufacturer of metal stamping parts. Our factory has more automated stamping machines and advanced product quality inspection instruments so that we can complete higher quality carbon steel metal stamping parts faster.

HULK Metal provides professional brass metal stamping services with full-process technical support and production capacity. We specialize in manufacturing custom brass metal stamping parts that meet CE, GB, and SGS standards.

HULK Metal's factory has 20 stamping machines, 10 CNC machines, and perfect-quality inspection instruments. We can provide complete OEM services for metal stamping parts. We can manufacture metal stamping parts in automobiles, construction, household appliances, and other industries with copper, steel, and aluminum as raw materials.

HULK Metal is a professional Auto Accessories Metal Stamping Parts manufacturer with over 16 years of experience. We have a complete supply chain to supply you with complete metal stamping OEM services.

HULK Metal has been engaged in the manufacture of Aluminum Sheet Metal Stamping Parts for many years. We focus more on the needs of our customers and develop complete production solutions accordingly.

HULK Metal has been engaged in the stamping service of aluminum metal parts since the second half of the 20th century. Up to now, HULK Metal has been able to produce metal stamping parts with a thickness of 0.1mm~2mm using 1000~7000 aluminum alloy plates as raw materials.

Aluminum Alloy 6063 / Customized

Profile Extrusion / Cutting / Deburring / CNC Process / Customized

Air conditioner / Frequency Converter / Communication Base Station / Computer / Electric Equipment / Customized

CE / ISO / RoHS / SGS / Customized

Anodizing / Sand Blasting / Painting / Chormating / Customized

Trademark printing / wooden box / plastic box / foam box / air film / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Material ND Steel / Cast steel / Stainless steel / Carbon steel / Customized

Name CNC Machining Aluminum Die Casting Parts

Manufacturing According to Drawings

Materials Al-Mg Alloy / Al-Zn Alloy / Al-Si Alloy / Customized

Surface Anodized / Passivated / Polished / Powder Coating / Brushed / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping / CNC Machining

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Material ND Steel / Cast steel / Stainless steel / Carbon steel / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Material ND Steel / Cast steel / Stainless steel / Carbon steel / Aluminum Alloy / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping / CNC Machining

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials 304L / 316L / Aluminum Alloy / / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Surface Spraying / Hot Galvanizing / Electro Galvanizing / BAlack / Anodizing / Customized

Manufacturing According to Drawings

Process Casting / Forging / Stamping

CNC Machining Turning, Milling, Planing, Drilling, Grinding, Drilling, Boring

Materials Carbon Steel / ND Steel / Stainless Steel / Aluminum Alloy / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Sewage Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Housing

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Housing: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Housing: precision casting, lost wax casting.

Powder spraying, Painting

Sewage Pump Bases

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Sewage Pump Bases: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Sewage Pump Bases: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline pump Motor Bracket

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline pump Motor Bracket: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline pump Motor Bracket: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Impellers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Covers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Covers: precision casting, lost wax casting.

Powder spraying, Painting

Pipeline Pump Housings

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Pipeline Pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Pipeline Pump Housings: precision casting, lost wax casting.

Powder spraying, Painting

Centrifugal Pump Impellers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump impellers: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump impellers: precision casting, lost wax casting.

Powder spraying, Painting

1. Chemical composition; 2. Mechanical properties; 3. Metallographic inspection; 4. Inspection of appearance, size, shape, and position tolerance; 5. Surface roughness;

Centrifugal Pump Covers

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump covers 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump covers: precision casting, lost wax casting.

Powder spraying, Painting

Name Centrifugal Pump Bottom Plates

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron Centrifugal Pump Bottom Plates: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel Centrifugal Pump Bottom Plates: precision casting, lost wax casting.

Powder spraying, Painting

Manufacturing According to Drawings

QT (Ductile Iron) HT (Grey Cast Iron) Cast Steel (ZG25)

Gray cast iron, ductile iron pump Housings: 1. Resin sand casting; 2. Lost foam casting; 3. Coated sand casting;

Cast steel pump Housings: precision casting, lost wax casting.

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

Ductile Iron / Stainless Steel / Gray Iron / Cast Steel / Customized

+/-0.01mm

CT9

Casting / CNC / Customized

≥1.6Mpa, ≤6.4Mpa

Painting / Plating / Polishing / Customized

Anti-collision / Brand Logo / Customized

CB / CE / URV / Customized

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU