As one of the excellent magnetic recess former suppliers in China, HULK Metal has advanced factories and perfect supply chain to provide you with high-quality products and services.

Precast concrete magnets are one of HULK Metal's main products. They are recognized by customers for their high quality and reasonable price. Precast concrete magnets use high-performance and durable NdFeB alloy magnets. Advanced technology effectively improves production efficiency and reduces costs while ensuring its quality. We provide quality assurance services. You can purchase them with confidence.

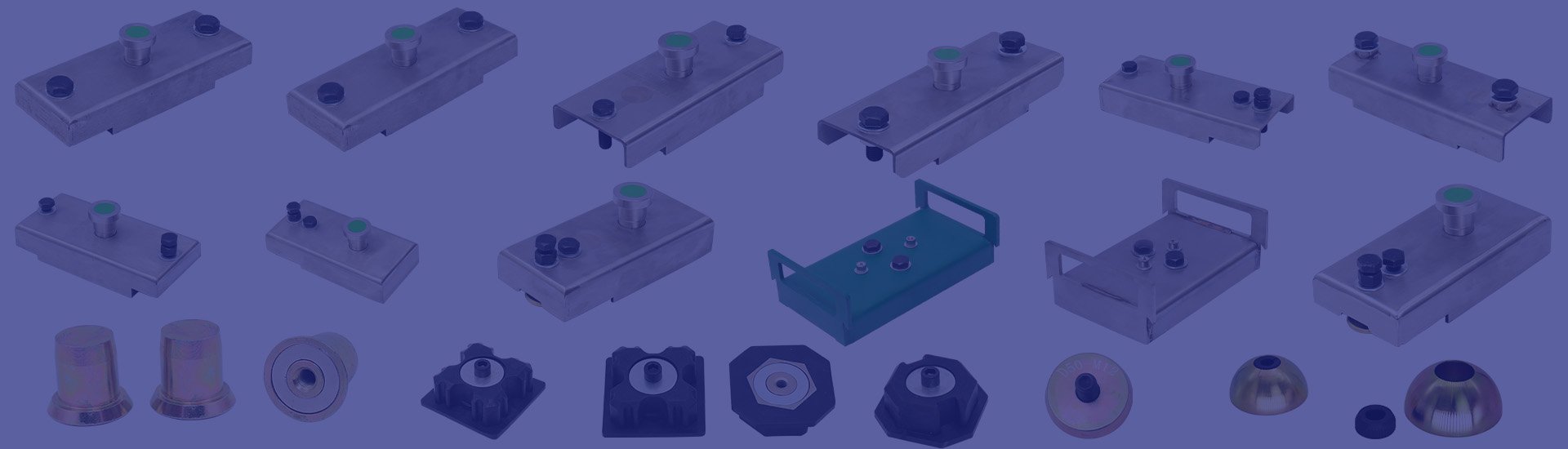

Precast Concrete Magnets are specially designed tools used in precast concrete production to securely hold formwork, electrical boxes, embedded corrugated pipes, and other precast accessories in place during casting. They are manufactured with high-performance NdFeB alloy magnets that provide strong and durable magnetic force, making them reliable for repeated use. With proper handling, high-quality Precast Concrete Magnets can be used almost indefinitely, and only the metal shell may need to be replaced after long-term operation. Their simple structure, reusability, and cost-effectiveness make them a preferred choice for precast factories seeking efficiency and consistency. By reducing manual fixing work, they save labor time, enhance accuracy, and improve overall production efficiency. HULK Metal, as a professional Precast Concrete Magnets supplier in China, offers products with strict quality assurance, giving bulk buyers greater confidence in long-term cooperation and stable supply.

HULK Metal provides a wide selection of Precast Concrete Magnets in different types and sizes to meet various construction requirements. These magnets can be used for fixing precast concrete accessories, shuttering, electrical boxes, and embedded corrugated pipes, offering reliable performance across multiple applications. All products are produced under ISO 9001 certified processes, ensuring consistent quality and safety. With comprehensive production capabilities and strict testing, we supply Precast Concrete Magnets that help bulk buyers achieve more efficient and secure precast solutions.

As one of the excellent magnetic recess former suppliers in China, HULK Metal has advanced factories and perfect supply chain to provide you with high-quality products and services.

HULK Metal can provide CE-certified magnets for precast lifting and fixing inserts or sockets. Our factory has advanced machining equipment, laser cutting machines, and assembly lines, which can more efficiently complete CE-certified precast lifting fixing insert socket magnet with a higher pass rate.

HULK Metal's Electrical Box Fixed Magnets feature a durable rubber body combined with strong NdFeB magnets, ensuring reliable fixation of electrical boxes in precast concrete. These magnets are customizable in shape, size, and finish, providing flexibility for bulk orders.

Our Shuttering Magnets for Formwork are designed for precast concrete production, offering reusable and stable fixing solutions. They support different mold sizes and deliver better cost-efficiency for large-scale construction projects.

Our Embedded Corrugated Pipe Fixed Magnet combines premium steel housing with powerful magnets to ensure strong fixation during precast concrete production. It reduces installation time, improves efficiency, and provides consistent performance across different applications, helping customers achieve safer and more reliable concrete elements.

HULK Metal conducts strict quality control for every batch of Precast Concrete Magnets. Our inspection process includes raw material testing, dimensional measurement, magnetic force testing, pre-shipment inspection, and customized checks based on customer requirements. Detailed reports are provided.

Each Precast Concrete Magnet is made with carefully selected NdFeB materials. We test their strength, durability, and stability to ensure only qualified raw materials enter the production process.

We simulate actual usage conditions to test the magnetic force of every Precast Concrete Magnet. This ensures long-lasting holding power and reliable performance throughout repeated applications.

All magnets undergo precise dimensional measurement with advanced instruments. This guarantees each piece matches the required specifications, ensuring consistent performance and compatibility with different precast concrete applications.

Before delivery, we conduct comprehensive inspections including surface condition, packaging, and overall quality. This guarantees that every Precast Concrete Magnet you receive meets international standards.

According to customer requirements, we can provide customized testing services, including load capacity tests or special environmental simulations, ensuring the Precast Concrete Magnets perform well under specific working conditions.

HULK Metal integrates multiple factories to provide strong supply chain support for Precast Concrete Magnets. From injection molding to magnet production and precision assembly, every process is carried out under strict quality management. Our in-house quality inspection center ensures that each magnet meets international standards. With comprehensive production capacity, we can deliver consistent quality, shorter lead times, and flexible customization options to support bulk buyers worldwide.

Our production factory integrates magnet cores with molded shells, assembling them into finished Precast Concrete Magnets. Equipped with modern machinery and skilled workers, we can handle both large-scale orders and special customization requests. The assembly process is standardized to ensure every magnet has stable performance and consistent quality. We adopt efficient scheduling systems to shorten production cycles while maintaining accuracy. This enables us to deliver bulk orders faster and support our customers’ continuous and efficient precast concrete projects.

The quality inspection center is equipped with advanced testing instruments to carry out comprehensive checks on Precast Concrete Magnets. We test raw materials, dimensions, magnetic force, durability, and surface condition for each batch. Simulated application tests are performed to ensure reliable holding power in real precast environments. Detailed inspection reports are provided to customers for transparency. By maintaining strict control at every stage, our quality inspection center ensures that bulk buyers receive only high-quality Precast Concrete Magnets with guaranteed performance.

HULK Metal provides bulk buyers with reliable, high-quality Precast Concrete Magnets backed by extensive production and factory resources. Our products combine durable magnet cores, precise molding, and strict quality inspection to ensure consistent performance. With competitive pricing, fast delivery, and customizable options, we support large-scale precast projects efficiently. Choosing HULK Metal means access to professional service, comprehensive manufacturing capabilities, and peace of mind throughout the procurement process.

Our Precast Concrete Magnets are crafted with high-performance NdFeB magnets and durable metal or plastic shells, ensuring long-lasting strength and stability. Each magnet undergoes rigorous quality checks, including dimensional measurement and magnetic force testing, guaranteeing reliable performance for repeated use. By focusing on advanced production techniques and precision assembly, we deliver products that consistently meet international standards. Bulk buyers can trust that every magnet will maintain superior holding power, providing safer and more efficient precast concrete operations.

With multiple specialized factories and streamlined production processes, HULK Metal delivers Precast Concrete Magnets quickly and efficiently. Optimized scheduling and efficient assembly reduce lead times, supporting urgent and large-volume orders. Our logistics team coordinates shipment to ensure products arrive safely and on time, minimizing delays in construction projects. By choosing HULK Metal, bulk buyers can maintain uninterrupted workflow, accelerate project timelines, and avoid costly downtime while still receiving high-quality Precast Concrete Magnets.

Our comprehensive production, inspection, and customization services simplify procurement for bulk buyers. By handling raw material selection, magnet manufacturing, assembly, and quality control internally, we reduce the need for multiple suppliers. Detailed inspection reports and reliable product performance allow clients to plan and execute precast projects with confidence. Partnering with HULK Metal saves time, reduces operational complexity, and minimizes energy spent on quality verification, enabling bulk buyers to focus on core construction tasks efficiently.

HULK Metal offers competitive pricing without compromising quality. By integrating factories and controlling production processes internally, we reduce costs and pass the savings directly to our customers. Bulk buyers benefit from cost-effective solutions for large-scale precast projects, making procurement more efficient. Our transparent pricing ensures clients understand the value of every order, and flexible packaging or quantity options further optimize costs. Choosing us allows customers to achieve both high-quality performance and better profitability.

HULK Metal provides additional resources and insights related to Precast Concrete Magnets, including practical applications, installation tips, and maintenance guidelines. Customers can also access information about related precast accessories, such as shuttering components, electrical boxes, and embedded corrugated pipes. These resources help bulk buyers make informed purchasing decisions and optimize precast operations. By showcasing product features, use cases, and complementary accessories, we ensure clients have a comprehensive understanding of how our Precast Concrete Magnets enhance efficiency, reliability, and quality in large-scale precast concrete projects.

As a top metalworking service provider, we want to let every customer experience a sense of security in purchasing, sales, etc., and better realize their value through continuously defining new standards for products and services.

Room 901, Intelligent Park A Building, No. 86 ChunYang Rd, Qingdao, China 266109

© 2025 HULK Metal All Rights Reserved. All Rights Reserved.

EN

EN RU

RU